A kind of preparation method of power ncm cathode material

A positive electrode material and power technology, applied in the field of preparation of power NCM positive electrode materials, can solve the problems of no significant improvement in material cycle performance, high requirements, and increased processing costs for alcohol recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

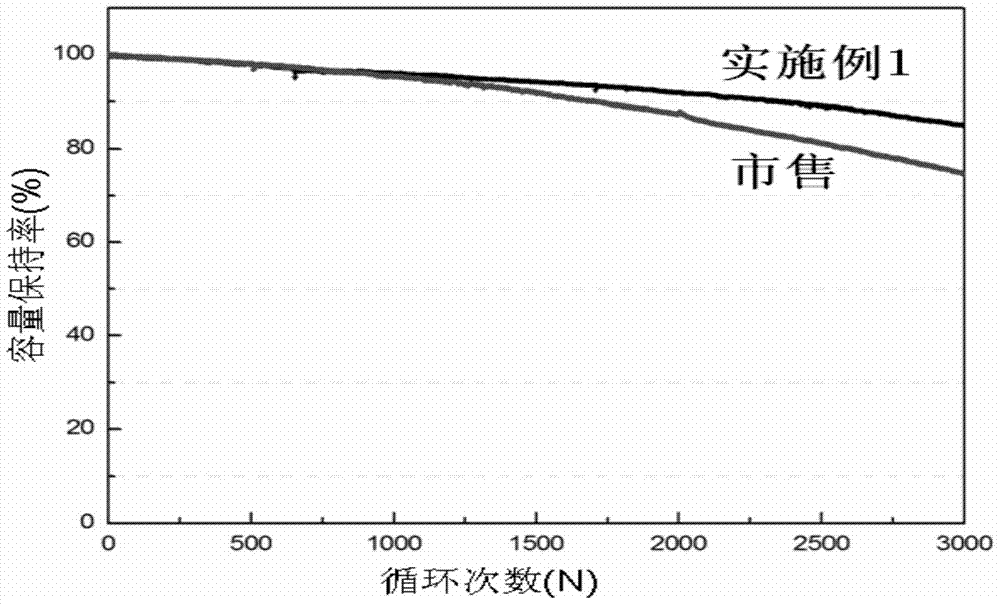

Embodiment 1

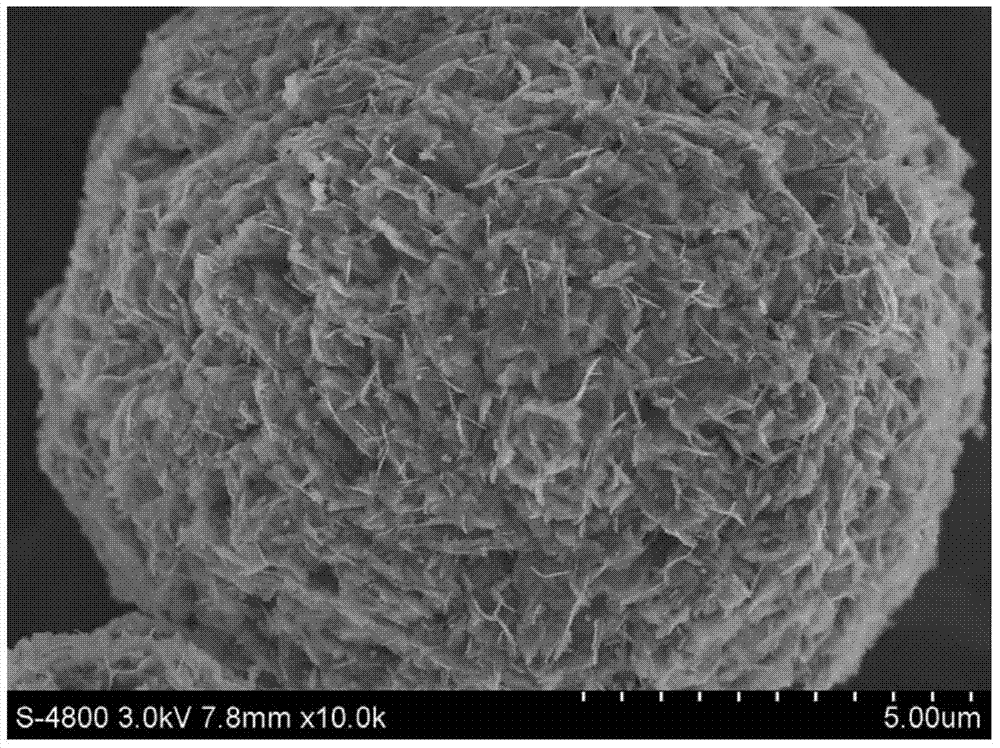

[0056] A kind of power NCM cathode material LiNi 0.33 co 0.36 mn 0.31 o 2 The preparation method comprises following process:

[0057] Step 1: Doped precursor Ni 0.33 co 0.36 mn .031 (OH) 2 preparation of

[0058] ⑴ Prepare the solution

[0059] Weigh NiSO according to the ratio of stoichiometric ratio 0.33:0.36:0.31 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O, according to finished LiNi 0.33 co 0.36 mn 0.31 o 2 The Al content in the medium is 750ppm, the Y content is 450ppm, and the Al(NO 3 ) 3 9H 2 O and Y (NO 3 ) 3 ·6H 2 O, formulated as Ni-Co-Mn-Al-Y-SO with a total metal ion content of 2mol / L for Ni, Co, and Mn 4 The mixed salt solution is recorded as solution a; NaOH is used as the precipitating agent and ammonia water is used as the complexing agent, and the precipitating agent solution and the complexing agent solution are mixed according to the ammonia-base molar ratio of 0.48, which is recorded as solution b, and the concentration of NaOH solutio...

Embodiment 2

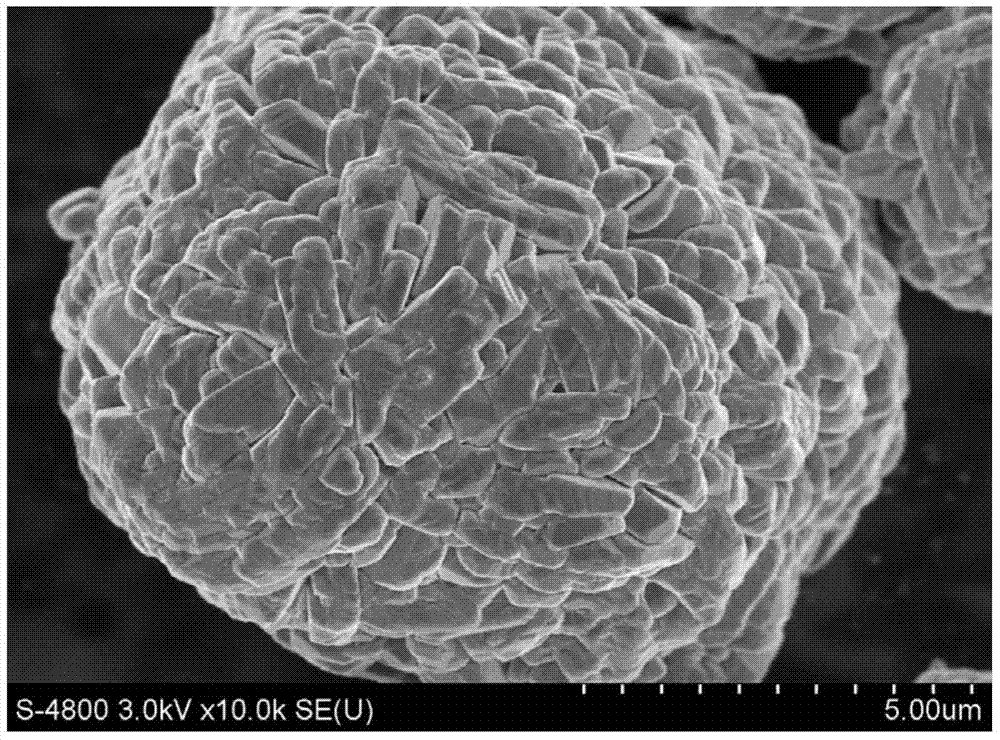

[0082] A kind of power NCM cathode material LiNi 0.5 co 0.2 mn 0.295 Y 0.005 o 2 The preparation method comprises following process:

[0083] Step 1: Precursor Ni 0.5 co 0.2 mn 0.295 Y 0.005 (OH) 2 preparation of

[0084] ⑴ Prepare the solution

[0085] Weigh NiSO according to the ratio of stoichiometric ratio 0.5:0.2:0.295:0.005 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O, Y (NO 3 ) 3 ·6H 2 O, formulated as Ni-Co-Mn-Y-SO with a total metal ion content of 2mol / L for Ni, Co, Mn, and Y 4 The mixed solution is recorded as solution a; with NaOH as the precipitating agent and ammonia as the complexing agent, the precipitant solution and the complexing agent solution are mixed according to the ammonia-alkali molar ratio of 0.35, which is recorded as solution b, and the concentration of NaOH solution is 12mol / L. The mass fraction of ammonia water is 25%.

[0086] (2) The reaction process of the two solutions

[0087] The two solutions of a and b are pumped in paral...

Embodiment 3

[0106] A kind of power NCM cathode material LiNi 0.6 co 0.2 mn 0..19 Y 0.01 o 2 The preparation method comprises following process:

[0107] Step 1: Precursor Ni 0.6 co 0.2 mn 0.19 Y 0.01 (OH) 2 preparation of

[0108] ⑴ Prepare the solution

[0109] Weigh NiSO according to the ratio of stoichiometric ratio 0.6:0.2:0.19:0.01 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O, Y (NO 3 ) 3 ·6H 2 O, formulated as Ni-Co-Mn-Y-SO with a total metal ion content of 2mol / L for Ni, Co, Mn, and Y 4 The mixed solution is recorded as solution a; with NaOH as the precipitating agent and ammonia as the complexing agent, the precipitant solution and the complexing agent solution are mixed according to the ammonia-alkali molar ratio of 0.30, which is recorded as solution b, and the concentration of NaOH solution is 12mol / L. The massfraction of ammoniacal liquor is 25%;

[0110] (2) The reaction process of the two solutions

[0111] The two solutions of a and b are pumped in paralle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com