Desulphurization method of coal dust via biological oxidation

A technology of biological oxidation and pulverized coal, applied in the direction of biochemical equipment and methods, methods based on microorganisms, microorganisms, etc., can solve the problems of poor removal of organic sulfur and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

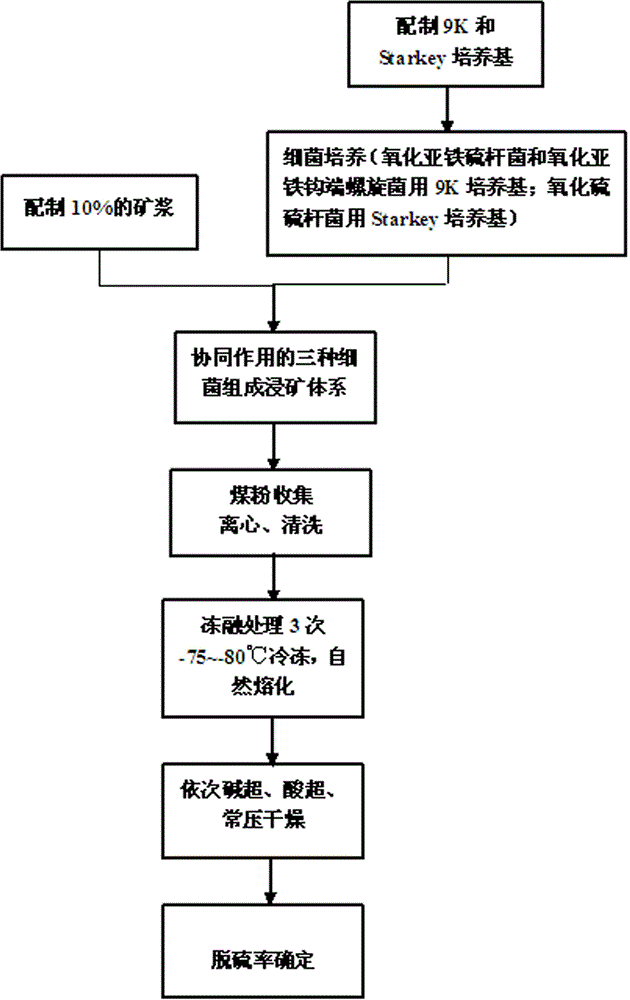

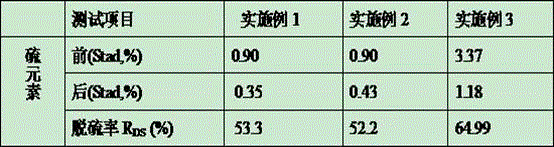

[0041] A method for biological oxidation desulfurization of pulverized coal, the sulfur content of the pulverized coal to be treated is 0.9%, carried out according to the following process steps, the process flow chart is as follows figure 1 Shown:

[0042] (1) Prepare 9K and Starkey medium:

[0043] Add (NH 4 ) 2 SO 4 , K 2 HPO 4 , MgSO 4 ·7H 2 O, Ca(NO 3 ) 2 , KCl, after all dissolved, adjust the pH to 2.0, sterilize at 121°C for 20min, add filter-sterilized FeSO after sterilization 4 ·7H 2 O, where (NH 4 ) 2 SO 4 , K 2 HPO 4 , MgSO 4 ·7H 2 O, Ca(NO 3 ) 2 and FeSO 4 ·7H 2 The concentration of O was 3g / L, 0.5g / L, 0.5g / L, 0.01g / L, 10g / L, 0.01g / L to obtain 9K medium;

[0044] Add (NH 4 ) 2 SO 4 , K 2 HPO 4 , MgSO 4 ·7H 2 O, CaCl 2 , sulfur powder, adjust the pH to 2.0 after fully dissolved, sterilize at 121°C for 20min, add filter-sterilized FeSO after sterilization 4 ·7H 2 O, where (NH 4 ) 2 SO 4 , K 2 HPO 4 , MgSO 4 ·7H 2 O, CaCl 2 , s...

Embodiment 2

[0057] A method for biological oxidative desulfurization of pulverized coal. The sulfur content of pulverized coal to be treated is also 0.9%. In the process steps, the medium preparation, the bacterial strain cultivation of ore leaching bacteria, the preparation of ore pulp, the bacterial inoculation amount of the ore leaching system, The ore leaching process, coal dust collection method, freezing-thawing, acid ultrafiltration, alkali ultrafiltration and the drying process before the sulfur content measurement are all the same as in Example 1.

[0058] Measurement of desulfurization rate of pulverized coal: The content of sulfur element in pulverized coal was measured by infrared sulfur detector to be 0.43%, and the desulfurization rate reached 64.98%.

Embodiment 3

[0060] A method for biological oxidative desulfurization of pulverized coal. The sulfur content of the pulverized coal to be treated is as high as 3.37%. In the process steps, the preparation of the medium, the cultivation of bacteria for ore leaching, the preparation of ore pulp, the amount of bacterial inoculum in the ore leaching system, and the leaching The drying process before the mine process, coal dust collection method, freezing-thawing, acid ultra, alkali ultra and sulfur content determination is all the same as in Example 1.

[0061] Measurement of desulfurization rate of pulverized coal: The content of sulfur element in pulverized coal was measured by an infrared sulfur detector to be 1.18%, and the desulfurization rate reached 64.99%. Due to the high content of sulfur in high-sulfur coal, the removal rate of sulfur is relatively high.

[0062] Table 1

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com