Thermoelectricity module group generation performance test platform

A thermoelectric module and test platform technology, which is applied in the direction of single semiconductor device testing, measuring electricity, measuring devices, etc., can solve the problems that are not involved in the structural design of the test system, the influence of the power generation performance of the thermoelectric module, etc., and achieve simple structure and convenient assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

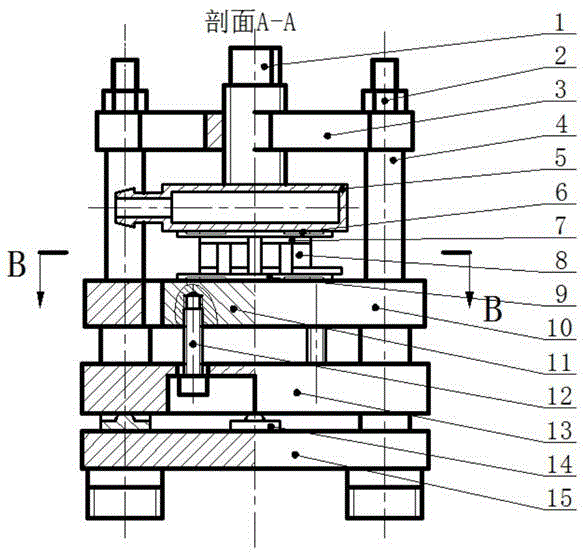

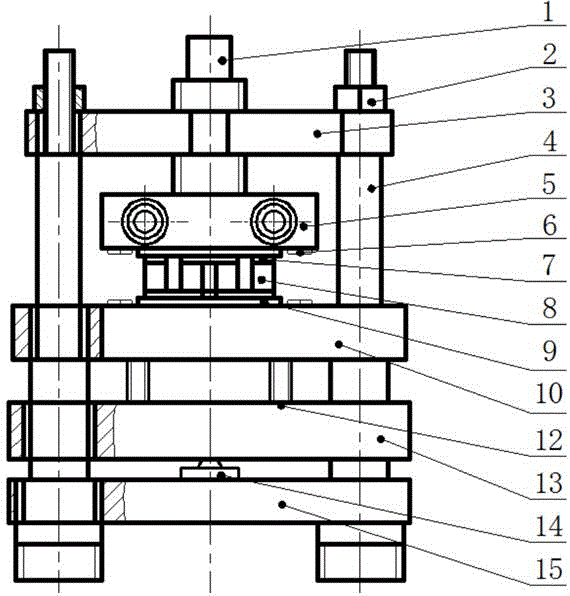

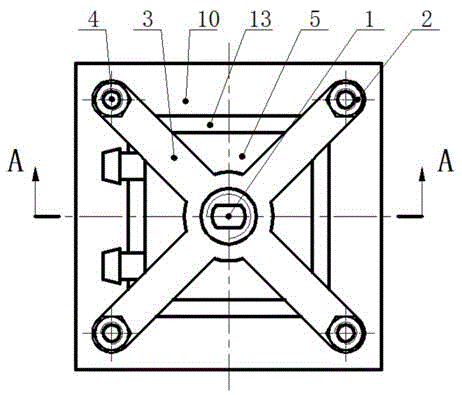

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] figure 1 , figure 2 , image 3 , Figure 4 As shown, as shown, the present invention includes a compression rod 1, a compression nut 2, a compression rod support block 3, a stepped support shaft 4, a water cooling block 5, a patch thermocouple 6, a conductive electrode 7, a thermoelectric block 8, ceramic Sheet 9, protective fence 10, electric heating platform 11, screws 12, heating platform support plate 13, pressure sensor 14 and support base plate 15. Compression module composed of pressure rod 1 and pressure rod support block 3, thermoelectric module composed of ceramic sheet 9, conductive electrode 7 and thermoelectric block 8, temperature monitoring module composed of chip thermocouple 6, and pressure sensor 14 A pressure monitoring module, a support module composed of a ladder support shaft 4 , a protective fence 10 , screws 12 , a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com