Medicinal toothpaste containing nutgall ethyl acetate extract and production method thereof

A technology of seed ethyl acetate and production method, which is applied in the fields of pharmaceutical formula, dentistry, medical science, etc., can solve the problems of being easily oxidized, precipitated, etc., and achieve the effect of increasing service life and frequency, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

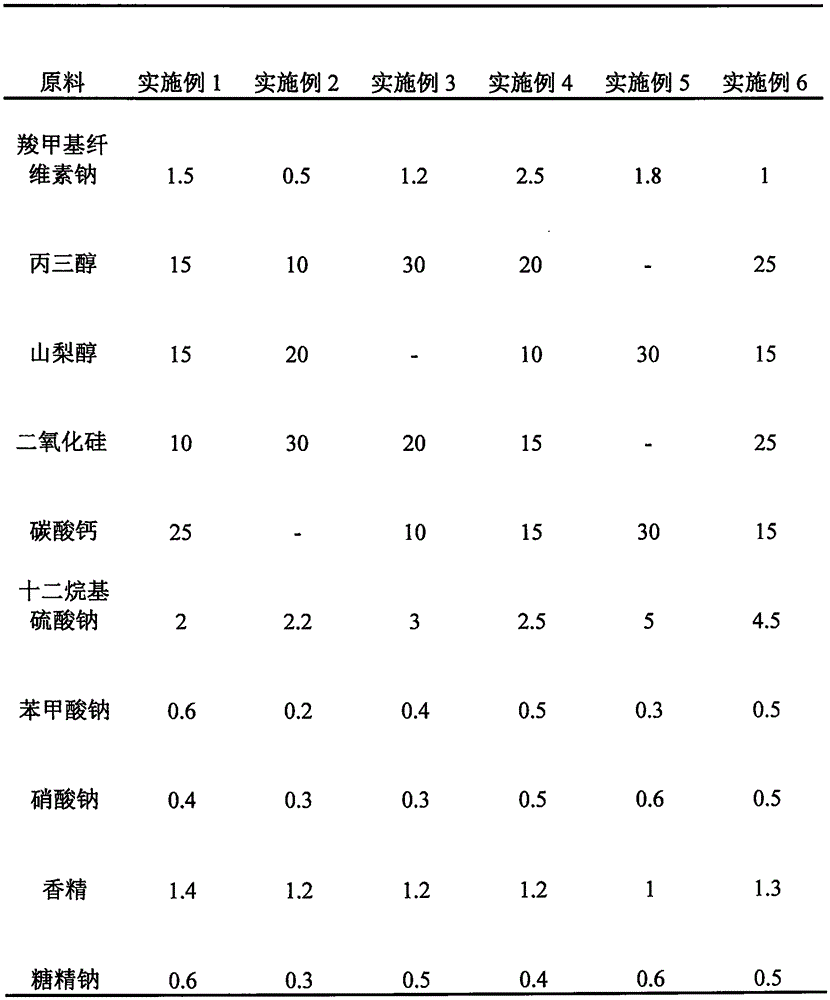

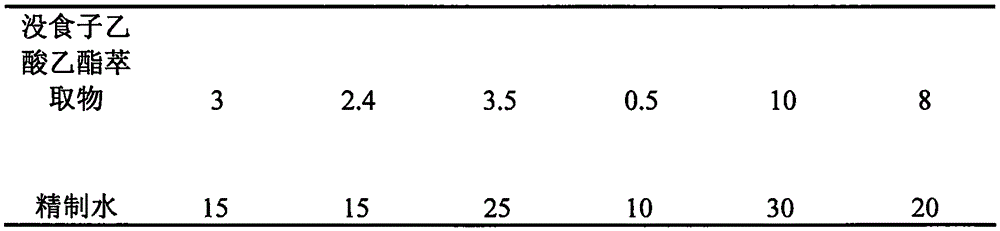

Embodiment 1

[0027] Step 1: Soak the galls in petroleum ether and percolate, recover the residue, evaporate the petroleum ether in the residue, and then extract it with deionized water under reflux. After the extract is concentrated, it is extracted with ethyl acetate of the same volume as the concentrated solution, and the upper layer is collected The clear liquid was evaporated to dryness to obtain the ethyl acetate extract.

[0028] The second step: take 10 parts of silicon dioxide, 25 parts of calcium carbonate, 2 parts of sodium lauryl sulfate, 15 parts of glycerin, 15 parts of sorbitol, 1.5 parts of sodium carboxymethyl cellulose, 0.6 parts of sodium saccharin, flavor 1.4 spares.

[0029] The third step: making ointment, first disperse 1.5 parts of sodium carboxymethylcellulose evenly in 15 parts of glycerol and 15 parts of sorbitol, and then dissolve 0.6 parts of sodium saccharin and 0.4 parts of sodium nitrate in 15 parts of purified water part, mix the two solutions under stirrin...

Embodiment 2

[0031] Step 1: Soak the galls in petroleum ether and percolate, recover the residue, evaporate the petroleum ether in the residue, and then extract it with deionized water under reflux. After the extract is concentrated, it is extracted with ethyl acetate of the same volume as the concentrated solution, and the upper layer is collected The clear liquid was evaporated to dryness to obtain the ethyl acetate extract.

[0032] Step 2: Take 30 parts of silicon dioxide, 2.2 parts of sodium lauryl sulfate, 10 parts of glycerin, 20 parts of sorbitol, 0.5 parts of sodium carboxymethylcellulose, 0.3 parts of sodium saccharin, and 1.2 parts of essence for later use.

[0033] The third step: making ointment, first disperse 0.5 parts of sodium carboxymethylcellulose in 10 parts of glycerol and 20 parts of sorbitol, and then dissolve 0.3 parts of sodium saccharin and 0.3 parts of sodium nitrate in 15 parts of purified water , mix the two solutions under stirring to make it swell into a unif...

Embodiment 3

[0035] Step 1: Soak the galls in petroleum ether and percolate, recover the residue, evaporate the petroleum ether in the residue, and then extract it with deionized water under reflux. After the extract is concentrated, it is extracted with ethyl acetate of the same volume as the concentrated solution, and the upper layer is collected The clear liquid was evaporated to dryness to obtain the ethyl acetate extract.

[0036] Step 2: Take 20 parts of silicon dioxide, 10 parts of calcium carbonate, 3 parts of sodium lauryl sulfate, 30 parts of glycerin, 1.2 parts of sodium carboxymethyl cellulose, 0.5 parts of sodium saccharin, and 1.2 parts of essence for later use.

[0037] The third step: making ointment, first disperse 1.2 parts of sodium carboxymethylcellulose evenly in 30 parts of glycerol, and then dissolve 0.5 parts of sodium saccharin and 0.3 parts of sodium nitrate in 25 parts of purified water, and stir Mix the two solutions to make it swell into a uniform colloid, also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com