Precursor and LMFP and preparation method and application thereof

A technology of precursors and iron salts, applied in the field of precursors, can solve the problems of poor rate and cycle performance, lithium manganese iron phosphate discharge capacity and low initial efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] As mentioned above, M in the precursor is a doping element, which can improve the conductivity of the material. In the present invention, as a preferred embodiment of the present invention, the precursor may not contain doping elements. At this time, its general formula is Mn x Fe 1-x C 2 o 4 2H 2 O. Preferably, 0.5≤X≤0.8, more preferably 0.6≤X≤0.8.

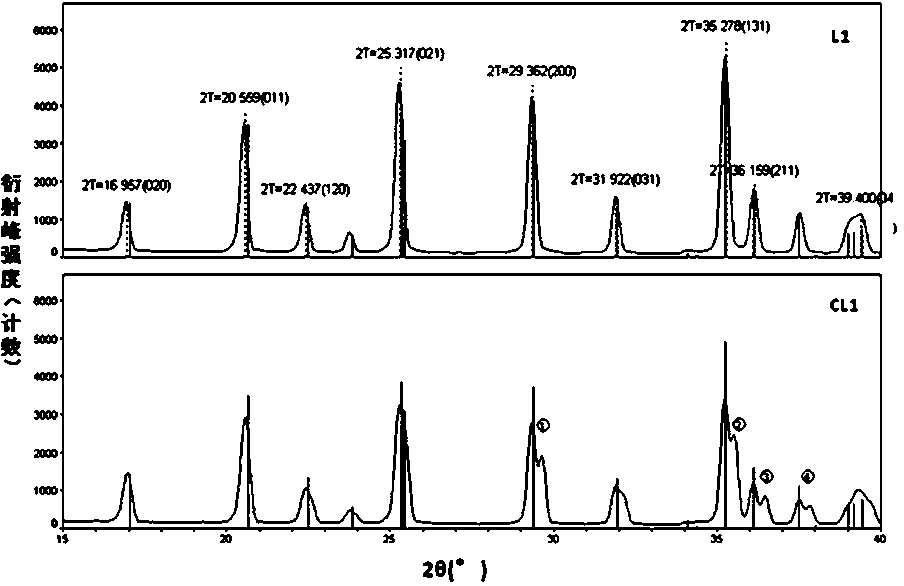

[0022] In the present invention, the precursor is a single-phase solid-solution LMFP, and the inner manganese is evenly distributed, the iron content gradually decreases from the outside to the inside, and the manganese content gradually increases accordingly, and the Mn content of the surface layer is 0.

[0023] The present invention also provides a preparation method of the above-mentioned precursor, which method comprises water-soluble divalent manganese source, water-soluble ferrous iron source, water-soluble divalent metal M salt and precipitation agent except manganese salt and iron salt mixing and reacting, a...

Embodiment 1

[0053] This example is used to illustrate the precursor and lithium manganese iron phosphate provided by the present invention and its preparation method.

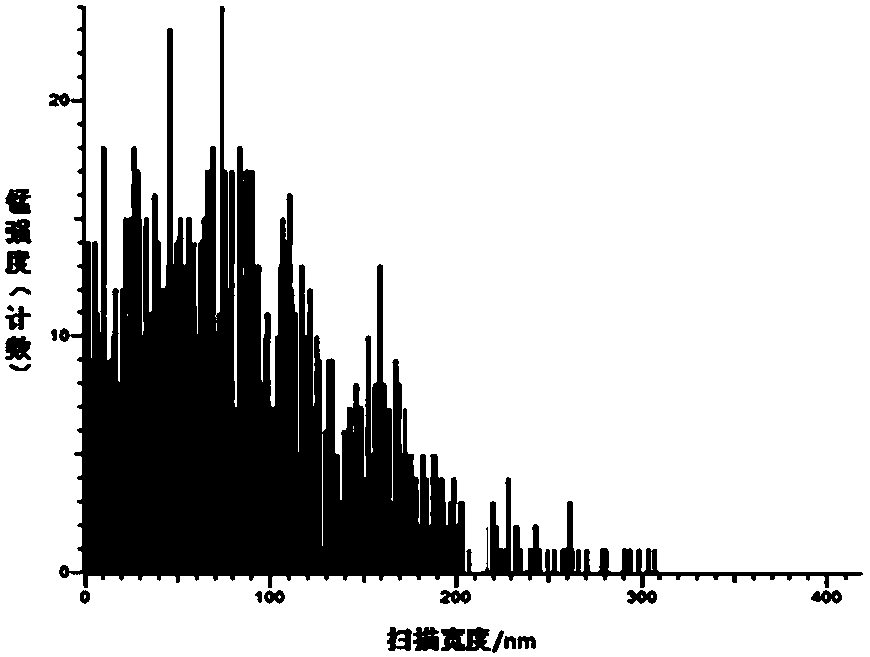

[0054] Dissolve 35.97 grams of ferrous nitrate and 200.81 grams of manganese nitrate in 5L of deionized water, dissolve 184.23 grams of potassium oxalate in 10L of deionized water, and then add ferrous nitrate and manganous nitrate to the potassium oxalate solution simultaneously and in parallel At the same time, dilute nitric acid was used to control the pH of the reaction solution to 6.5, and the reaction was stirred and reacted for 4 hours under circulating water at 50°C. After the reaction solution was left to age for 8 hours, the light yellow Mn was obtained after filtration, washing and drying. 0.8 Fe 0.2 C 2 o 4 2H 2 O material, denoted as QQT-A1.

[0055] in N 2 Dissolve 28.79 grams of ferrous nitrate in 2L of deionized water under protection, and after emulsification and dispersion, 179.12 grams of Mn 0.8 Fe...

Embodiment 2

[0073] This example is used to illustrate the lithium manganese iron phosphate provided by the present invention and its preparation method.

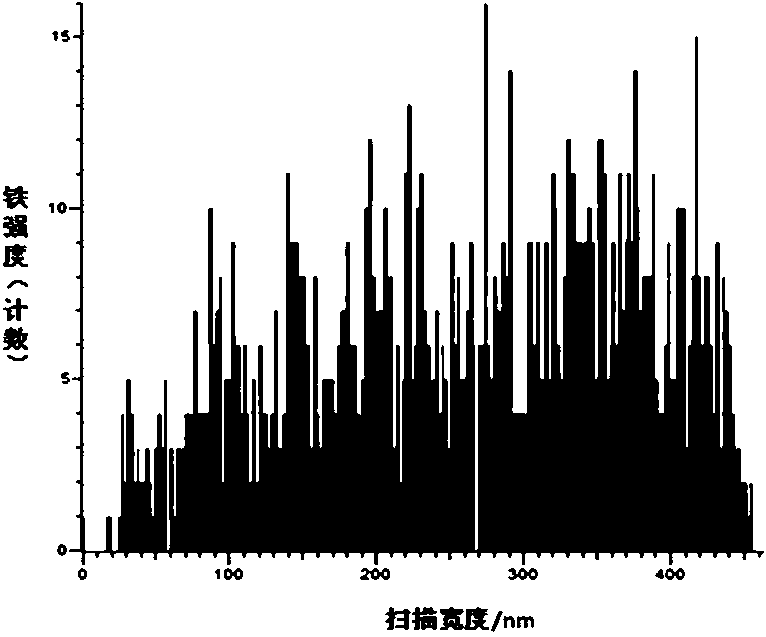

[0074] 139.12 grams of ferrous chloride tetrahydrate and 257.28 grams of manganous chloride tetrahydrate were respectively dissolved in 10L of deionized water, 267.98 grams of sodium oxalate were dissolved in 20L of deionized water, and then the ferrous chloride and manganous chloride At the same time, add it dropwise into the sodium oxalate solution in parallel, and control the pH of the reaction solution to 6 with dilute hydrochloric acid, stir and react for 2 hours under circulating water at 60°C, keep the reacted solution for 24 hours, filter, wash and dry Obtain light yellow Mn 0.65 Fe 0.35 C 2 o 4 2H 2 O material, denoted as QQT-A2.

[0075] in N 2 Dissolve 8.7 grams of ferrous acetate in 2L of deionized water under protection, and after emulsification and dispersion, 179.26 grams of Mn 0.65 Fe 0.35 C 2 o 4 2H 2 O powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com