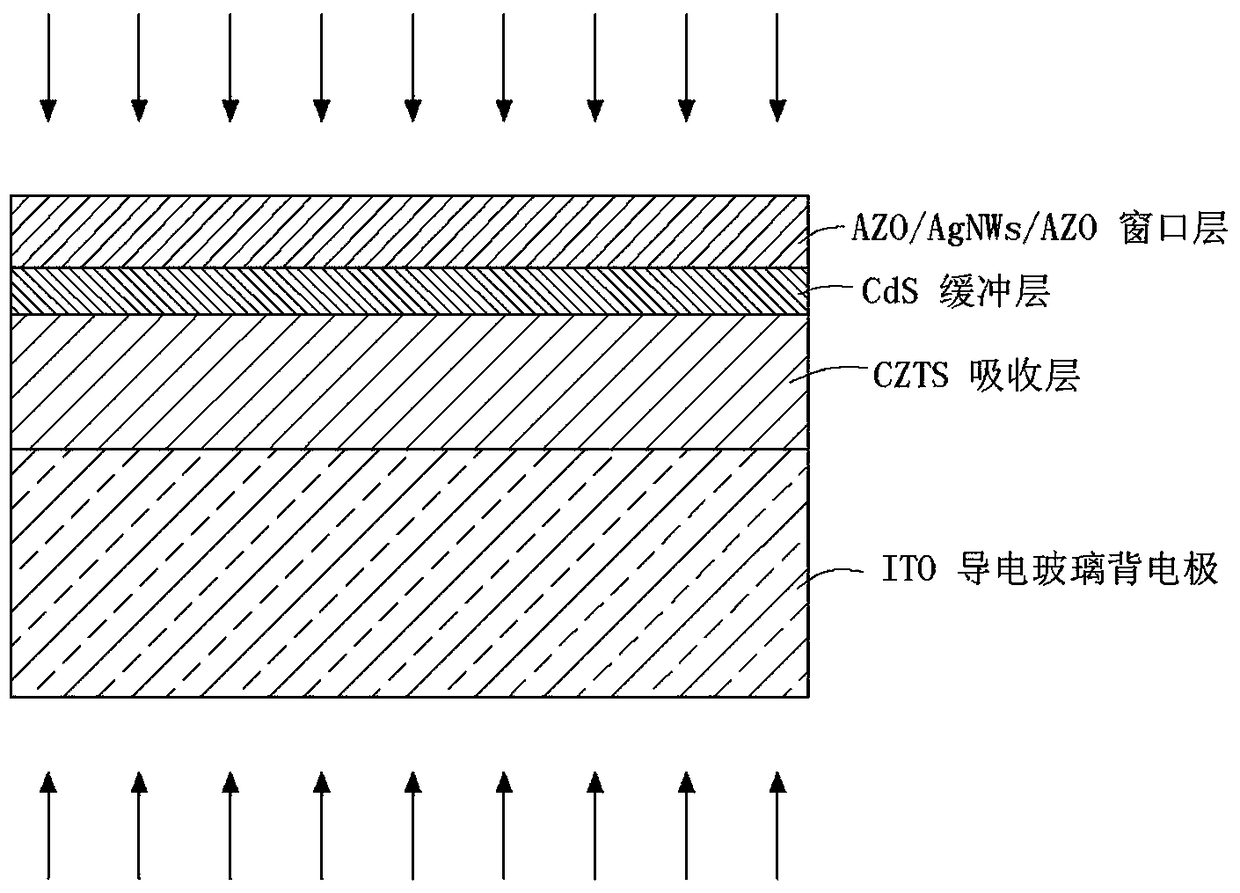

Copper zinc tin sulfur thin film solar cell and preparation method thereof

A solar cell, copper-zinc-tin-sulfur technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as limiting application, reducing device performance, destroying p-n junction interface performance, etc., to improve electrical performance, improve absorption capacity, Environmentally friendly effects of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

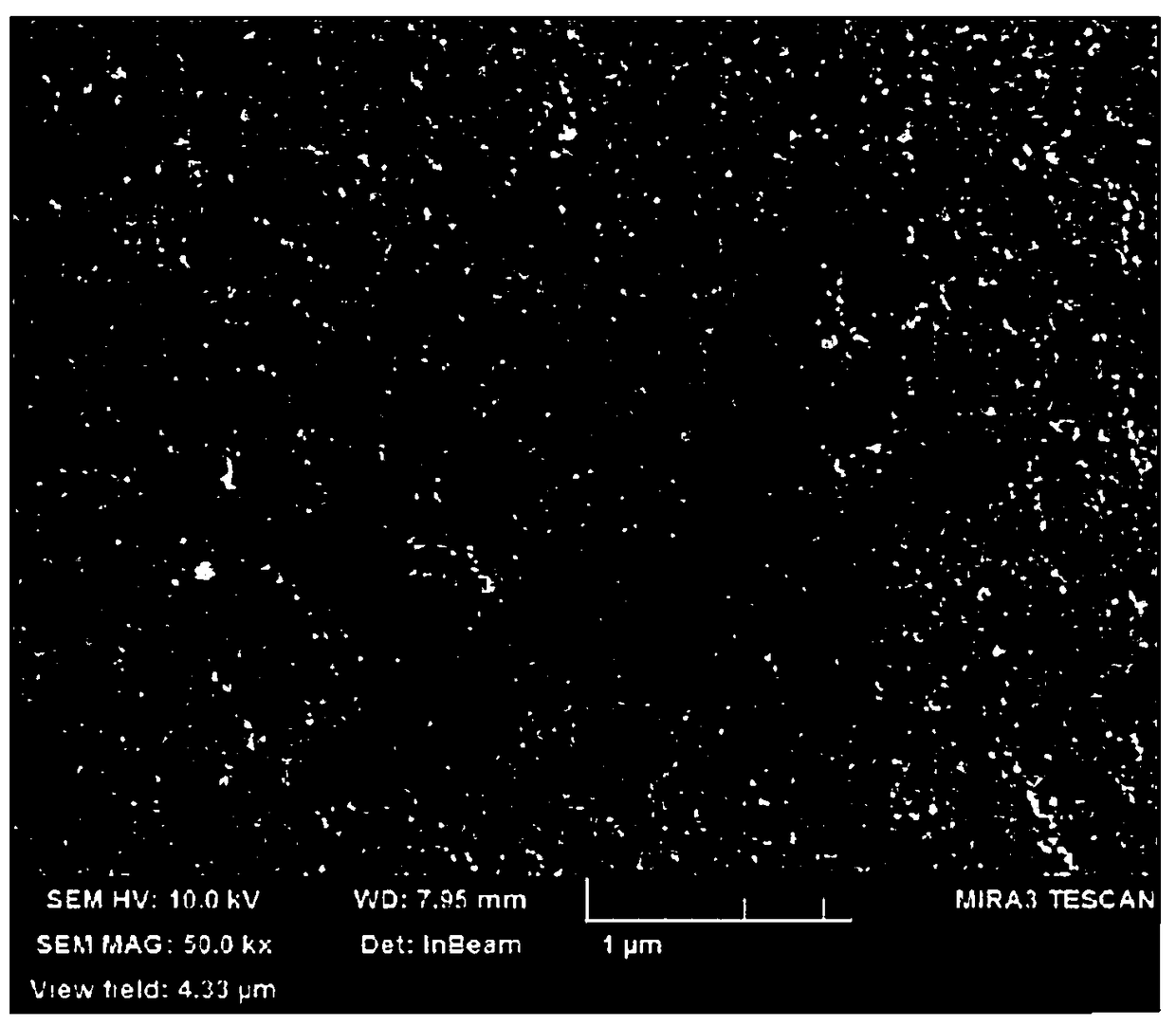

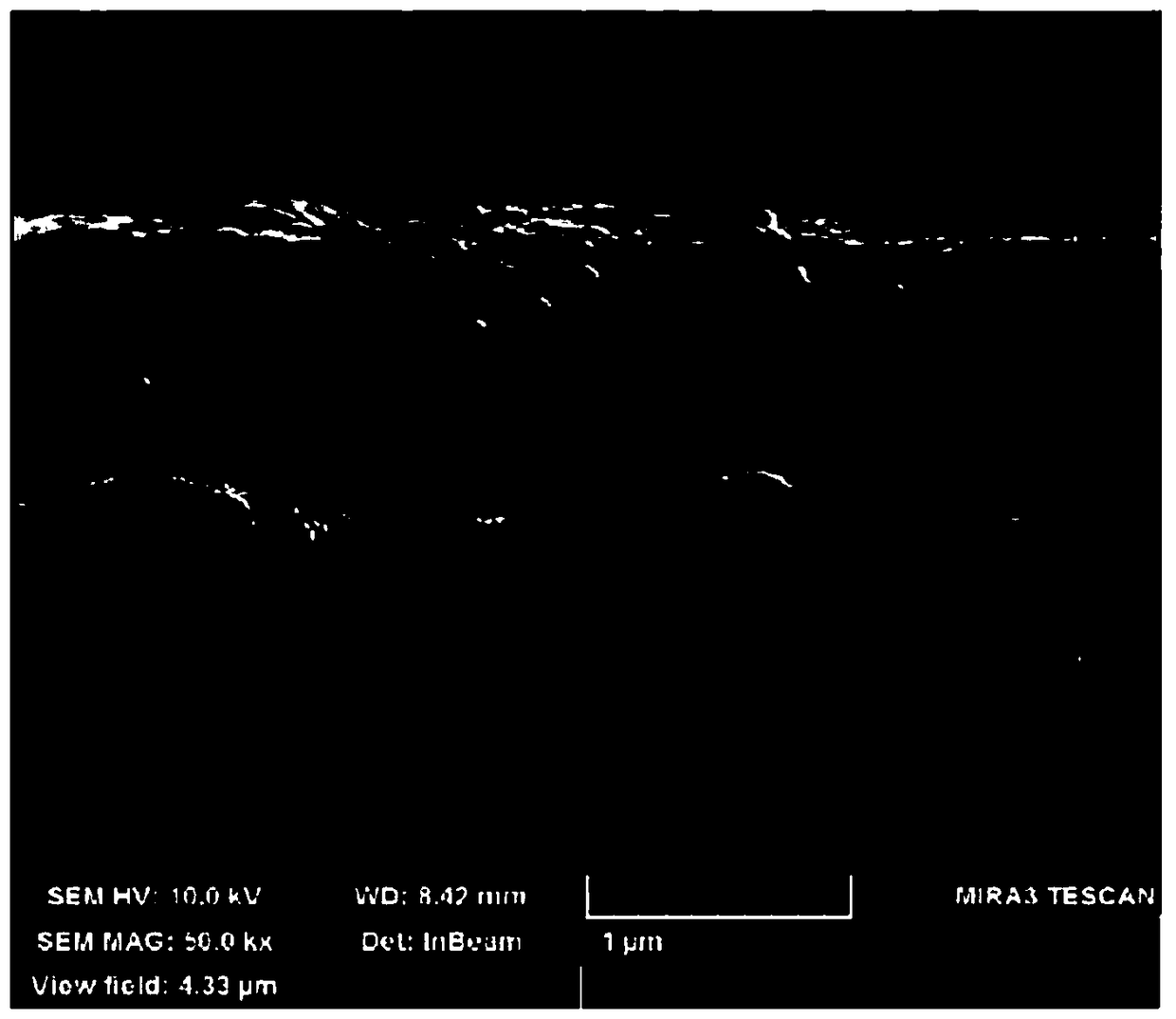

[0082] The preparation method of the silver wire includes the following steps: dissolving silver salt, potassium bromide and polyvinylpyrrolidone (PVP for short) in an organic solvent, and reacting at 170° C. under inert gas protection conditions to prepare the silver wire.

[0083] Further, the silver wire is dissolved in an organic solvent with low boiling point and low carbon content to form a silver wire ink, which is coated on the aluminum-doped zinc oxide precursor film. The concentration of the dissolved silver wire in the organic solvent is 0.2-1.0 mL / g.

[0084] The organic solvent with a low boiling point and low carbon content is an organic solvent with 1 to 4 carbons and a low boiling point. The low carbon content is conducive to the fusion of silver wire and aluminum-doped zinc oxide, and the low boiling point is easy to volatilize and remove.

[0085] The silver line ink spin coating can also be tempered, the tempering temperature is 120-150°C, preferably 150°C, ...

Embodiment 1

[0092](1) The substrate ITO conductive glass 30×30 mm was ultrasonically cleaned with alkaline cleaning solution, acetone, isopropanol and high-purity deionized water for 15 minutes, blown dry with nitrogen, and then cleaned the surface of the substrate with ozone using a UV cleaning machine 10 minutes, then put it into a vacuum drying oven for subsequent use;

[0093] (2) Preparation of copper-zinc-tin-sulfur absorption layer: Weigh copper acetate, zinc acetate, tin chloride and thiourea, dissolve them in ethylene glycol methyl ether solvent, and react at 45°C for 30 minutes to obtain the copper-zinc-tin-sulfur precursor sol , the concentration ratio of metal ions in the copper-zinc-tin-sulfur precursor sol is Cu / (Zn+Sn)=0.8, Zn / Sn=1.2, and the method of spin coating deposition is used to deposit the copper-zinc-tin-sulfur precursor sol on the surface of ITO conductive glass , to obtain copper-zinc-tin-sulfur precursor films. Then sulfidation and tempering treatment at 350°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com