Rapid sintering preparation method of infrared transparent ceramic

A technology for transparent ceramics and rapid sintering, applied in the field of transparent ceramic material preparation, can solve the problems of shortening the heating time and reducing the sintering activity of powders, achieves grain refinement, low production cost, and inhibits abnormal grain size growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

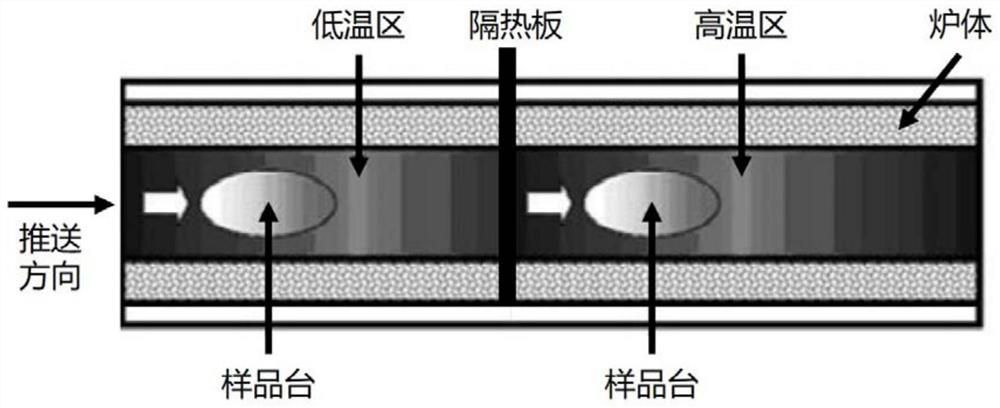

Method used

Image

Examples

Embodiment 1

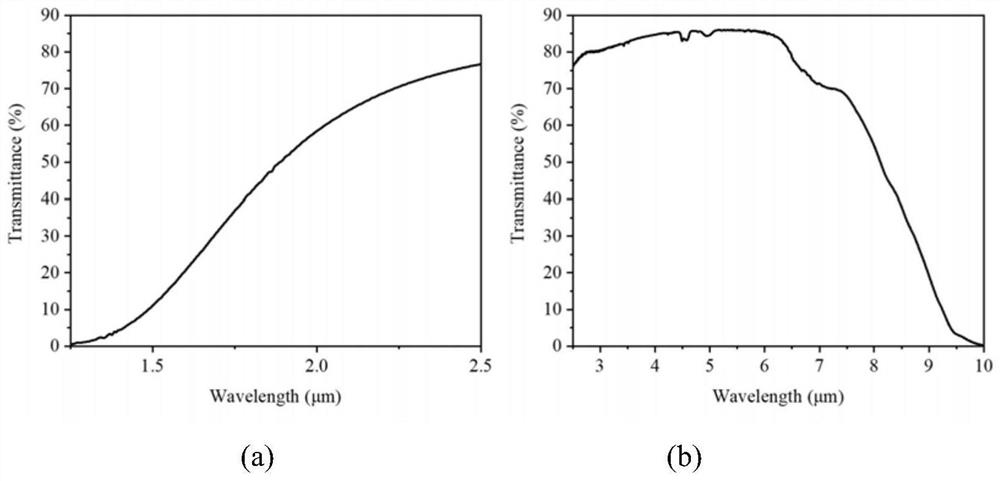

[0034] Use Y 2 O 3 -MGO composite nanoparticles, weigh 20g powder The mold pressurization is 3 MPa dry pressure as a ceramic blank, and the blank is pressured for 280 MPa, and the pressure retaining time is 3 min is static. The high temperature zone is hit by the high temperature zone of the muffle to 1600 ° C to be used, and the ceramics On the low temperature zone platform of the muffle furnace, the temperature is increased to 1200 ° C for 200 min at 1 ° C / min; lift the heat insulating plate of the high temperature zone and the low temperature zone to quickly push the sample table and the sample to the high temperature zone, carry out 10 min After the insulation is sintered, after the sintering is completed, the furnace is cooled, and the high-density nano-grain ceramic sample is obtained; then perform two high-precision mirror polishing processing, which has a thickness of 3.0mm. 2 O 3 -MGO nano-phase ceramic product.

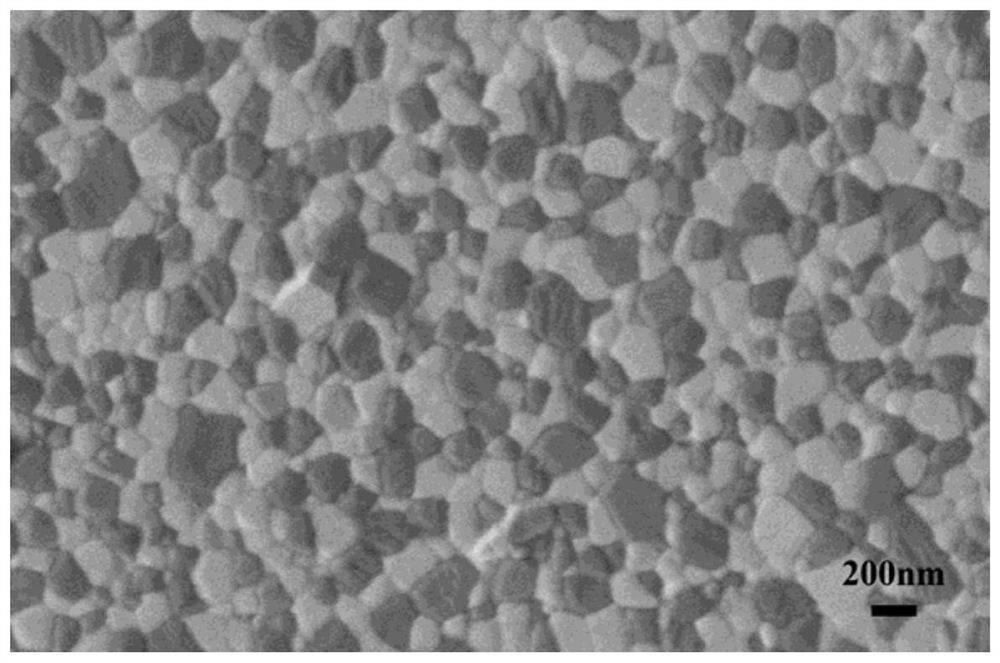

[0035] figure 2 Yes made in Example 1 2 O 3 -Mgo nano-...

Embodiment 2

[0038] Using commercial ZRO 2 Nanofin, weigh 80g powder The mold pressurization is 30 MPa to ceramic billet, and the blank is pressured for 180 MPa, and the pressure pressure time is 20 min, and the high temperature zone is hit by the high temperature zone of the muffle to 1200 ° C to be used, and the ceramics On the sample table of the Maververter Holtaicone, the temperature is warmed to 800 ° C for 10 min at a temperature of 5 ° C / min; lift the heat insulating plate of the high temperature zone and the low temperature zone to quickly push the sample table and the sample to the high temperature zone. 200min insulation sintering, after the end of sintering, the furnace is cooled, produce high-density nano-grain ceramic samples; then carry out double-sided high-precision mirror polishing, obtain ZRO having a thickness of 3.0 mm 2 Ceramic product.

[0039] Figure 4 Zro made in Example 2 2 Ceramic SEM topography; It can be seen from the figure that the average grain size is withi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com