Harmless classification-free solid waste splitting decomposition device and splitting decomposition method

A solid waste and equipment technology, which is applied in the field of harmless and classification-free solid waste pyrolysis equipment, can solve the problems of high energy consumption, long downtime and large losses of equipment, and achieves the improvement of fuel utilization rate, improvement of sanitary environment, Guaranteed effect of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

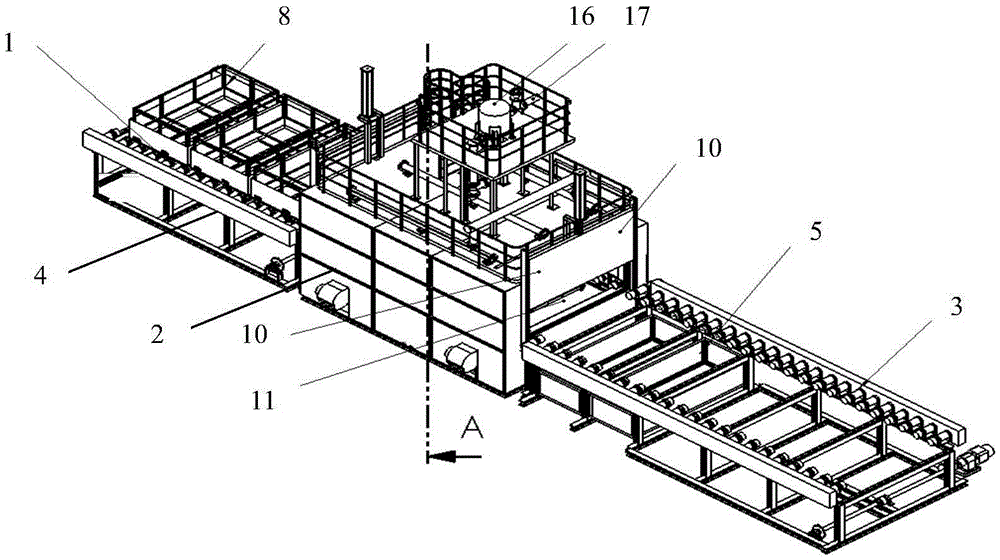

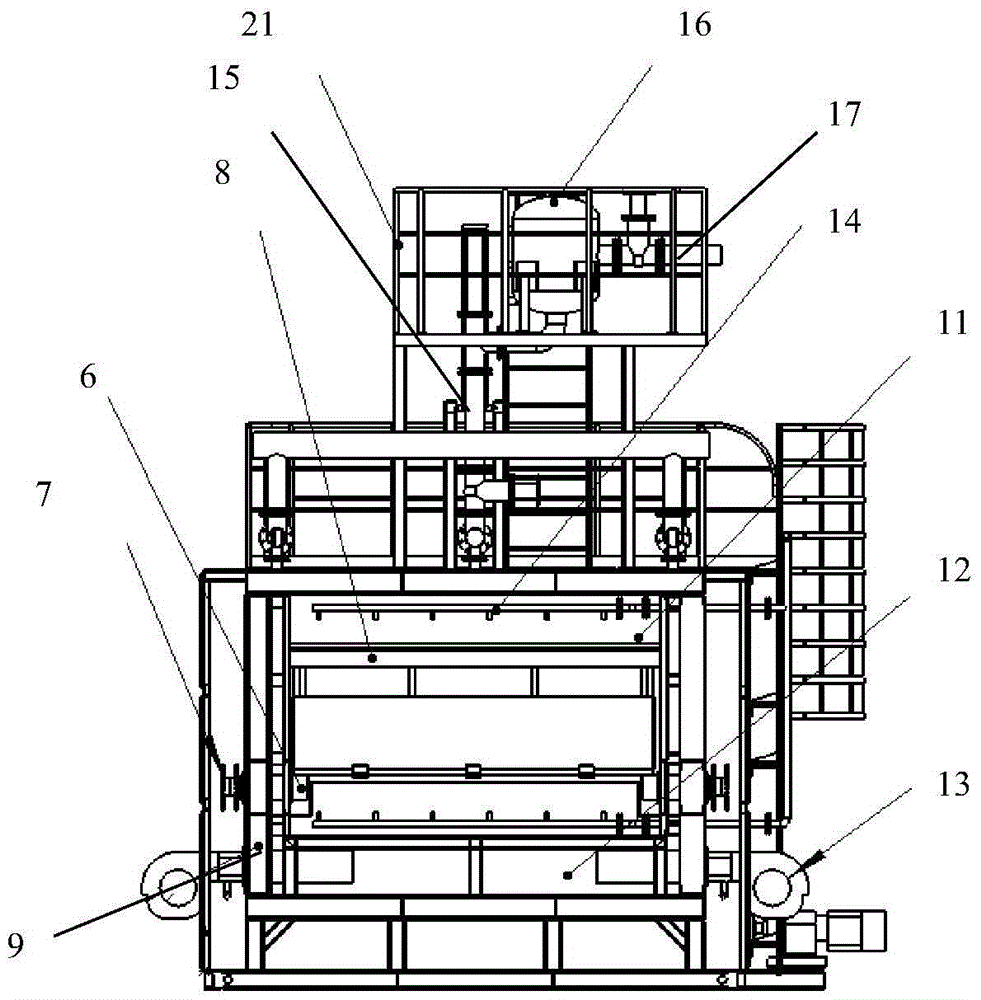

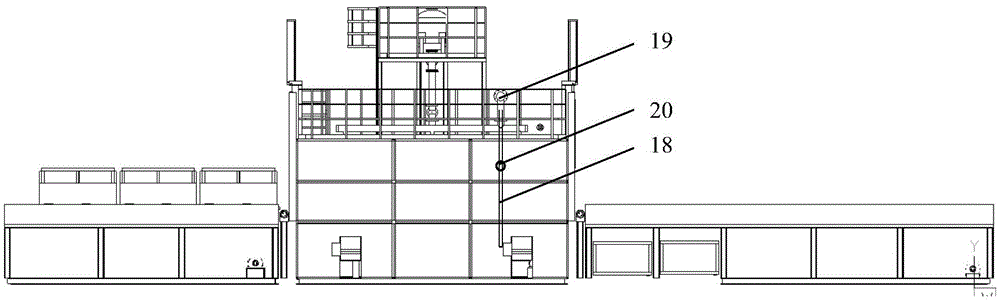

[0044] see Figure 1-Figure 3, the harmless classification-free solid waste cracking equipment 2 of the present invention includes a feeding section 1, a cracking equipment 2 and a feeding section 3 connected in sequence; the equipment includes a penetrating feeding section 1, a cracking equipment 2 and a feeding section 3 The bracket 4, the transmission roller 5 installed on both sides of the bracket 4, the transmission roller 5 and the chain 6 mesh, the transmission motor drives the sprocket 7 to rotate, and the sprocket 7 drives the chain 6 meshed with it to drive the transmission roller 5 to rotate;

[0045] A material basket 8 is placed on the driving roller 5, solid waste is placed in the material basket 8, and the material basket 8 can move along the feeding section 1, the cracking equipment 2 and the unloading section 3;

[0046] The main body of the cracking equipment 2 is a body of furnace 9, a movable airtight door 10 is arranged on the body of furnace 9 connecting ...

Embodiment 2

[0054] The harmless classification-free solid waste pyrolysis method of this embodiment includes the following steps:

[0055] 1) The first stage: the solid waste loaded in the material basket 8 is placed in the cracking chamber of the cracking equipment 2, and the temperature is raised to 150° C., and the reaction time is xx hours;

[0056] 2) The second stage: heat up to 600°C, reaction time: xx hours; generate combustible gas, cracked gas and solid carbon powder;

[0057] 3) The third stage: discharge the oil-air mixture and solid powder after cooling.

[0058] Step 2) The resulting cracked gas is condensed through a chemical catalyst reaction to obtain a mixed oil including gasoline, diesel oil and heavy oil.

[0059] The combustible gas obtained in step 2) is recovered and introduced into the burner 13 to provide the heat source of step 1) and step 2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com