Functional feed and mixed batch for alleviating heat stress of breeding boars

A functional heat stress technology, applied in animal feed, animal feed, application, etc., can solve the problem that the heat stress resistance of breeding boars is not obvious, so as to improve appetite and weight gain rate, and relieve heat stress The effect of stimulating and increasing feed intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

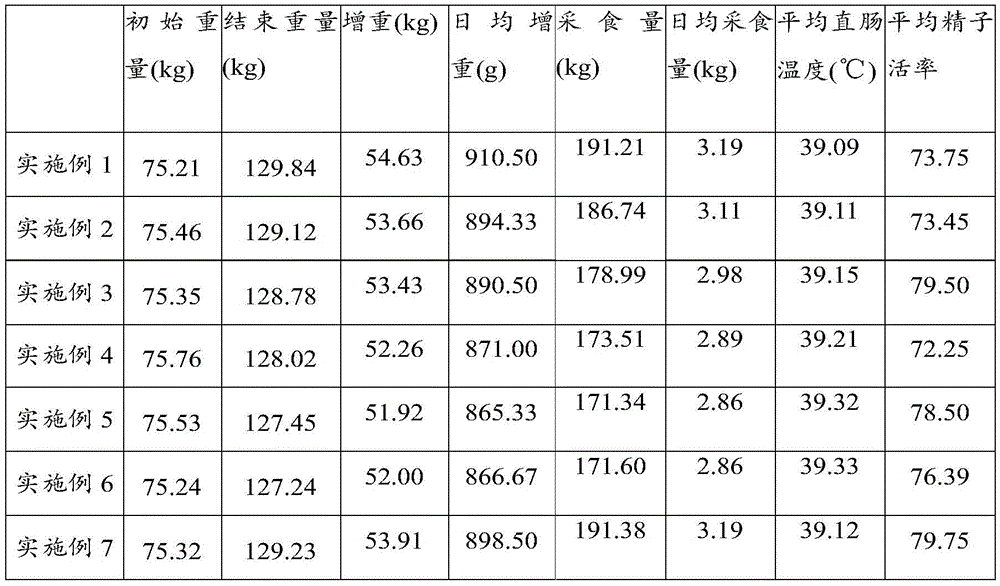

Image

Examples

Embodiment 1

[0028] Weigh the following raw materials to prepare astragalus polysaccharide compound extract: 20 parts of astragalus, 20 parts of Codonopsis, 20 parts of Bupleurum, 10 parts of tangerine peel, 20 parts of herb, 5 parts of honeysuckle, 10 parts of jujube seed, 5 parts of Acanthopanax, 10 parts of Schisandra .

[0029] Wash astragalus, codonopsis, bupleurum, tangerine peel, herb, honeysuckle, jujube seed, eleuthero and schisandra with water and put them into a decoction container, add water to the decoction container for the first boiling, and then put The first boiling filtrate is taken out, water is added to the boiling container again and the second boiling is carried out, then the second boiling filtrate is taken out and mixed with the first boiling filtrate to obtain the filtrate, and the filtrate is subjected to high pressure Concentrate, and finally spray-dry the concentrated filtrate to obtain the astragalus polysaccharide compound extract.

[0030] Preparation of fun...

Embodiment 2

[0034] Weigh the following raw materials to prepare astragalus polysaccharide compound extract: 20 parts of astragalus, 20 parts of Codonopsis, 20 parts of Bupleurum, 10 parts of tangerine peel, 20 parts of herb, 5 parts of honeysuckle, 10 parts of jujube seed, 5 parts of Acanthopanax, 10 parts of Schisandra .

[0035] Wash astragalus, codonopsis, bupleurum, tangerine peel, herb, honeysuckle, jujube seed, eleuthero and schisandra with water and put them into a decoction container, add water to the decoction container for the first boiling, and then put The first boiling filtrate is taken out, water is added to the boiling container again and the second boiling is carried out, then the second boiling filtrate is taken out and mixed with the first boiling filtrate to obtain the filtrate, and the filtrate is subjected to high pressure Concentrate, and finally spray-dry the concentrated filtrate to obtain the astragalus polysaccharide compound extract.

[0036] Preparation of fun...

Embodiment 3

[0040] Weigh the following raw materials to prepare astragalus polysaccharide compound extract: 20 parts of astragalus, 20 parts of Codonopsis, 20 parts of Bupleurum, 10 parts of tangerine peel, 20 parts of herb, 5 parts of honeysuckle, 10 parts of jujube seed, 5 parts of Acanthopanax, 10 parts of Schisandra .

[0041] Wash astragalus, codonopsis, bupleurum, tangerine peel, herb, honeysuckle, jujube seed, eleuthero and schisandra with water and put them into a decoction container, add water to the decoction container for the first boiling, and then put The first boiling filtrate is taken out, water is added to the boiling container again and the second boiling is carried out, then the second boiling filtrate is taken out and mixed with the first boiling filtrate to obtain the filtrate, and the filtrate is concentrated under high pressure , and finally spray-dry the concentrated filtrate to obtain the astragalus polysaccharide complex extract.

[0042] Preparation of functiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com