A portable bidirectional constant current source module

A constant current source module, portable technology, applied in the field of electronics, can solve the problems of large impact, drop, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

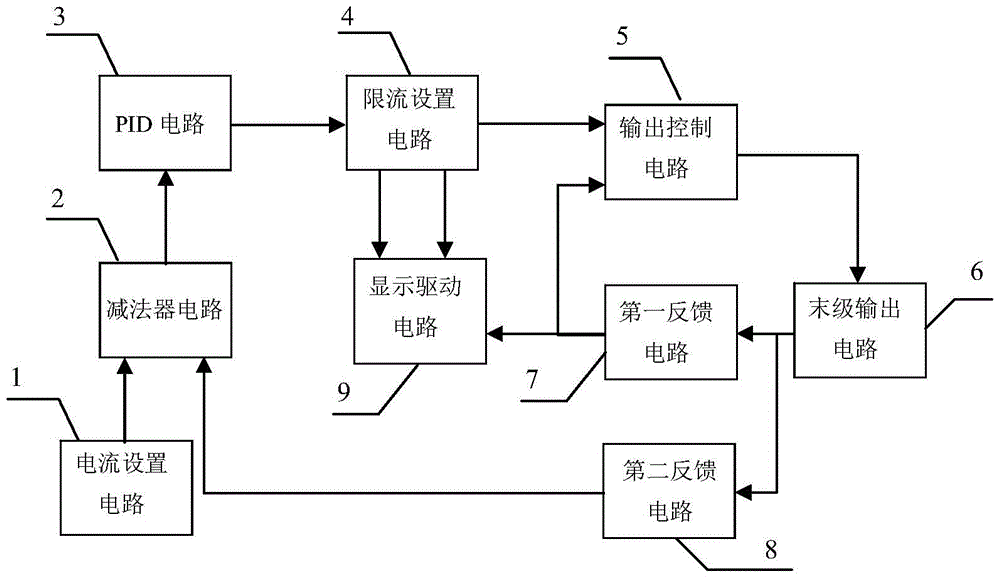

[0040] Embodiment 1 Overall structure of the present invention

[0041] to combine figure 1 The overall working principle of a bidirectional constant current source circuit of the present invention is described. A reference voltage is set through the current setting circuit 1, and the second feedback circuit 8 samples the output current and converts it into a corresponding voltage. The above two voltages are differenced in the subtractor circuit 2, and the difference is sent to the PID circuit 3 for PID Operation, the result of the operation is sent to the current limit setting circuit 4, if the result of the operation is within the current limit value range set by the current limit setting circuit 4, then the calculation result is directly output, if the result of the operation exceeds the current limit setting circuit 4 current limit value range, then output the current limit value, the output value of the current limit setting circuit 4 is sent to the control input termina...

Embodiment 2

[0042] Example 2 front panel

[0043] The structure of front panel 10 of the present invention is as Figure 12As shown, the structure includes: 9-pin D-shaped interface 101, upper limit adjustment 102, lower limit adjustment 103 and output adjustment 104; see Figure 13 , pin 1 and pin 5 of the 9-pin D-shaped interface 101 are grounded, pin 6 is connected to the power supply VCC, pin 2 is connected to the power supply VEE, pin 7 and pin 3 are respectively connected to the port CURRENT+ and port CURRENT- of the final output circuit 6, Pin 8, pin 4, and pin 9 are respectively connected to the port CURRENT_DIS, port LIMIT_L_DIS, and port LIMIT_H_DIS of the display drive circuit 9; the upper limit adjustment 102 and the lower limit adjustment 103 are respectively the potentiometer W2 and the potentiometer in the current limiting setting circuit 4 The adjustment screw of W3; the output adjustment 104 is the adjustment screw of the potentiometer W1 in the current setting circuit 1...

Embodiment 3

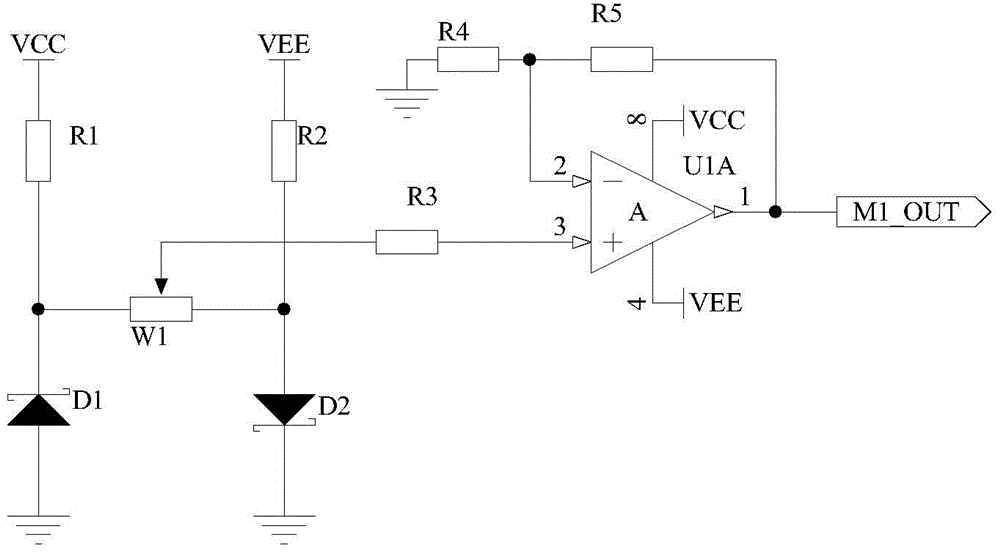

[0045] Embodiment 3 current setting circuit

[0046] The principle circuit of the current setting circuit 1 of the present invention is as figure 2 As shown, one end of the resistor R1 is connected to the power supply VCC, the other end is connected to the cathode of the Zener diode D1 and one end of the potentiometer W1, the anode of the Zener diode D1 is grounded, one end of the resistor R2 is connected to the power supply VEE, and the other end is connected to the Zener diode D2 The anode of the potentiometer W1 and the other end of the potentiometer W1, the cathode of the Zener diode D2 is grounded, the slide wire of the potentiometer W1 is connected to one end of the resistor R3, the other end of the resistor R3 is connected to the non-inverting input terminal of the operational amplifier U1A, and the reverse terminal of the operational amplifier U1A The phase input terminal is connected to one end of the resistor R4 and one end of the resistor R5, the other end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com