A kind of preparation method of high temperature resistant strong alkali defoamer

A technology of high temperature resistance and alkali elimination, which is applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problems of losing the bubble-stimulating effect, achieve increased dispersion, long-lasting defoaming performance, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

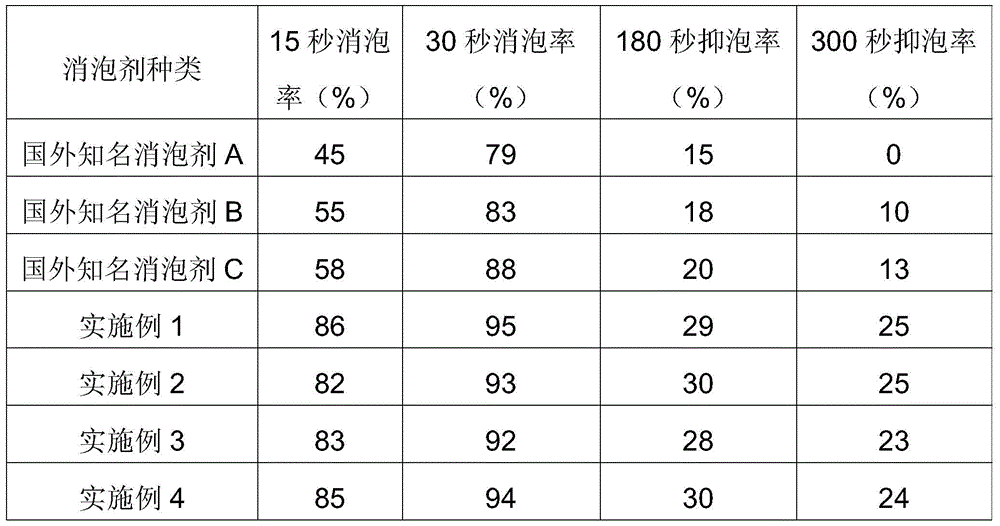

Examples

preparation example Construction

[0025] The preparation method of high temperature resistant strong alkali defoamer of the present invention comprises the following steps:

[0026] 1) Synthesis of network structure polymer: Vinyl MQ silicone resin (vinyl content is 2% to 5%, MQ ratio is 0.6 to 1.0) and hydrogen-containing silicone oil (hydrogen content is 0.1% to 0.36%, viscosity 200~500cst) mixed with mass ratio (1:1)~(1:1.3) into the reaction kettle, heated while stirring in nitrogen atmosphere, when the temperature rose to 100℃, slowly added dropwise chloroplatinic acid catalyst (the amount of chloroplatinic acid catalyst added is 0.1% to 0.3% of the total mass of MQ silicone resin and hydrogen-containing silicone oil) for reaction, and kept at 110°C to 130°C for 2 to 4 hours to obtain a viscous network Shaped polymers;

[0027] 2) Preparation of high temperature resistant strong alkali silicone paste: 20% to 50% of the network structure polymer prepared in step 1) and 5% to 10% of white carbon black (pow...

Embodiment 1

[0032] Add 150 grams of vinyl MQ silicone resin with a vinyl content of 4% and an MQ ratio of 0.8, 200 grams of hydrogen-containing silicone oil with a hydrogen content of 0.1% and a viscosity of 200 cst in a 1L reactor, and heat to 100°C. In a nitrogen atmosphere, 0.35 g of chloroplatinic acid catalyst was slowly added dropwise, and the temperature of the reaction system was slowly raised to 120° C.; at this temperature, a viscous liquid was obtained after 3 hours of reaction, which was a network structure polymer.

[0033] Then add the above-mentioned 445 grams of network structure polymer, 50 grams of white carbon black with a specific surface area of 270 and a hydrophobicity of 35, 300 grams of simethicone oil with a viscosity of 60000CST and dimethyl silicone oil with a viscosity of 500CST in the reactor. 200 grams of silicone oil, 5 grams of sodium hydroxide catalyst, heated to 140 ° C, and kept at 140 ° C for 5 hours to obtain a viscous mixture that is silicone paste. ...

Embodiment 2

[0036] Add 150 grams of vinyl MQ silicone resin with a vinyl content of 2% and an MQ ratio of 1.0, 150 grams of hydrogen-containing silicone oil with a hydrogen content of 0.15% and a viscosity of 300 cst in a 1L reactor, and heat to 100°C. In a nitrogen atmosphere, 0.60 g of chloroplatinic acid catalyst was slowly added dropwise, and the temperature of the reaction system was slowly raised to 110° C.; at this temperature, a viscous liquid was obtained after the reaction was kept for 4 hours, which was a network structure polymer.

[0037] Then add 200 grams of the above-mentioned network structure polymer, 100 grams of white carbon black with a specific surface area of 200 and a hydrophobicity of 50, 440 grams of simethicone oil with a viscosity of 10000CST and dimethyl silicone oil with a viscosity of 2000CST in the reactor. 250 grams of silicone oil, 10 grams of sodium hydroxide catalyst, heated to 135 ° C, and kept at 135 ° C for 3 hours to obtain a viscous mixture that i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| hydrophobicity | aaaaa | aaaaa |

| hydrophobicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com