Methanol decomposition heating catalyst and preparation method thereof

A methanol decomposition and catalyst technology, which is applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of loss of use value of catalyst materials, poor durability of catalysts, and reduced service life of catalysts, and achieve higher cost of improvement. , The effect of improving durability and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

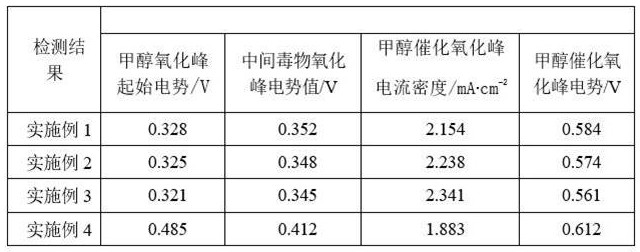

Embodiment 1

[0033] Take 0.5mol / L zirconium oxychloride solution and heat it in a water bath at 100°C, adjust the pH to 2.0 with mass fraction 0.05mol / L nitric acid, keep warm and reflux for 240h, centrifuge and collect the lower precipitate, wash with deionized water until After the washing solution is neutral, dry it at 100°C to constant weight, collect the dried particles and place them at 400°C for calcination for 3 hours to obtain the calcined matrix zirconia particles; take the zirconia particles and mass ratio 1:10, Soak it in a 1% nickel nitrate solution by mass fraction, stir and mix it and let it stand for 3 hours, dry the soaked zirconia particles at 100°C, then heat-preserve and calcinate it at 400°C for 3 hours, let it stand and cool to room temperature, crush and grind Pass through a 500-mesh sieve to obtain salt additive granules;

[0034] In terms of parts by weight, weigh 12 parts of water, 3 parts of salt additive particles, 1 part of cerium nitrate solution, 1 part of zirc...

Embodiment 2

[0038] Take 0.6mol / L zirconium oxychloride solution and heat it in a water bath at 105°C, adjust the pH to 2.0 with mass fraction 0.05mol / L nitric acid, keep warm and reflux for 245h, centrifuge and collect the lower precipitate, wash with deionized water until After the washing solution becomes neutral, dry it at 105°C to constant weight, collect the dried particles and place them at 450°C for 4 hours of heat preservation and calcination to obtain calcined matrix zirconia particles; take zirconia particles and mix them in a mass ratio of 1:10 Soak it in 1% iron nitrate solution by mass fraction, stir and mix it and let it stand for 4 hours, dry the soaked zirconia particles at 105°C, then heat-preserve and calcinate at 425°C for 4 hours, let it stand and cool to room temperature, crush and grind Pass through a 500-mesh sieve to obtain salt additive granules;

[0039] In terms of parts by weight, weigh 19 parts of water, 4 parts of salt additive particles, 1 part of cerium nit...

Embodiment 3

[0043] Take 0.8mol / L zirconium oxychloride solution and heat it in a water bath at 110°C, adjust the pH to 2.0 with mass fraction 0.05mol / L nitric acid, keep warm and reflux for 250h, centrifuge and collect the lower precipitate, wash with deionized water until After the washing solution becomes neutral, dry it at 110°C until it reaches a constant weight, collect the dried particles and place them at 500°C for calcination for 5 hours to obtain the calcined matrix zirconia particles; take the zirconia particles and mass ratio 1:10, Soak it in a 1% copper nitrate solution, stir and mix it and let it stand for 5 hours, dry the soaked zirconia particles at 110°C, then heat-preserve and calcinate at 450°C for 5 hours, let it stand and cool to room temperature, crush and grind Pass through a 500-mesh sieve to obtain salt additive granules;

[0044] In parts by weight, weigh 25 parts of water, 6 parts of salt additive particles, 2 parts of cerium nitrate solution, 3 parts of zirconiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com