A kind of method for preparing propylene carbonate

A technology of propylene carbonate and propylene oxide, applied in the field of preparing propylene carbonate, can solve the problems of unavailability and difficult contact of active centers, and achieve the effects of simple and easy control, high selectivity, and improved single-pass life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

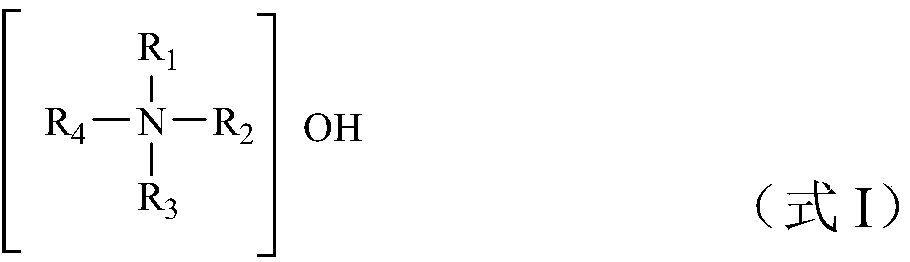

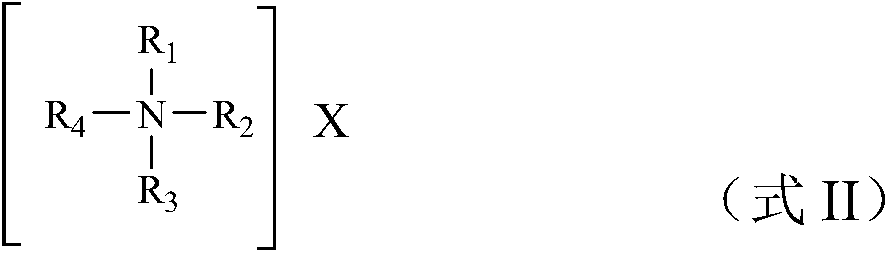

Image

Examples

Embodiment approach

[0075] According to a preferred embodiment of the present invention, the propylene oxide is prepared as follows: in the presence of methanol, propylene is contacted with hydrogen peroxide and titanium-silicon molecular sieves to separate and obtain propylene oxide.

[0076] According to the method of the present invention, the hydrogen peroxide may be hydrogen peroxide commonly used in the art in various forms. From the viewpoint of further improving safety, the method according to the present invention preferably uses hydrogen peroxide in the form of an aqueous solution. According to the method of the present invention, when the hydrogen peroxide is provided in the form of an aqueous solution, the concentration of the aqueous hydrogen peroxide solution can be a conventional concentration in the field, for example: 20-80% by weight. The aqueous solution of hydrogen peroxide whose concentration meets the above requirements can be prepared by conventional methods, and can also b...

Embodiment 1

[0104] (1) Preparation of titanium silicate molecular sieve TS-1 containing template

[0105] It is prepared according to the method described in Zeolites, 1992, Vol.12 pages 943-950 (the step of roasting is omitted), and the specific method is as follows.

[0106] At room temperature (20°C), mix 22.5 grams of tetraethyl orthosilicate with 7.0 grams of tetrapropylammonium hydroxide, add 59.8 grams of distilled water, stir and mix, then hydrolyze at normal pressure and 60°C for 1.0 hour to obtain ortho To the hydrolysis solution of tetraethyl silicate, slowly add a solution consisting of 1.1 g of tetrabutyl titanate and 5.0 g of anhydrous isopropanol under vigorous stirring, and stir the resulting mixture at 75°C for 3 hours to obtain a clear Transparent colloid, put this colloid into a stainless steel sealed reaction kettle, and place it at a constant temperature at 170°C for 3 days to obtain a mixture of crystallized products; filter the mixture, wash with water, and dry at 1...

Embodiment 2

[0123] Adopt the same method as Example 1 to prepare propylene carbonate, the difference is that in step (1), with reference to the method disclosed in the Chinese patent CN1132699C, the following method is used to prepare the hollow titanium-silicon molecular sieve HTS containing the template;

[0124] Take the template-containing molecular sieve obtained in Example 1 and roast the TS-1 molecular sieve at 550° C. for 3 hours according to the ratio of molecular sieve (gram): sulfuric acid (mol): water (mol) = 100:0.15:150, and mix evenly at 90° C. The reaction was carried out for 5.0 hours, and then filtered, washed and dried according to conventional methods to obtain acid-treated TS-1 molecular sieves. The above-mentioned acid-treated TS-1 molecular sieve is mixed uniformly according to the ratio of molecular sieve (gram): triethanolamine (mol): tetrapropyl ammonium hydroxide (mol): water (mol) = 100:0.20:0.15:180, put into The stainless steel sealed reaction kettle was plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com