Method for preparing porous alpha-Fe2O3 photo-anode

A technology of photoanode and thin film, applied in the direction of coating, electrolysis process, electrolysis components, etc., can solve the problems of complicated and expensive preparation process, low photoelectrode performance, etc., and achieve the effect of simple preparation method, easy operation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

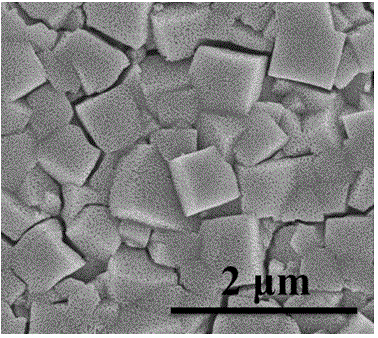

Embodiment 1

[0025] Porous α -Fe 2 o 3 The preparation steps of the photoanode include: ultrasonically cleaning the FTO sheet with acetone and absolute ethanol for 20 minutes to remove chemical oil stains, then rinsing with deionized water, and air-drying for later use; and 6.0 mu mol of isopropyl titanate was dissolved in 20mL deionized water; the solution was transferred to a stainless steel reactor with a volume of 30mL lined with polytetrafluoromaterial, and a piece of size 2×4cm 2 Place the clean FTO sheet in the reaction kettle and react at 100°C for 10h. After the reaction, let it cool naturally. , then place it flat in a porcelain boat pre-installed with graphite, and heat it in a microwave oven for 12 minutes to obtain the porous α -Fe 2 o 3 film.

Embodiment 2

[0027] Porous α -Fe 2 o 3 The preparation steps of the photoanode include: ultrasonically cleaning the FTO sheet with acetone and absolute ethanol for 20 minutes to remove chemical oil stains, then rinsing with deionized water, and air-drying for use; 15mmol of ferric nitrate, 7.5mmol of Isopropyl titanate was dissolved in 15mL deionized water, and the solution was transferred to a 30mL stainless steel reaction kettle lined with polytetrafluoro material, and a piece of size 2×4cm 2 Place the clean FTO in the reaction kettle and react at 80°C for 24h. After the reaction, let it cool naturally. , then place it flat in a porcelain boat pre-installed with silicon carbide powder, and heat it in a microwave oven for 3 minutes to obtain the porous α -Fe 2 o 3 film.

Embodiment 3

[0029] Porous α -Fe 2 o 3 The preparation steps of the photoanode include: ultrasonically cleaning the FTO sheet with acetone and absolute ethanol for 20 minutes to remove chemical oil stains, then rinsing it with deionized water, and drying it naturally for use; Dissolve 0.3mmol of titanium oxychloride in 24mL of deionized water, transfer the solution to a 30mL stainless steel reaction kettle lined with polytetrafluoromaterial, take a piece with a size of 2×4cm 2 Place the clean FTO in the reaction kettle and react at 120°C for 4 hours. After the reaction, let it cool naturally. , put it flat in a porcelain boat pre-installed with silicon carbide powder, and heat it in a microwave oven for 20 minutes to obtain the porous α -Fe 2 o 3 film.

[0030] prepared porous α -Fe 2 o 3 The photoanode is used in photoelectric water splitting. The test conditions for its performance: In the three-electrode system, 1.0mol / L NaOH aqueous solution is the electrolyte solution, α -Fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com