Lithium-ion battery cathode active material limn x fe 1-x po 4 The preparation method of /c

A positive electrode active material, lithium-ion battery technology, applied in the direction of battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problem that lithium iron manganese phosphate is not a uniform single-phase crystal, and achieve uniformity consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

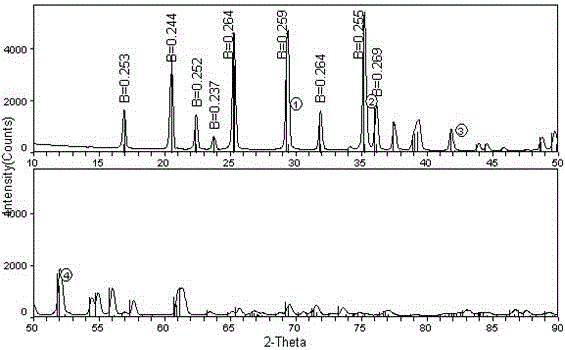

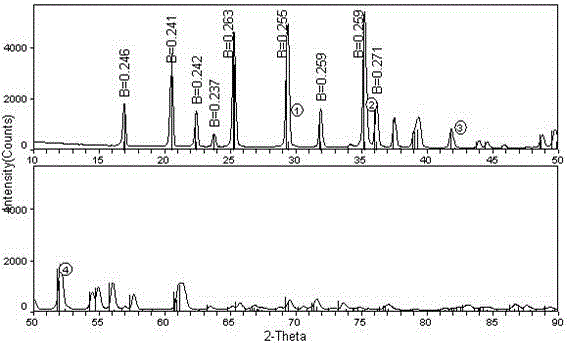

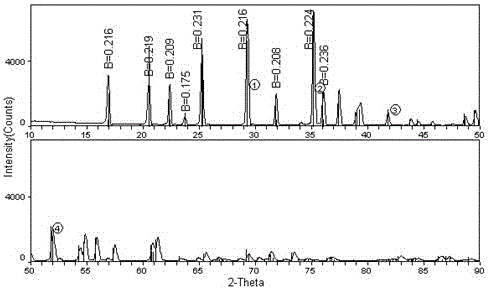

Image

Examples

preparation example Construction

[0023] The invention provides a lithium ion battery cathode active material LiMn x Fe 1-x PO 4 The preparation method of / C, the method may further comprise the steps:

[0024] S1, mixing soluble divalent manganese salt and soluble ferrous salt evenly to form a manganese-ferric salt mixture;

[0025] S2. Under the protection of inert gas, mix ferromanganese salt with complex precipitation agent, and prepare Mn by co-precipitation x Fe 1-x C 2 o 4 2H 2 O precursor;

[0026] S3, washing and drying the precursor to obtain precursor powder;

[0027] S4, under the protection of inert gas, the Mn x Fe 1-x C 2 o 4 2H 2 O precursor is mixed with soluble lithium salt and phosphate to obtain a precursor solution;

[0028] S5, reacting the precursor solution in an airtight container protected by an inert gas to obtain a reactant solution;

[0029] S6. After emulsifying and dispersing the carbon source into the reactant solution, dry it to obtain a mixture powder, sinter th...

Embodiment 1

[0053] 1L of 0.1mol / l concentration of ferrous sulfate and 1L of 0.1mol / l concentration of manganous sulfate solution were added dropwise to 1L of 0.2mol / l concentration of oxalic acid solution, while using ammonia to control the pH of the reaction solution to 7. Stir and react under circulating water at 40°C for 3 hours. After the reaction solution is left to age for 24 hours, filter, wash and dry to obtain light yellow Mn 0.5 Fe 0.5 C 2 o 4 2H 2 O Material A1.

[0054] 0.1mol of Mn 0.5 Fe 0.5 C 2 o 4 2H 2 O powder, 0.1mol lithium hydroxide, and 0.1mol phosphoric acid were added to 1L of deionized water, and the mixed solution was ball-milled in a ball mill for 1 hour, and then the solution after ball milling was transferred to a hydrothermal reaction kettle, under the protection of N2 at 180°C, After reacting for 16 hours under 1000rpm stirring, it was naturally cooled to room temperature, and the solution after the reaction was filtered, washed and dried 4 times to...

Embodiment 2

[0057] Add 1L of 0.4mol / l concentration of ferrous nitrate and 1L of 0.8mol / l concentration of manganous nitrate solution to 2L of 0.6mol / l concentration of sodium oxalate solution at the same time, and use sodium hydroxide to control the concentration of the reaction solution. The pH is 7.8, stirred and reacted for 4 hours under circulating water at 60°C, and the reacted solution was left to age for 48 hours, filtered, washed and dried to obtain light yellow Mn 0.67 Fe 0.33 C 2 o 4 2H 2 O material A2.

[0058] 0.5mol of Mn 0.67 Fe 0.33 C 2 o 4 2H 2 O powder and 0.5mol lithium dihydrogen phosphate were added to 1L of deionized water respectively, and the mixed solution was sand-milled in a sand mill for 2 hours, and the sand-milled solution was transferred to a hydrothermal reaction kettle. 1000rpm stirred and reacted for 24 hours, then naturally cooled to room temperature, and the solution after the reaction was filtered, washed and dried 4 times to obtain LiMn 0.67...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com