Acid-modified potash water glass-fluorocarbon-modified styrene-acrylic emulsion composite coating and preparation method thereof

A potassium water glass, styrene-acrylic emulsion technology, applied in the direction of alkali metal silicate coatings, anti-corrosion coatings, coatings, etc., can solve the problems of unsatisfactory corrosion resistance, reduced colloid water resistance, etc., to reduce moisture absorption, Increased water resistance, high chemical resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

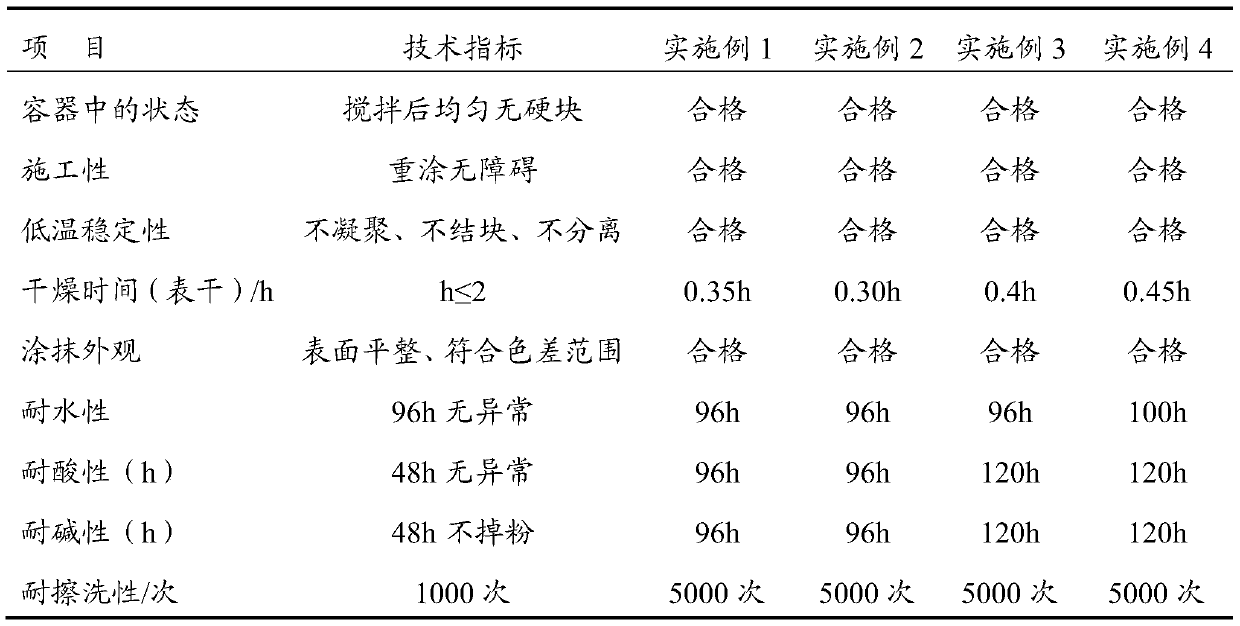

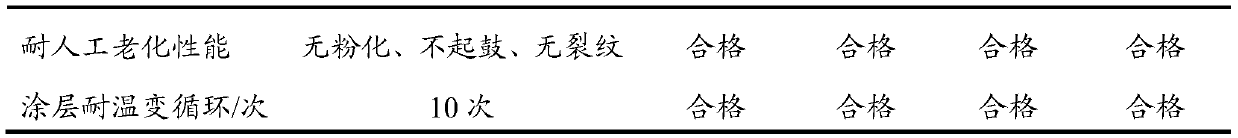

Embodiment 1

[0038] Embodiment 1 (for the exterior wall of the acid volatilization workshop)

[0039] Preparation of acid-modified potassium silicate: Weigh 76% of the modulus ratio as SiO 2 / K 2 O=4, concentration is 30% potassium water glass, put potassium water glass into the dispersing and stirring equipment, under 1300rpm high-speed stirring, slowly add 0.6% stabilizer tin mercaptide and pure water, stir evenly, Then add 1% hydrochloric acid to adjust the pH value of the potassium water glass to 11 to obtain acid-modified potassium water glass. Weigh 22 parts of acid-modified potassium water glass for use.

[0040] Preparation of fluorocarbon modified styrene-acrylic emulsion: Add 60% BC-01 styrene-acrylic emulsion into a four-necked bottle, stir at 300rpm, raise the temperature to 75°C, slowly add 8% fluorocarbon emulsion dropwise, and slowly Slowly add 0.9% aminoethylaminopropyl polydimethylsiloxane, then add 0.8% octylphenol polyoxyethylene ether, 0.01% polyether modified polys...

Embodiment 2

[0043] Embodiment 2 (for the exterior wall of the acid volatilization workshop)

[0044] Preparation of acid-modified potassium silicate: Weigh 78% of the modulus ratio as SiO 2 / K 2 O=4, concentration is 30% potassium water glass, potassium water glass is put into dispersion mixing equipment, under 1300rpm high-speed stirring, slowly add 0.7% stabilizer tin mercaptide and pure water, stir evenly, Then add 1.1% hydrochloric acid to adjust the pH of the potassium water glass to 11 to obtain acid-modified potassium water glass. Weigh 20 parts of acid-modified potassium water glass for use.

[0045] Preparation of fluorocarbon modified styrene-acrylic emulsion: Add 60% BC-01 styrene-acrylic emulsion into a four-necked bottle, stir at 400rpm, raise the temperature to 74°C, slowly add 7.5% fluorocarbon emulsion dropwise, and slowly Slowly add 0.8% aminoethylaminopropyl polydimethylsiloxane, then add 0.8% octylphenol polyoxyethylene ether, 0.01% polyether modified polysiloxane ...

Embodiment 3

[0048] Embodiment 3 (for the interior wall of the acid volatilization workshop)

[0049] Preparation of acid-modified potassium silicate: Weigh 80% of the modulus ratio as SiO 2 / K 2 O=4, concentration is 30% potassium water glass, put potassium water glass into the dispersing and stirring equipment, under 1500rpm high-speed stirring, slowly add 0.9% stabilizer tin mercaptide and pure water, stir evenly, Then add 1.2% hydrochloric acid to adjust the pH value of the potassium water glass to 11 to obtain acid-modified potassium water glass. Weigh 25 parts of acid-modified potassium water glass for use.

[0050] Preparation of fluorocarbon modified styrene-acrylic emulsion: Add 70% BC-01 styrene-acrylic emulsion into a four-necked bottle, stir at 400rpm, raise the temperature to 76°C, slowly add 9% fluorocarbon emulsion dropwise, and slowly Slowly add 1% aminoethylaminopropyl polydimethylsiloxane, then add 1% octylphenol polyoxyethylene ether, 0.02% polyether modified polysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com