Special impregnating agent for basalt fiber

A technology of basalt fiber and sizing agent, which is applied in the field of reinforced fiber sizing agent and its preparation, can solve the problems of poor film-forming performance, flying silk and hairiness phenomenon, poor resin binding force, etc., and achieves good film-forming performance and good protection. effect, strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

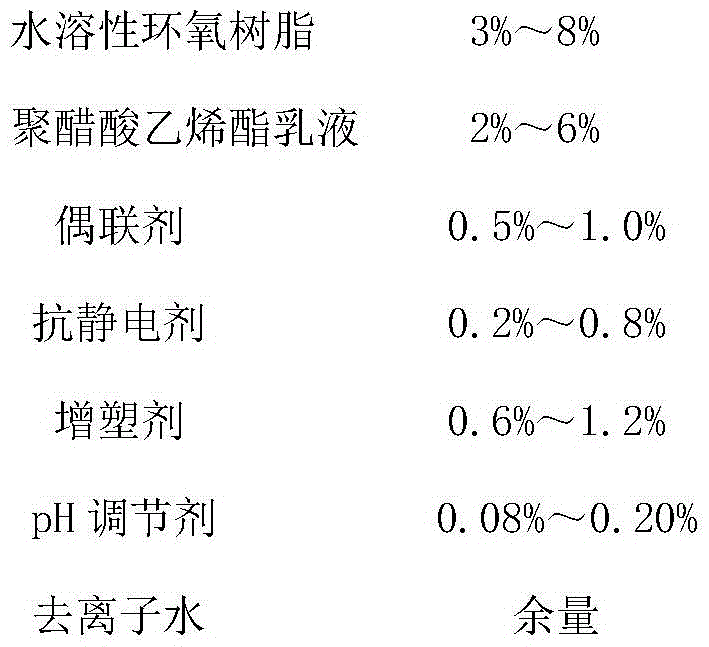

[0026] A special-purpose epoxy-type sizing agent for basalt fiber, which consists of the following components in terms of weight percentage:

[0027]

[0028] Preparation steps:

[0029] a. Add the polyvinyl acetate emulsion into the water and stir evenly, the water temperature is 50-70 degrees; the amount of water is 5-10 times of the weight of the polyvinyl acetate emulsion for later use;

[0030] b. Add the water-soluble epoxy resin into the water and stir evenly, the water temperature is 50-70 degrees; the amount of water is 5-10 times the weight of the water-soluble epoxy resin for later use;

[0031] c. Add a pH regulator in deionized water to adjust the pH value to 4-6, add aminosilane coupling agent under stirring, and continue stirring for 25-35 minutes until the aqueous solution is clear and transparent; the amount of water accounts for 10% of the total weight of the wetting agent 1 / 20;

[0032] d. Dissolving the antistatic agent into an aqueous solution at a ma...

Embodiment 2

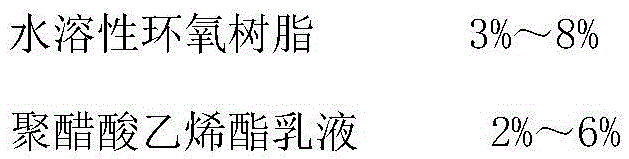

[0035] A special-purpose epoxy-type sizing agent for basalt fiber, which consists of the following components in terms of weight percentage:

[0036]

[0037]

[0038] Preparation steps:

[0039] a. Add the polyvinyl acetate emulsion into the water and stir evenly, the water temperature is 50-70 degrees; the amount of water is 5-10 times of the weight of the polyvinyl acetate emulsion for later use;

[0040] b. Add the water-soluble epoxy resin into the water and stir evenly, the water temperature is 50-70 degrees; the amount of water is 5-10 times the weight of the water-soluble epoxy resin for later use;

[0041] c. Add a pH regulator in deionized water to adjust the pH value to 4-6, add aminosilane coupling agent under stirring, and continue stirring for 25-35 minutes until the aqueous solution is clear and transparent; the amount of water accounts for 10% of the total weight of the wetting agent 1 / 20;

[0042] d. Dissolving the antistatic agent into an aqueous solu...

Embodiment 3

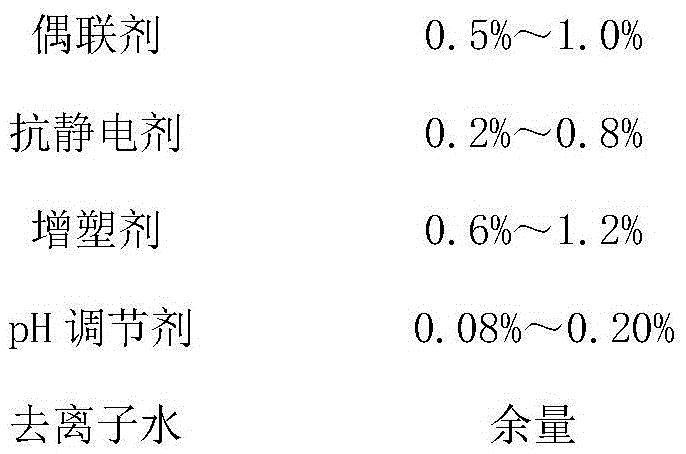

[0045] A special-purpose epoxy-type sizing agent for basalt fiber, which consists of the following components in terms of weight percentage:

[0046]

[0047] Preparation steps:

[0048] a. Add the polyvinyl acetate emulsion into the water and stir evenly, the water temperature is 50-70 degrees; the amount of water is 5-10 times of the weight of the polyvinyl acetate emulsion for later use;

[0049] b. Add the water-soluble epoxy resin into the water and stir evenly, the water temperature is 50-70 degrees; the amount of water is 5-10 times the weight of the water-soluble epoxy resin for later use;

[0050] c. Add a pH regulator in deionized water to adjust the pH value to 4-6, add aminosilane coupling agent under stirring, and continue stirring for 25-35 minutes until the aqueous solution is clear and transparent; the amount of water accounts for 10% of the total weight of the wetting agent 1 / 20;

[0051] d. Dissolving the antistatic agent into an aqueous solution at a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com