Sulfuric acid resistant ferritic stainless steel and manufacturing method thereof

A manufacturing method and technology of sulfuric acid resistance, which is applied in the fields of waste gas desulfurization devices, sulfur-containing waste gas chimneys, and flues, which can solve the problems of high price, general corrosion resistance of dilute sulfuric acid, insufficient impact toughness and weldability, etc., and achieve improved weld seam Plasticity, resistance to a wide range of sulfuric acid concentrations, and the effect of improving low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with embodiment.

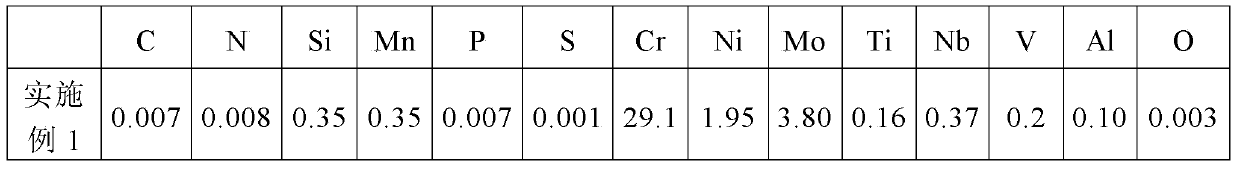

[0060] The chemical composition of ferritic stainless steel for sulfuric acid resistance in the embodiment of the present invention and the steel of the comparative example is shown in Table 1, and the rest is Fe and unavoidable impurities. Table 2 and Table 3 show the key process parameters of ferritic stainless steel for sulfuric acid resistance in the embodiment of the present invention and the comparative example steel. Comparative Example 1 is ordinary high-chromium ferritic stainless steel 445, and Comparative Example 2 is super austenitic stainless steel 904L.

[0061] The three-step smelting process (EF+AOD+VOD) is used for smelting and continuous casting. First, the desiliconized and dephosphorized blast furnace molten iron and 400 series stainless steel scrap are mixed into the electric furnace EF in a certain proportion, and high-carbon Cr-Fe alloy is added to carry out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com