Moisture resistance packaging film

A packaging film and moisture-proof technology, which is applied in packaging, wrapping paper, household packaging, etc., can solve the problems of affecting the quality of packaged food, moisture in the outside, and easy absorption of moisture, etc., to achieve large market promotion and application value, simple structure, and improved The effect of moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

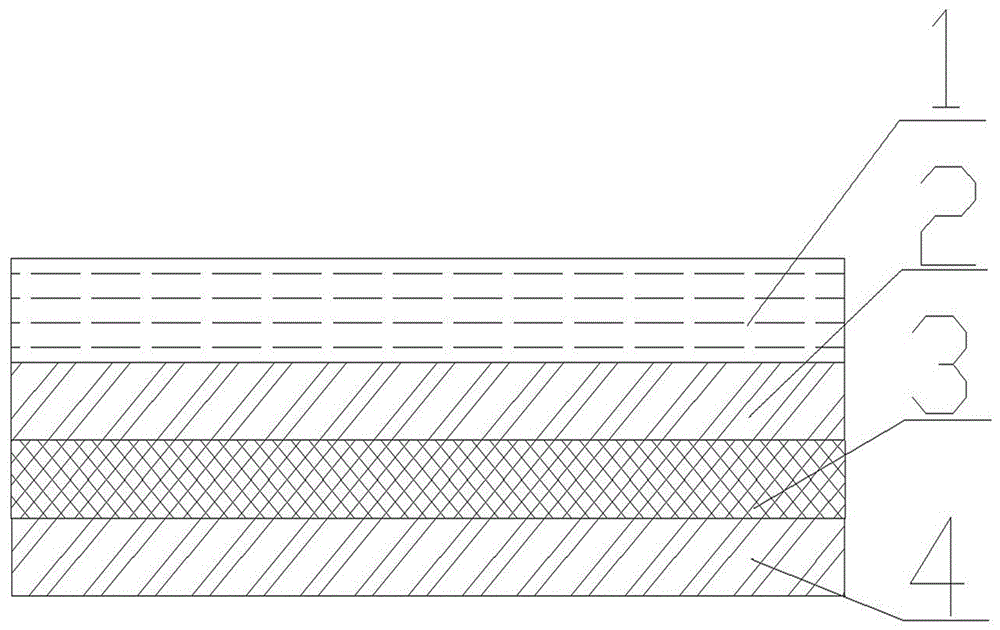

[0025] Such as figure 1 As shown, a moisture-proof packaging film, including an Aclar film layer 1, a PVDC film layer 2 that blocks water vapor, and a heat-sealing layer blown from polyethylene particles modified by montmorillonite masterbatches in sequence from the inside to the outside 3. The upper end of the heat-sealing layer 3 is bonded to the printed film layer 4 for printing the required pattern of packaging through an adhesive; the Aclar film layer 1, PVDC film layer 2, heat-sealing layer 3, and printed film layer 4 Both are bonded with polyurethane adhesive.

[0026] Among them, the Aclar film layer 3 is a polychlorotrifluoroethylene film with excellent barrier properties and chemical stability advantages. Aclar film 3 has a composite barrier film that can reduce cross-permeation and effectively isolate water vapor. It is the preferred material for solid food packaging to avoid moisture absorption. Aclar film 3 film is crystal clear and transparent, does not contain...

Embodiment 2

[0030] In this embodiment, on the basis of Embodiment 1, the printed film layer 4 is a PA film, and a polyvinyl alcohol coating is provided between the printed film layer 4 and the heat-sealing layer. The Aclar film layer 3 is a fluorine-containing polymer film layer, and the Aclar film is a polychlorotrifluoroethylene material, which has excellent water blocking properties and can effectively prevent external moisture from entering the food packaging bag. The coating amount of the Aclar film layer 3 is 2-3.5g / m3. The coating amount of the Aclar film layer 3 depends on the degree of fusion with the PVDC film layer 2. The two can be well glued together and have good formability. Other structures and principles involved in this embodiment are common knowledge in the field and will not be repeated here.

Embodiment 3

[0032] In this embodiment, on the basis of the above embodiments, the printed film layer 1 is further described as a transparent stretched film. The material used for the printing film layer 1 is any one of BOPP, BOPET and BOPA. The printing film layer 1 is the outermost layer of the packaging film, which is convenient for printing characters, patterns and the like. Other structures and principles involved in this embodiment are common knowledge in the field and will not be repeated here.

[0033] The solid food packaging bag described in this embodiment not only satisfies transparency and is convenient for users to observe, but also has strong moisture resistance to prevent external water vapor or moisture from entering the packaging bag and affecting the quality of food. In addition, it is convenient for consumers to use, and there is no need to worry about losing the desiccant bag, or it must be used within the specified time, which is very convenient for consumers and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com