A device and operation method for copper electrolysis or copper electrowinning

A technology of copper electrolysis and copper electrolysis, which is applied in the field of copper electrolysis, can solve the problems of not being able to effectively reduce concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

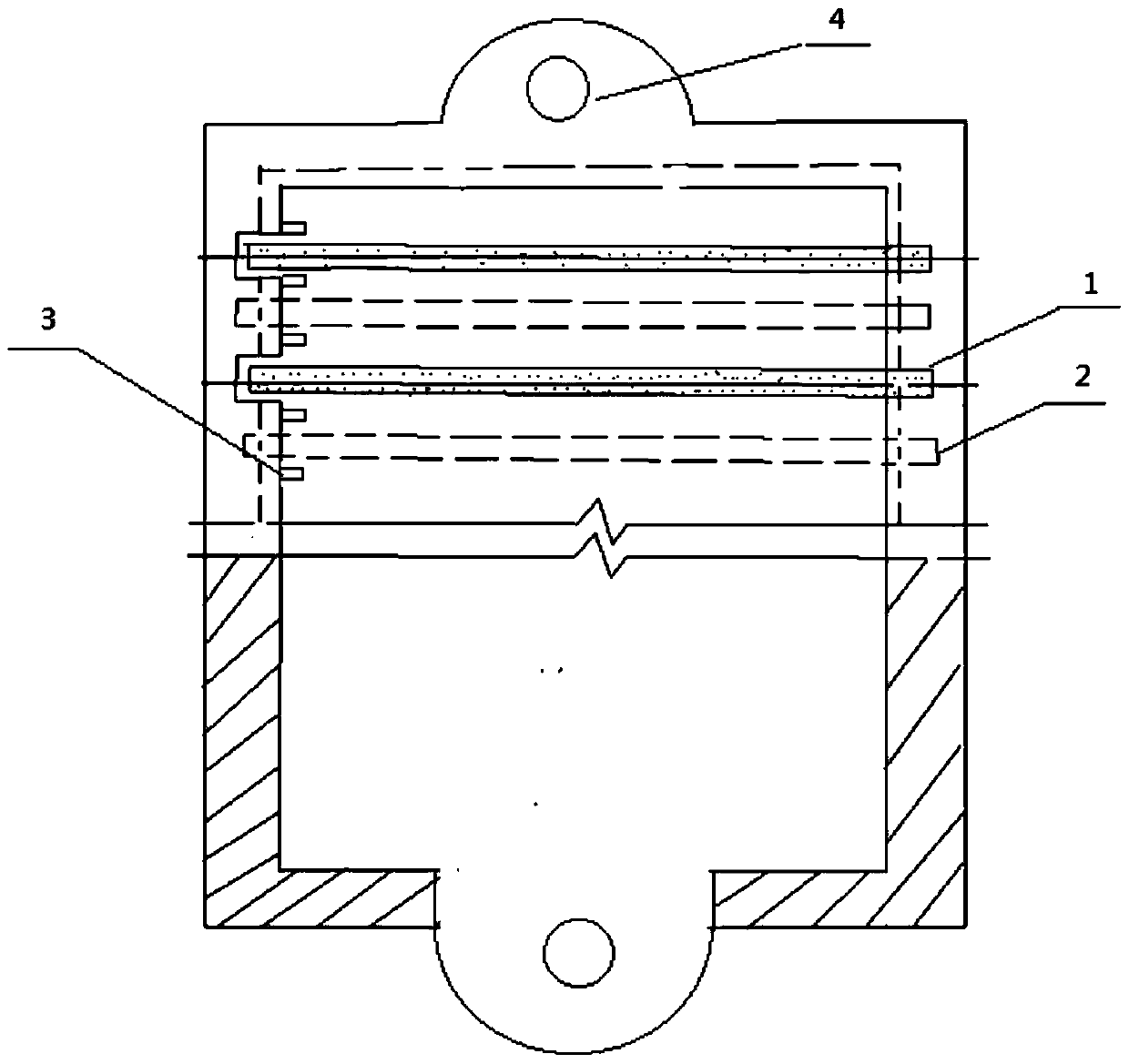

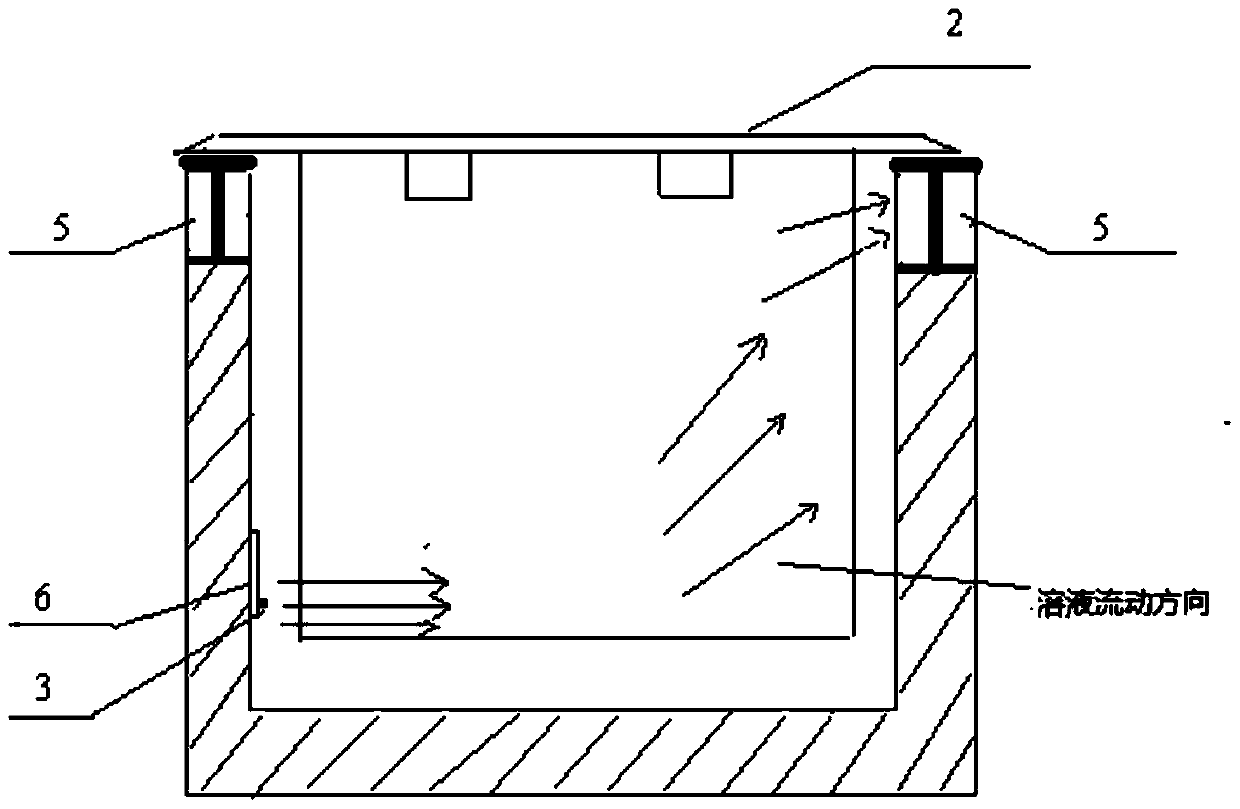

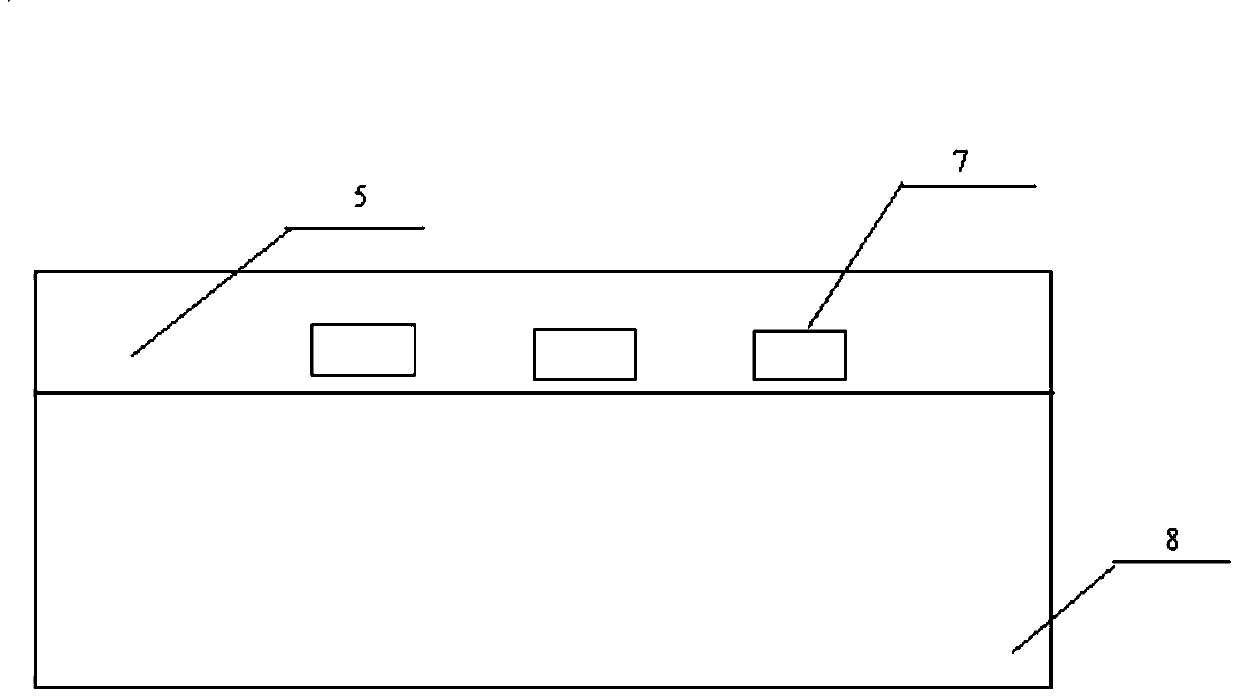

Embodiment 1

[0041] 53 pieces of copper anodes and 52 pieces of stainless steel cathodes are installed in the electrolytic cell, and the stainless steel box in the electrolytic cell is connected through a liquid inlet pipe, and the electrolyte enters the stainless steel box in the electrolytic cell through the liquid supply pipe; at the bottom of the electrolytic cell The stainless steel box is fixed at a height of 500mm. The liquid outlet nozzle is located at the lower part of the box. Two liquid outlet nozzles are evenly distributed on both sides of the bottom of each cathode plate. The inner diameter of the nozzle is Φ8mm and the outer diameter is Φ14mm; the electrolyte passes through the outlet The liquid nozzle sprays out at a flow rate of 0.4m / s, and the flow rate of each liquid nozzle is 0.85L / min; after the electrolyte is sprayed out, it flows back through the overflow ports reserved at the two long side grooves on the upper part of the electrolytic cell. Gather to the main liquid r...

Embodiment 2

[0044] The application of copper electrowinning can be used for the purification, decopper and impurity removal of electrolyte

[0045] With the progress of the electrolysis process, copper and impurity elements are continuously enriched, and a certain amount of waste electrolyte needs to be processed every day for decopper and impurity removal; the waste electrolyte of the main system is pumped to the electrowinning tank of the cleaning process for decopper , Removal of impurities.

[0046] Put 24 insoluble lead anode plates into the electrowinning tank as anodes for copper electrowinning, and pack 23 stainless steel cathode plates or cathodes whose residues are copper electrowinning (each group of electrowinning tanks has 10 slots in total, and the first 3 slots are loaded Stainless steel cathode plate, the last 7 tanks are filled with the residual electrode after electrolysis as the cathode of copper electrowinning), the waste electrolyte of the main system enters the stain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com