Method for preparing lithium-zinc titanate/carbon nano composite negative electrode material

A carbon nanocomposite, lithium zinc titanate technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low conductivity, poor high rate performance, restrictions on promotion and application, etc., and achieve uniform particle size distribution , high rate performance, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

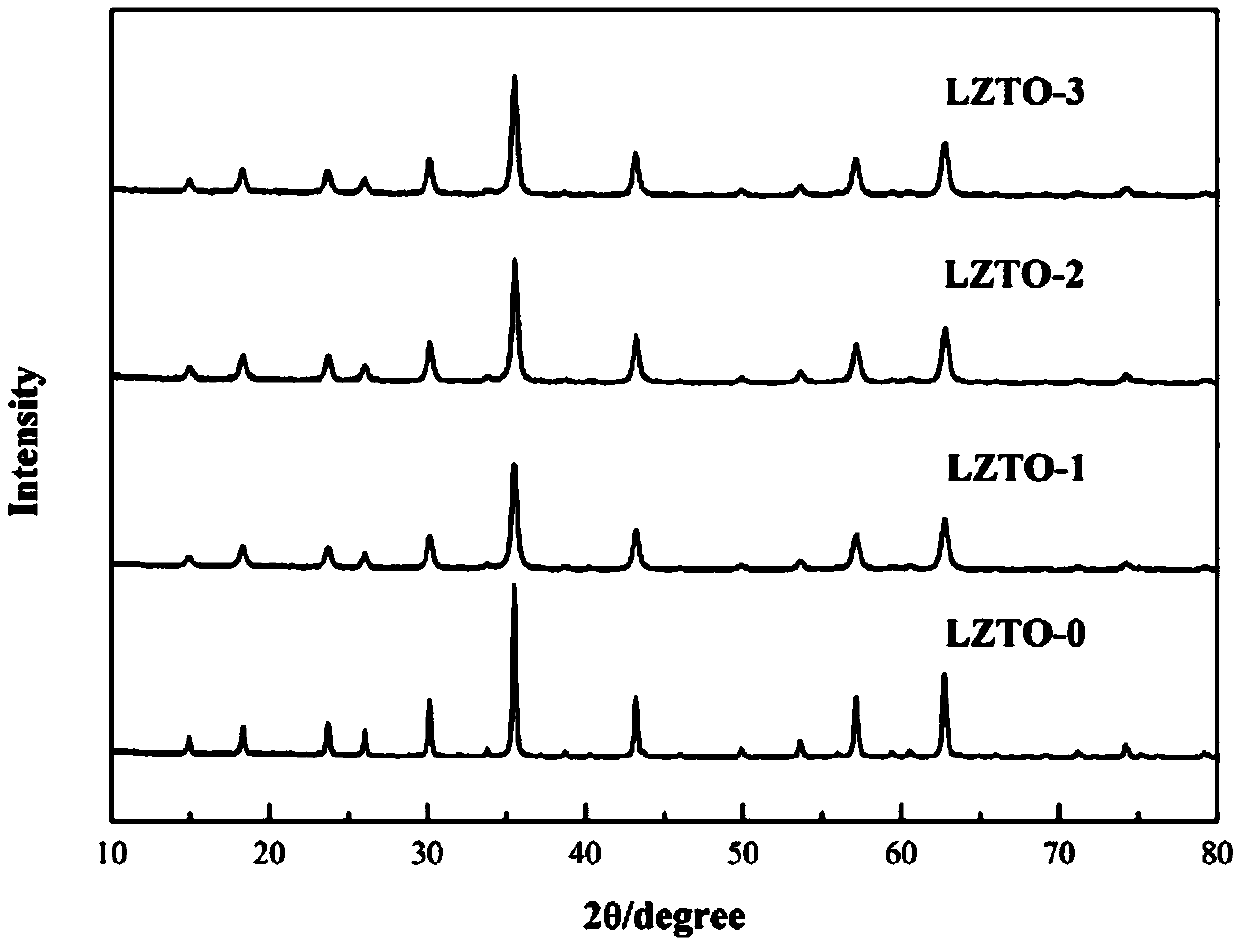

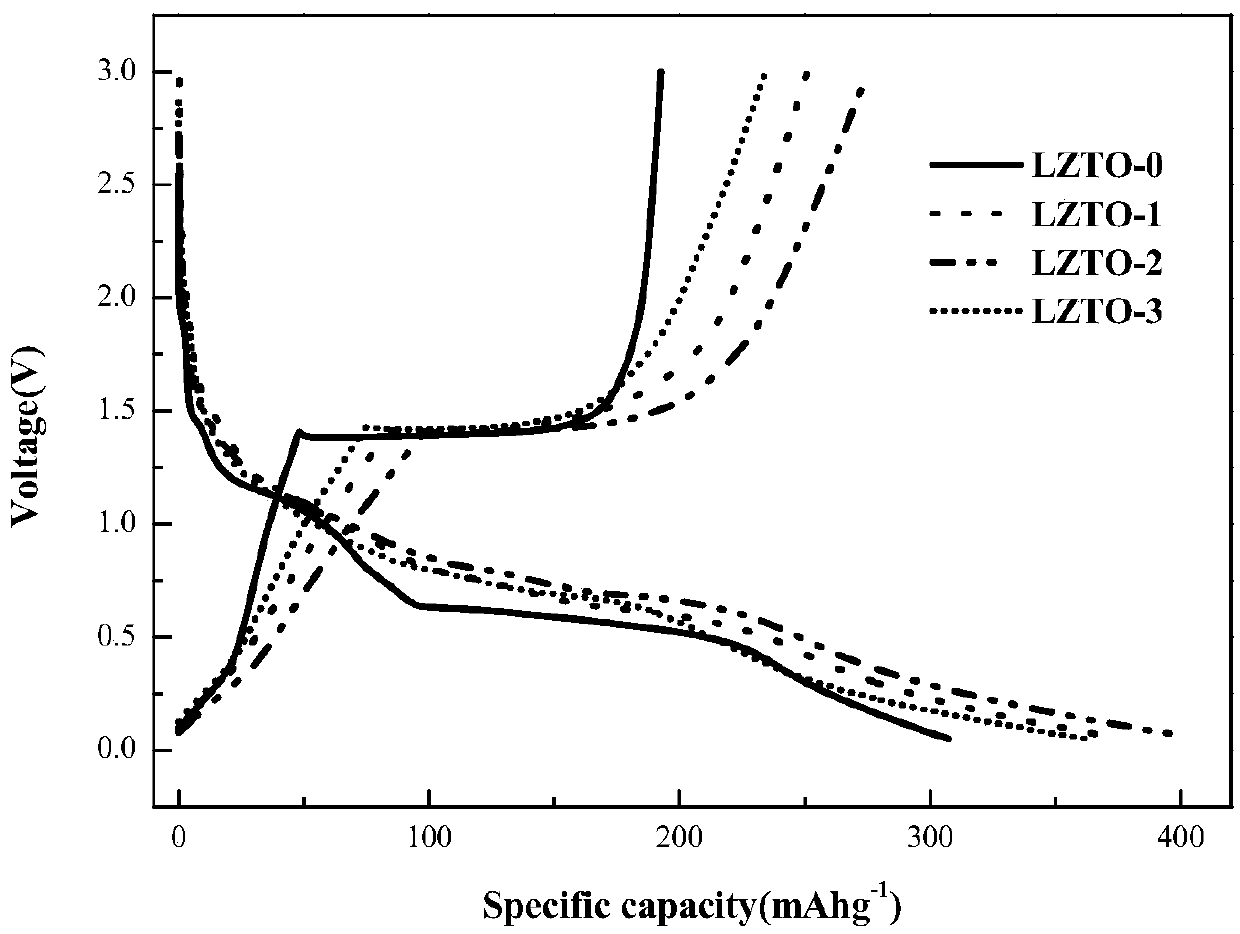

[0019] Li 2 ZnTi 3 o 8 Preparation of Nanoscale Anode Materials

[0020] Weigh 0.04mol of lithium acetate dihydrate and 0.02mol of zinc acetate dihydrate, add them to 200ml of absolute ethanol successively, stir magnetically until completely dissolved, and form a colorless solution; add 0.06mol of nano-titanium dioxide, sonicate for 20min, and stir for 1h at 25°C , to obtain a suspension; the suspension was evaporated to dryness in an oil bath at 80°C, and then vacuum-dried at 100°C to obtain a lithium zinc titanate precursor; Heat treatment for 10h. The sample is named: LZTO-0.

Embodiment 2

[0022] Li 2 ZnTi 3 o 8 / C composite anode material preparation

[0023] Weigh 0.04mol of lithium acetate dihydrate, 0.02mol of zinc acetate dihydrate and 0.5g of phenolic resin, add them to 200ml of absolute ethanol successively, stir magnetically until completely dissolved, and form a yellow solution; add 0.06mol of nano-titanium dioxide, ultrasonic 20min, 25 Stir at ℃ for 1 h to obtain a suspension; evaporate the suspension to dryness in an oil bath at 80 °C, and then dry it in vacuum at 100 °C to obtain a precursor of lithium zinc titanate / carbon composite material; the lithium zinc titanate / carbon The composite material precursor was heat-treated at 700 °C for 10 h in an argon atmosphere. Through elemental analysis, the carbon content in the obtained lithium zinc titanate / carbon composite material is 4.3%. The sample is named: LZTO-1.

Embodiment 3

[0025] Li 2 ZnTi 3 o 8 / C composite anode material preparation

[0026] Weigh 0.04mol of lithium acetate dihydrate, 0.02mol of zinc acetate dihydrate and 0.7g of phenolic resin, add them to 200ml of absolute ethanol successively, stir magnetically until completely dissolved, and form a yellow solution; add 0.06mol of nano-titanium dioxide, ultrasonic for 20min, Stir at ℃ for 1 h to obtain a suspension; evaporate the suspension to dryness in an oil bath at 80 °C, and then dry it in vacuum at 100 °C to obtain a precursor of lithium zinc titanate / carbon composite material; the lithium zinc titanate / carbon The composite material precursor was heat-treated at 700 °C for 10 h in an argon atmosphere. Through elemental analysis, the carbon content in the obtained lithium zinc titanate / carbon composite material is 6.0%. The sample is named: LZTO-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com