Preparation method and application of organic modified silica sol

An organic modifier and silica sol technology, which is applied in the treatment of dyed organosilicon compounds, chemical instruments and methods, dyed low-molecular-weight organic compounds, etc. The appearance of the sol is clear and transparent, the film-forming property is not affected, and the effect of good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

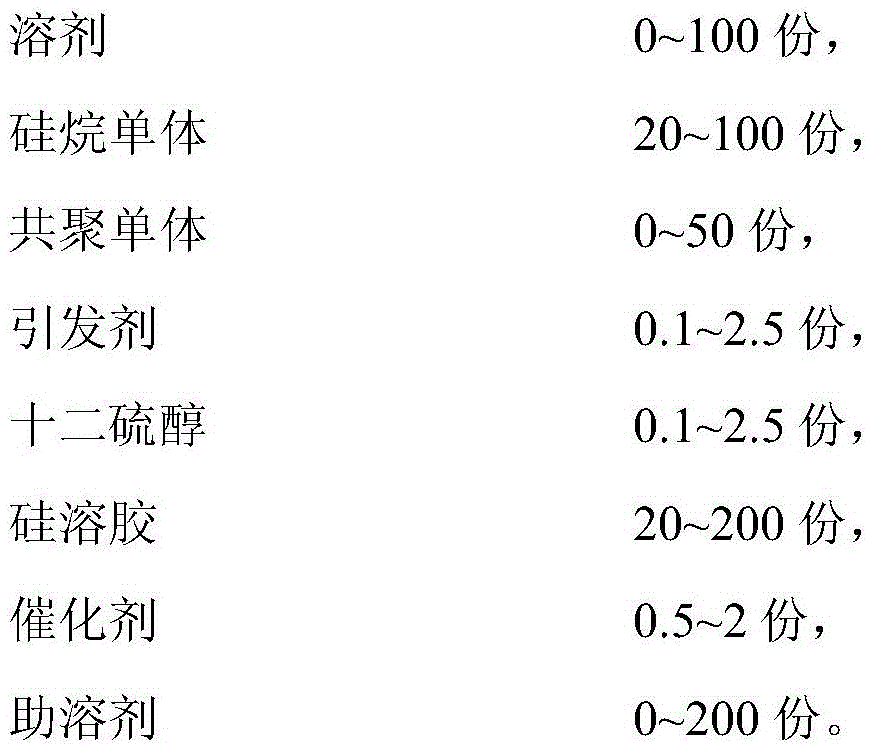

Method used

Image

Examples

Embodiment 1

[0028] 1). Preparation of organic modifier

[0029] First raise the temperature of 20 parts by weight of isopropanol to 80°C, and then dropwise add 20 parts by weight of γ-(methacryloyloxy)propyltrimethoxysilane, 10 parts by weight of polyethylene glycol methyl 1 / 3 of the weight of the mixed solution composed of acrylate, 20 parts by weight of styrene, 0.5 parts by weight of AIBN, and 0.5 parts by weight of dodecyl mercaptan, add the remaining mixed solution dropwise after 30 minutes, and keep the temperature after the dropwise addition After 3 hours, the temperature was lowered, filtered, and the solvent was removed under reduced pressure to obtain the silica sol organic modifier 1.

[0030] 2).Modification of silica sol

[0031] Get 50 parts by weight of acidic silica sol (average particle diameter 20nm, solid content is 30%), add the catalyst formic acid of 1 part by weight, and the ethanol of 50 parts by weight, then add dropwise the organic modifier 1 of 20 parts by weig...

Embodiment 2

[0033] 1). Preparation of organic modifier

[0034] First raise the temperature of 30 parts by weight of isopropanol to 60°C, and then dropwise add 30 parts by weight of γ-(methacryloyloxy)propyl triethoxysilane, 10 parts by weight of polyethylene glycol 1 / 3 of the weight of the mixed solution composed of methacrylate, 0.3 parts by weight of AIBN, and 2.5 parts by weight of dodecanethiol, and then add the remaining mixed solution dropwise after 15 minutes, keep the temperature for 8 hours after the dropwise addition, and finally cool down , filtered, and the solvent was removed under reduced pressure to obtain silica sol organic modifier 2.

[0035] 2).Modification of silica sol

[0036] Get 30 parts by weight of alkaline silica sol (average particle diameter 20nm, solid content is 30%), add 0.5 parts by weight of catalyst acetic acid, and 30 parts by weight of isopropanol, then dropwise add 100 parts by weight of organic modifier 2. After modification at 30° C. for 5 hours,...

Embodiment 3

[0038] 1). Preparation of organic modifier

[0039] First raise the temperature of 40 parts by weight of isopropanol to 70°C, and then add 40 parts by weight of γ-(methacryloyloxy)propyltrimethoxysilane and 50 parts by weight of N-vinylpyrrolidone dropwise at this temperature. , 1 / 3 of the mixed solution weight that the AIBN of 0.1 weight part, the dodecyl mercaptan of 2 weight parts form, then add dropwise remaining mixed solution after 45min, after dropping, keep warm for 7h again, finally through cooling, filter, and The solvent was removed under reduced pressure to obtain silica sol organic modifier 3.

[0040] 2).Modification of silica sol

[0041] Get 20 parts by weight of neutral silica sol (average particle diameter 20nm, solid content is 30%), add 1.5 parts by weight of catalyst industrial hydrochloric acid, and 20 parts by weight of n-butanol, then dropwise add 10 parts by weight of organic modified Agent 3 was modified at 40° C. for 4 hours, and filtered to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com