Tree-shaped rubrene crystal thin film preparation method adopting high boiling point solvent to carry out regulation and control

A high-boiling-point solvent and thin-film preparation technology, which is applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problems of poor film quality, complicated process, and high cost, and achieve the effect of improving high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

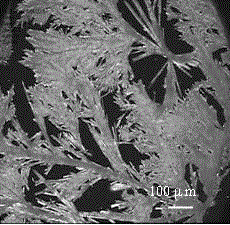

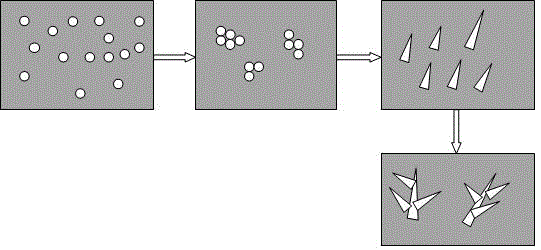

[0009] like figure 1 As shown, rubrene molecules grow into the final dendritic morphology.

[0010] The specific implementation process: the substrate is made of Si base and SiO with a surface thickness of 300nm 2 Insulation layer composition; the substrate is cleaned in the order of acetone, ethanol, and distilled water, and placed in an oven at 60°C for 20 minutes; for the configuration of rubrene solution 1, take rubrene 1mg, chloroform 0.5ml, DMF0. 3ml (hereinafter referred to as solution 1), with a volume ratio of 37.5%, was sequentially added to a 5ml reagent bottle, and then ultrasonically vibrated at room temperature with an ultrasonic intensity of 60% for 10 minutes; the substrate was taken out of the oven and placed On the model HP-127 digital display temperature precision electric heating plate, the temperature is set at 60°C; take 100μl-120μl solution from solution 1 and drop-coat it on the middle part of the substrate, rubrene molecules start from the dispersed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com