Method for preparing titanium dioxide nanosheet coated graphene anode material of lithium ion battery

A graphene anode and lithium ion battery technology, applied in the field of electrochemical materials, can solve the problems of titanium dioxide electrochemical performance not reaching an ideal level, slow lithium ion diffusion rate, poor conductivity, etc., achieve good application development prospects, improve lithium storage. Specific capacity, the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the preparation method of titanium dioxide nanosheet coated graphene negative electrode material, comprises the following steps:

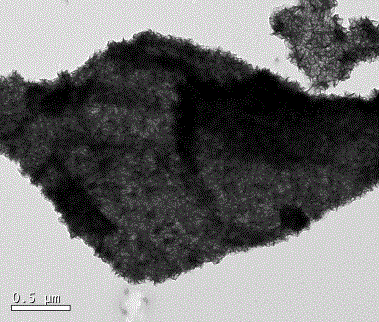

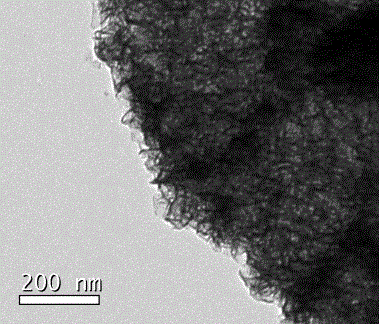

[0030] Graphite oxide was prepared by the hummer method, 30 mg of graphite oxide was sonicated in 30 mL of isopropanol for 4 hours with a 250 W ultrasonic instrument to form a graphene oxide suspension, then 0.02 mL of diethylenetriamine was added, stirred evenly, and 1.0 mL of titanic acid was added dropwise Butyl ester, stirred evenly, put into a 50mL reaction kettle, reacted at 180°C for 24 hours, washed the solvothermal reaction product with de-ethanol, dried, and treated at 500°C for 2 hours under a nitrogen atmosphere to obtain titanium dioxide nanosheet-coated graphite vinyl material.

[0031] The electrochemical performance test of the titanium dioxide nanosheet coated graphene material prepared in embodiment 1:

[0032] Mix the titanium dioxide nanosheet-coated graphene material prepared in Example 1 with conductive c...

Embodiment 2

[0038] Embodiment 2, the preparation method of titanium dioxide nanosheet coated graphene negative electrode material, comprises the following steps:

[0039]Graphite oxide was prepared by the hummer method, 25 mg of graphite oxide was sonicated in 30 mL of isopropanol for 4 hours with a 250 W ultrasonic instrument to form a graphene oxide suspension, then 0.025 mL of diethylenetriamine was added, stirred evenly, and 1.2 mL of titanic acid was added dropwise Butyl ester, stirred evenly, put into a 50mL reaction kettle, reacted at 180°C for 24 hours, washed the solvothermal reaction product with de-ethanol, dried, and treated at 500°C for 2 hours under a nitrogen atmosphere to obtain titanium dioxide nanosheet-coated graphite vinyl material.

[0040] The electrochemical performance test method of the titanium dioxide nanosheet coated graphene material prepared by embodiment 2 is the same as embodiment 1:

[0041] The XRD pattern of the material ( image 3 ) is attributed to t...

Embodiment 3

[0042] Embodiment 3, the preparation method of titanium dioxide nanosheet coated graphene negative electrode material, comprises the following steps:

[0043] Graphite oxide was prepared by the hummer method, 20 mg of graphite oxide was sonicated in 30 mL of isopropanol for 4 hours with a 250 W ultrasonic instrument to form a graphene oxide suspension, then 0.015 mL of diethylenetriamine was added, stirred evenly, and 1.0 mL of titanic acid was added dropwise Butyl ester, stirred evenly, put it into a 50mL reactor, reacted at 180°C for 24 hours, washed the solvothermal reaction product with ethanol, dried, and treated at 600°C for 2 hours under a nitrogen atmosphere to obtain titanium dioxide nanosheet-coated graphite vinyl material.

[0044] The electrochemical performance test of the titanium dioxide nanosheet coated graphene material prepared in embodiment 3:

[0045] Test method is identical with embodiment 1:

[0046] from Image 6 It can be seen that the material has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com