Polyaniline-modified cement-based antirust paint and preparation method and application thereof

An anti-rust coating and polyaniline technology, applied in cement coatings, anti-corrosion coatings, coatings, etc., can solve problems such as affecting the construction performance of coatings and restricting wide application, and achieve the improvement of electrochemical corrosion potential and grip strength. , Improve the effect of delayed liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

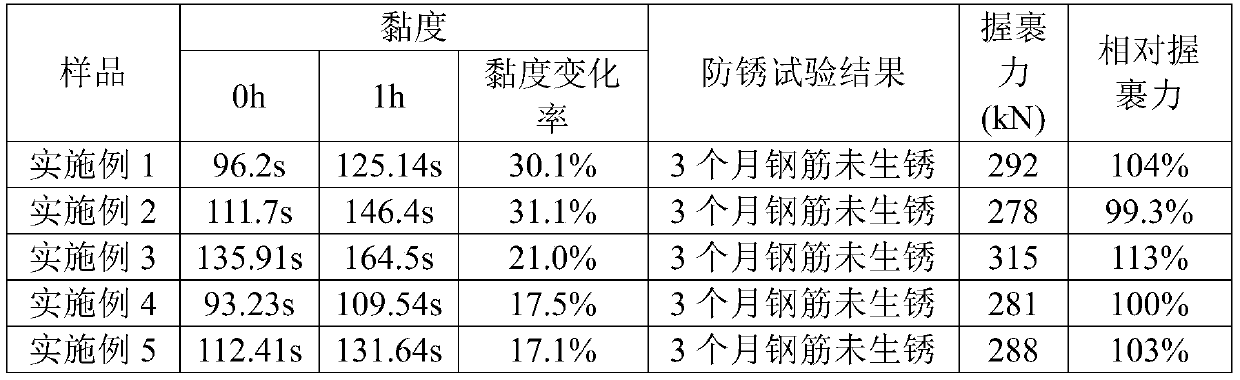

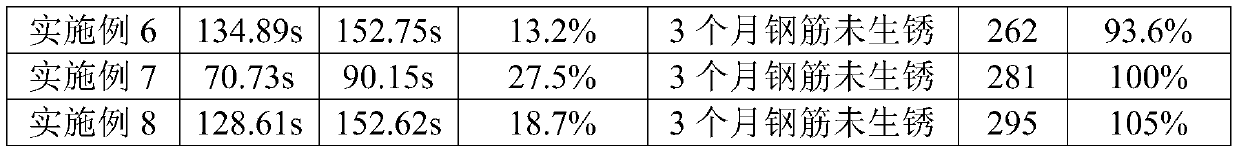

Embodiment 1

[0029]A polyaniline-modified cement-based antirust coating, based on cement quality, each component is composed of: 1kg (100wt%) of ordinary Portland cement of strength grade 52.5, polyaniline 10g (1wt%), RI Steel bar rust inhibitor 30g (3wt%), naphthalene series powder water reducer 5g (0.5wt%), sodium lignosulfonate 2g (0.2wt%), water 400g (40wt%). Prepare according to the preparation method described in the present invention, carry out the viscosity test and the viscosity test after 1h with Tu-4 cup viscometer. Then use a 25mm brush to coat the prepared anti-rust paint on the surface of the steel bar, put the short steel bar in 3.5wt% saline solution for anti-rust experiment after standing for 7 days, and then press the long steel bar with C50 concrete According to the industry standard of strength test (JTJ270-98 "Concrete Test Regulations for Water Transport Engineering"), molds were built, demoulded after 48 hours and cured in a curing room at 20°C and humidity 100% for ...

Embodiment 2

[0031] A polyaniline-modified cement-based antirust coating, raw materials are composed of: 1kg (100wt%) of ordinary portland cement of strength grade 52.5, 20g (2wt%) of polyaniline, 30g (3wt%) of RI steel bar rust inhibitor , 5g (0.5wt%) of naphthalene-based powder water reducer, 2g (0.2wt%) of sodium lignosulfonate, and 400g (40wt%) of water. Prepare according to the preparation method described in the present invention, carry out the viscosity test and the viscosity test after 1h with Tu-4 cup viscometer. Then use a 25mm brush to coat the prepared anti-rust paint on the surface of the steel bar, put the short steel bar in 3.5wt% saline solution for anti-rust experiment after standing for 7 days, and then press the long steel bar with C50 concrete According to the industry standard of strength test (JTJ270-98 "Concrete Test Regulations for Water Transport Engineering"), molds were built, demoulded after 48 hours and cured in a curing room at 20°C and humidity 100% for 28 da...

Embodiment 3

[0033] A polyaniline-modified cement-based antirust paint, raw materials are composed of: 1kg (100wt%) of ordinary portland cement of strength grade 52.5, polyaniline 30g (3wt%), RI steel bar rust inhibitor 30g (3wt%) , 5g (0.5wt%) of naphthalene-based powder water reducer, 2g (0.2wt%) of sodium lignosulfonate, and 400g (40wt%) of water. Prepare according to the preparation method described in the present invention, carry out the viscosity test and the viscosity test after 1h with Tu-4 cup viscometer. Then use a 25mm brush to coat the prepared anti-rust paint on the surface of the steel bar, put the short steel bar in 3.5wt% saline solution for anti-rust experiment after standing for 7 days, and then press the long steel bar with C50 concrete According to the industry standard of strength test (JTJ270-98 "Concrete Test Regulations for Water Transport Engineering"), molds were built, demoulded after 48 hours and cured in a curing room at 20°C and humidity 100% for 28 days, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity change rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com