Forming method of flame-retarding insulating riser

A technology of flame retardant heat preservation and molding method, which can be used in casting molding equipment, molds, cores, etc., and can solve problems such as poor heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

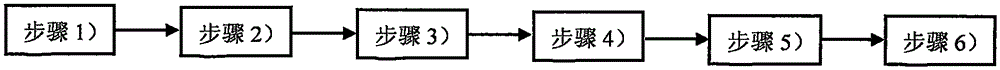

[0030] see figure 1, a method for forming a flame-retardant thermal insulation riser, which comprises the following steps:

[0031] 1) According to the shape requirements of the riser, the inner mold, outer mold and filler template are made: the top of the inner mold is closed, and after closing with the outer mold, a cylindrical cavity is formed. The height and the outer diameter are the same; the size of the filler template is between the size of the inner mold and the outer mold, the top of the filler template is open, and the top of the outer mold is provided with a circular sand injection port;

[0032] 2) Preparation of thermal insulation filler with flame retardant effect:

[0033] a. Weigh 20-30 parts of diatomite, 5-10 parts of polyphenylene balls, 12-15 parts of magnesia powder, 15-20 parts of quartz sand, 10-15 parts of Aluminum silicate fiber, 15-20 parts of modified magnesium aluminum alloy powder, 8-10 parts of iron oxide powder, 2-5 parts of sodium nitrate, 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com