Closed structure applied to building construction process and construction process thereof

A technology for building construction and closed structures, applied to building components, building insulation materials, etc., can solve the problems of high cost, time-consuming, cumbersome procedures, etc., and achieve the effects of saving costs, facilitating construction, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

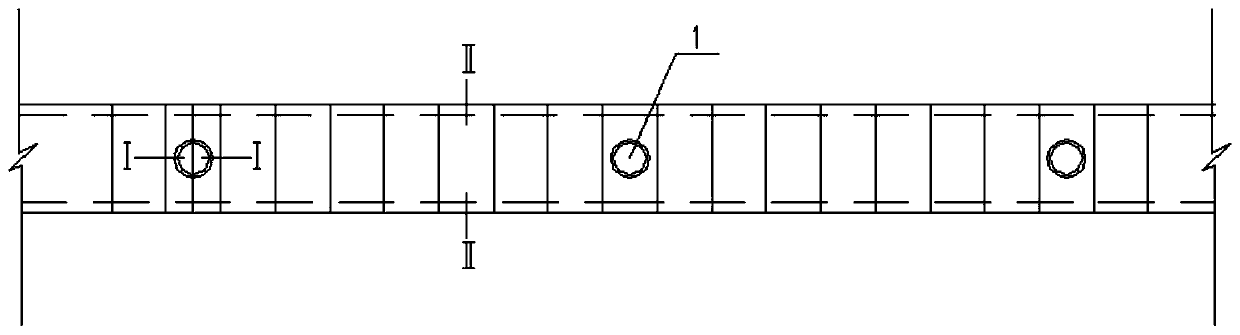

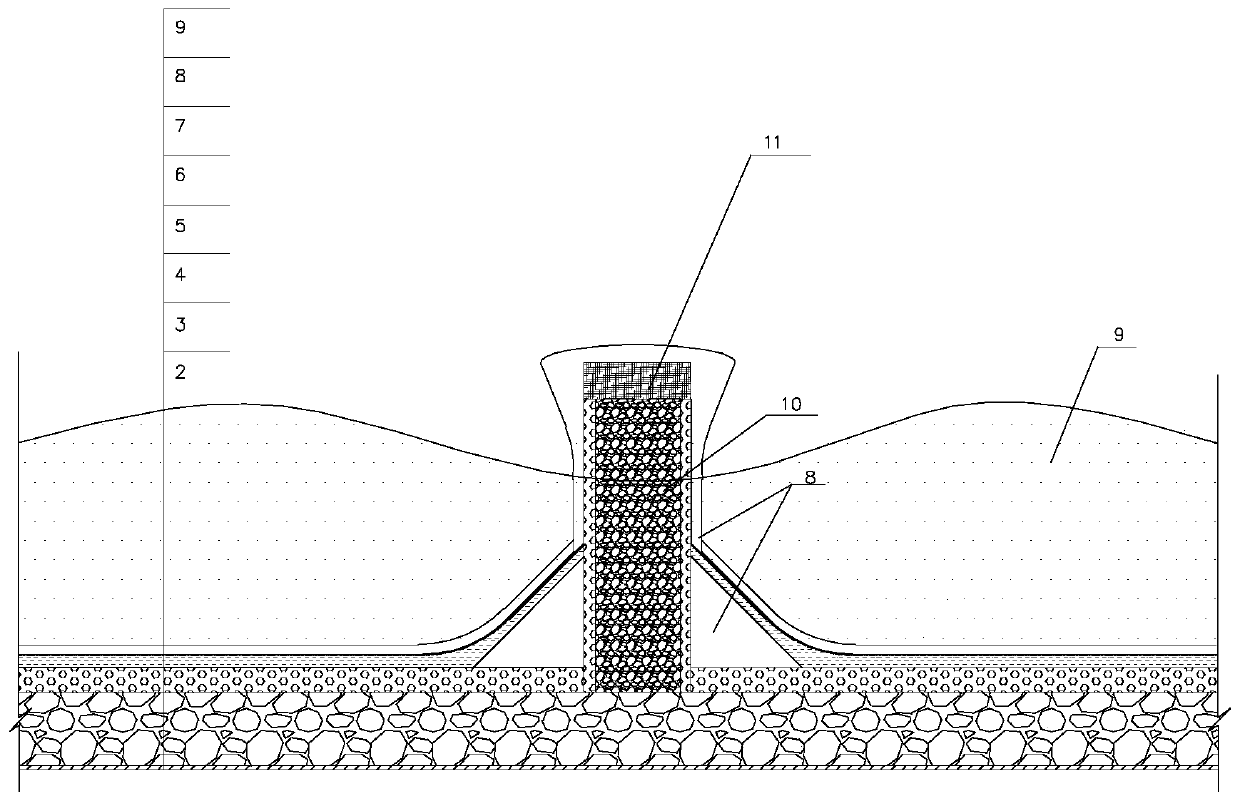

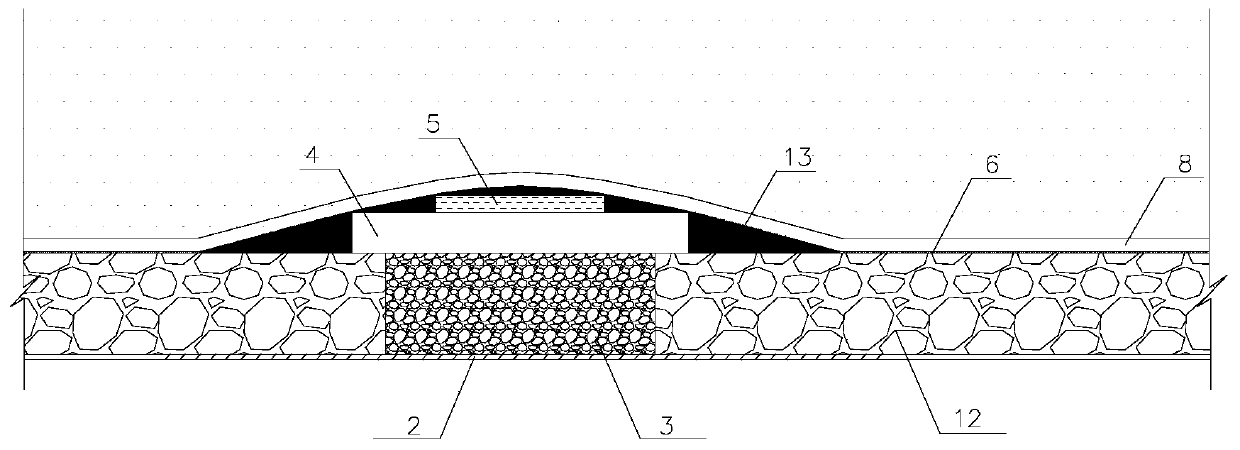

[0029] see Figure 1-3 , a closed structure used in the building construction process and its construction technology, including a steel plate 4, a steel pipe is arranged on the steel plate 4, and a pouring hole is arranged on the steel pipe, and the lower surface of the steel plate 4 is sequentially provided with automatic The dense concrete 3 and the post-casting belt formwork 2, the upper surface of the self-compacting concrete 3 is connected with the steel plate 4, and the lower surface is connected with the post-casting belt formwork 2, and the upper surface of the steel plate 4 is provided with a protective component.

[0030] In this embodiment, in order to better use the protective assembly, the protective assembly is sequentially connected with extruded board 5, waterproof membrane 6, isolation layer 7, fine stone concrete rigid protective layer 8 and backfill soil 9 from bottom to top, The lower surface of the extruded board 5 is connected to the steel plate 4, so th...

Embodiment 2

[0036] A construction technique for a closed structure applied in a building construction process, characterized in that it comprises the following steps:

[0037] Step 1: Prepare various raw materials: steel pipe, post-casting strip formwork 2, self-compacting concrete 3 (micro-expansion), steel plate 4, extruded board 5, waterproof membrane 6, isolation layer 7, fine stone concrete rigid protective layer 8, Backfill soil 9, glass fiber bag 10, plastic cloth 11, basement roof 12 and cement mortar 13;

[0038] Step 2: Lay the steel plate 4 on the upper side of the post-casting strip formwork 2, and use cement mortar 13 on both sides of the steel plate 4 to level the slope, so as to construct the waterproof coiled material 6 and the protective layer;

[0039] Step 3: The upper side of the formwork of the post-pouring belt of the floor slab is covered with a steel plate, and holes are reserved on the steel plate, and then the steel pipe and the steel plate 4 are welded together ...

Embodiment 3

[0046] On the basis of Example 2, when the closed structure of the present invention is in use, the upper side of the post-casting belt of the floor is covered with a steel plate 4, and holes are reserved on the steel plate 4, and then the steel pipe and the steel plate 4 are welded together. A steel pipe pouring hole 1 is formed. The waterproof layer and protective layer are constructed simultaneously with the overall structure, the steel pipe pouring hole 1 is filled with glass fiber bag 10 and plastic cloth 11 for protection, and the backfill soil 9 is constructed; after the structure settles stably, self-compacting concrete 3 can be poured from the steel pipe pouring hole 1 (micro expansion).

[0047]The post-cast tape formwork 2 used must be disconnected from the large-area formwork and support, and the support must be provided with relatively independent horizontal braces, vertical poles and scissors braces; The support does not move, and before closing the construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com