Concrete tackifying and water retaining agent and preparation method and application thereof

A water-retaining agent and concrete technology, which is applied in the field of concrete tackifying and water-retaining agent, can solve the problems of insufficient concrete slurry, increased water-cement ratio, poor concrete cohesion, etc., and achieves high engineering application value, improved compressive strength, good work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

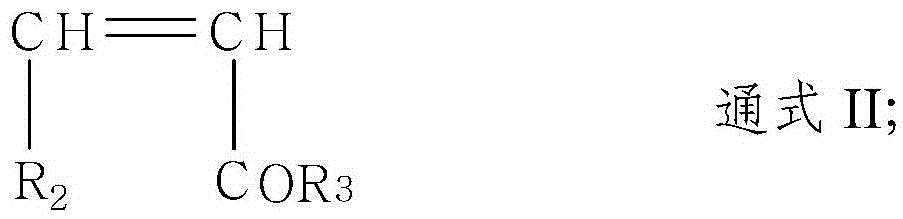

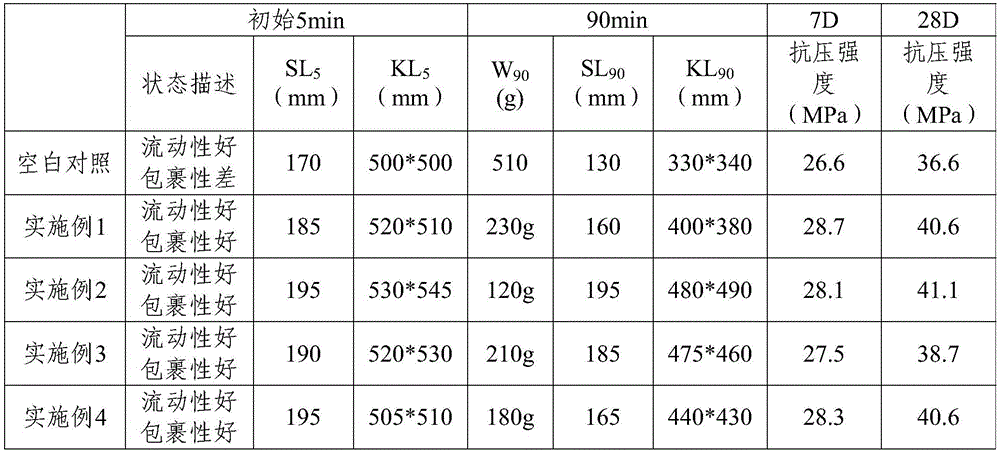

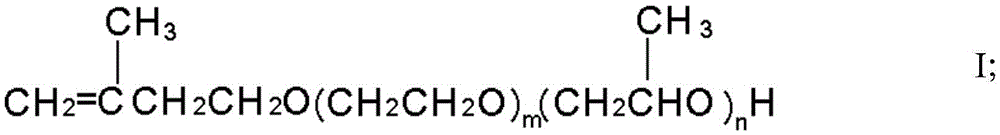

[0039] This embodiment provides a concrete viscosity-increasing and water-retaining agent, which is polymerized from the following raw materials: 50 g of methene butyl polyethylene glycol monopropylene glycol (corresponding to n=1 in general formula I) with a molecular weight of 2000, 75 g of acrylic acid, 2 - 20 g of methacrylamide-3-propenesulfonic acid, 5 g of vinyltris(2-methoxyethoxy)silane.

[0040]The concrete viscosity-increasing and water-retaining agent is prepared by the following specific steps: dissolve each raw material in 650 g of deionized water, and after the temperature is raised to 45° C., 83.5 g of persulfate solution with a concentration of 4.1% and 83.5 g of persulfate solution and Concentration is 1.8% L-ascorbic acid solution 81.5g, when dropping, control the temperature within 65°C, dropwise is completed within 3 hours, continue to keep warm at 65°C for 60 minutes to fully carry out the polymerization reaction; cool down after the reaction is completed,...

Embodiment 2

[0042] This embodiment provides a concrete viscosity-increasing and water-retaining agent, which is polymerized from the following raw materials: 50 g of methenebutyl polyethylene glycol (corresponding to n=0 in general formula I) with a molecular weight of 2000, 70 g of acrylamide, styrene Sodium sulfonate 25g, vinyl tris (2-methoxyethoxy) silane 5g.

[0043] The viscosity-increasing and water-retaining agent is prepared by the following specific steps: dissolve each raw material in 650g of deionized water, and after heating up to 45°C, simultaneously dropwise add 83.5g of persulfate solution with a concentration of 4.1% and a concentration of It is 81.5g of 1.8% L-ascorbic acid solution, the temperature is controlled within 65°C during the dropwise addition, and the dropwise addition is completed within 3 hours, and the temperature is kept at 65°C for 60 minutes to fully carry out the polymerization reaction; after the reaction is completed, cool and add 1000g of water, Add ...

Embodiment 3

[0045] This embodiment provides a concrete viscosity-increasing and water-retaining agent, which is polymerized from the following raw materials: 25g of methenebutyl polyethylene glycol (corresponding to n=0 in general formula I) with a molecular weight of 1000, 60g of acrylic acid, and 50g of acrylamide , sodium propylene sulfonate 15g, vinyltrimethoxysilane 0.5g.

[0046] The viscosity-increasing and water-retaining agent is prepared by the following specific steps: dissolve each raw material in 650g of deionized water, and after heating up to 45°C, simultaneously dropwise add 83.5g of persulfate solution with a concentration of 4.1% and a concentration of It is 81.5g of 1.8% L-ascorbic acid solution, the temperature is controlled within 65°C during the dropwise addition, and the dropwise addition is completed within 3 hours, and the temperature is kept at 65°C for 60 minutes to fully carry out the polymerization reaction; after the reaction is completed, cool and add 1000g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com