High-elasticity environmentally-friendly flame-retardant rubber material

A technology of flame-retardant rubber and high elasticity, which is applied in the field of high-elastic and environmentally friendly flame-retardant rubber materials. It can solve the problems of poor mechanical properties of materials, achieve good aging resistance, increase dispersion performance, improve stretch resistance and elastic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

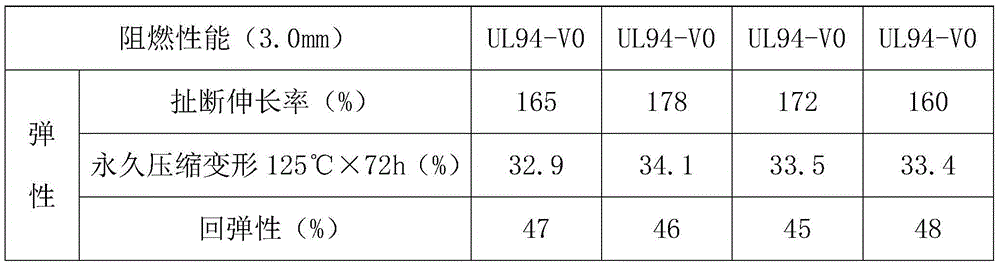

Embodiment 1

[0018] A kind of highly elastic environment-friendly flame-retardant rubber material proposed by the present invention, its raw material comprises by weight: 75 parts of hydrogenated nitrile rubber, 30 parts of EPDM rubber, 35 parts of styrene-butadiene rubber, 18 parts of vinyl chloride thermoplastic elastomer , 14 parts of ABS resin, 4 parts of di-tert-butyl peroxide DTBP, 1.5 parts of sulfur, 3 parts of divinylbenzene, 2 parts of accelerator DM, 45 parts of modified clay, 30 parts of smoky rubber, 10 parts of magnesium oxide, hard 1 part of fatty acid, 18 parts of modified flame retardant, 5 parts of polyphenylene ether, 10 parts of diisononyl phthalate DINP, 1 part of anti-aging agent D-501, 3 parts of anti-aging agent SP, 10 parts of epoxy soybean oil;

[0019] The preparation method of the modified flame retardant includes: adding 100 parts of intumescent flame retardant IFR into absolute ethanol in parts by weight, and ultrasonically dispersing for 0.2 hours to obtain a ...

Embodiment 2

[0023] A kind of highly elastic environment-friendly flame-retardant rubber material proposed by the present invention, its raw material comprises by weight: 80 parts of hydrogenated nitrile rubber, 25 parts of EPDM rubber, 40 parts of styrene-butadiene rubber, 12 parts of vinyl chloride thermoplastic elastomer , 20 parts of ABS resin, 2 parts of di-tert-butyl peroxide DTBP, 2.5 parts of sulfur, 1 part of divinylbenzene, 4 parts of accelerator DM, 40 parts of modified clay, 38 parts of smoky rubber, 5 parts of magnesium oxide, hard 3 parts of fatty acid, 10 parts of modified flame retardant, 10 parts of polyphenylene ether, 6 parts of diisononyl phthalate DINP, 2 parts of anti-aging agent D-502, 1 part of anti-aging agent SP, 15 parts of epoxy soybean oil;

[0024] The preparation method of the modified flame retardant comprises: adding 100 parts of intumescent flame retardant IFR into absolute ethanol in parts by weight, and ultrasonically dispersing for 0.5 hours to obtain a ...

Embodiment 3

[0028] A kind of highly elastic environment-friendly flame-retardant rubber material proposed by the present invention, its raw material comprises by weight: 76 parts of hydrogenated nitrile rubber, 28 parts of EPDM rubber, 37 parts of styrene-butadiene rubber, 16 parts of vinyl chloride thermoplastic elastomer , 16 parts of ABS resin, 3 parts of di-tert-butyl peroxide DTBP, 1.8 parts of sulfur, 2 parts of divinylbenzene, 3 parts of accelerator DM, 44 parts of modified clay, 32 parts of smoky rubber, 8 parts of magnesium oxide, hard 1 part of fatty acid, 16 parts of modified flame retardant, 7 parts of polyphenylene ether, 9 parts of diisononyl phthalate DINP, 1 part of anti-aging agent D-501, 3 parts of anti-aging agent SP, 12 parts of epoxy soybean oil;

[0029] The preparation method of the modified flame retardant comprises: adding 100 parts of intumescent flame retardant IFR into absolute ethanol by weight, and ultrasonically dispersing for 0.3 hours to obtain a suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com