Rubber insulation material for rubber sleeve power cable with rated voltage of 35 kV or above

A power cable, rated voltage technology, applied in the direction of rubber insulators, organic insulators, etc., to achieve the effect of increasing toughness, promoting uniform dispersion, and increasing flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

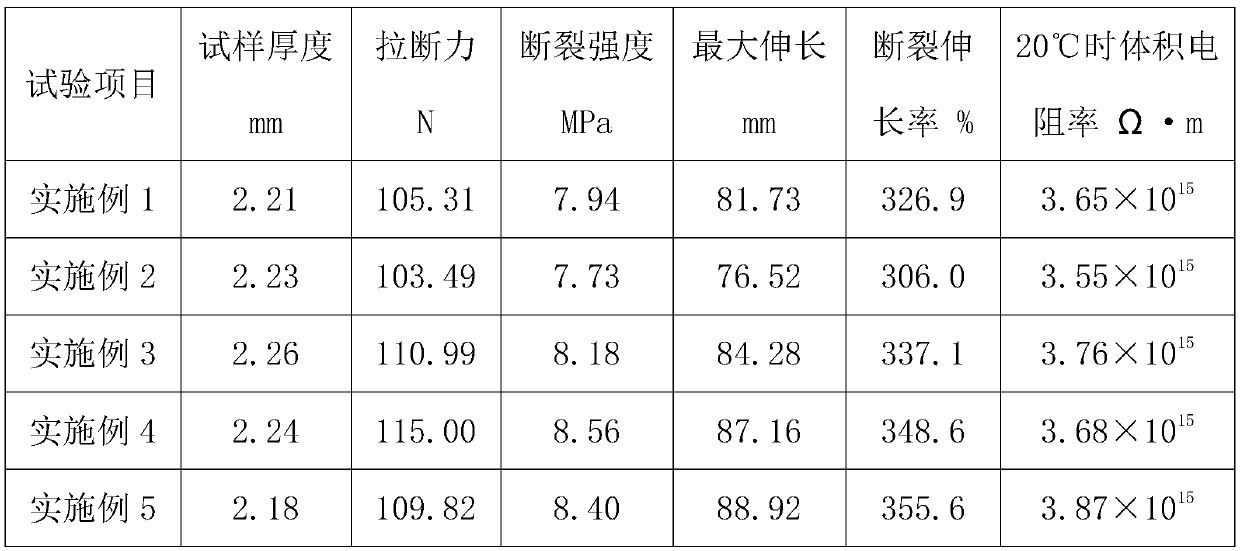

Examples

Embodiment 1

[0020] A rubber insulating material for rubber-sheathed power cables with a rated voltage above 35kV, the raw materials of which include by weight: ter404470 parts of ethylene-propylene-diene rubber, 40 parts of methyl vinyl silicone rubber, 20 parts of ethylene-butylene elastomer, 4 parts of paraffin wax 11 parts of paraffin oil, 2 parts of anti-aging agent MB, 2641 parts of anti-aging agent, 8 parts of zinc oxide, 0.5 part of stearic acid, 10 parts of modified calcium carbonate with a particle size of 100nm, 130 parts of modified fine kaolin, 4.5 parts of cumene, 1.5 parts of triallyl isocyanurate, 20 parts of epoxidized soybean oil, 8 parts of tributyl citrate, 12 parts of microencapsulated red phosphorus, 10 parts of melamine cyanurate, Ca 4 parts of / Zn composite stabilizer, 0.5 parts of vinyltriethoxysilane;

[0021] Wherein, the preparation method of modified calcium carbonate is: take mass fraction and be 25wt% calcium hydroxide aqueous solution, be warming up to 40 ℃,...

Embodiment 2

[0024] A rubber insulation material for rubber-sheathed power cables with a rated voltage above 35kV, the raw materials of which include ter404490 parts by weight, 30 parts of methyl vinyl silicone rubber, 30 parts of ethylene-butylene elastomer, 2 parts of paraffin wax 15 parts of paraffin oil, 1 part of anti-aging agent MB, 2642 parts of anti-aging agent, 4 parts of zinc oxide, 1.5 parts of stearic acid, 15 parts of modified calcium carbonate with a particle size of 50nm, 110 parts of modified fine kaolin, 2.5 parts of cumene, 3.5 parts of triallyl isocyanurate, 10 parts of epoxidized soybean oil, 10 parts of tributyl citrate, 8 parts of microencapsulated red phosphorus, 15 parts of melamine cyanurate, Ca 2 parts of / Zn composite stabilizer, 2 parts of vinyltriethoxysilane;

[0025] Wherein, the preparation method of modified calcium carbonate is: take mass fraction and be 15wt% calcium hydroxide aqueous solution, be warmed up to 60 ℃, add the ethanol solution of stearic aci...

Embodiment 3

[0028] A rubber insulating material for rubber-sheathed power cables with a rated voltage above 35kV, the raw materials of which include by weight: ter404475 parts of ethylene-propylene-diene rubber, 38 parts of methyl vinyl silicone rubber, 23 parts of ethylene-butylene elastomer, and 3.5 parts of paraffin wax 12 parts, 12 parts of paraffin oil, 1.7 parts of anti-aging agent MB, 2641.2 parts of anti-aging agent, 7 parts of zinc oxide, 0.8 part of stearic acid, 12 parts of modified calcium carbonate with a particle size of 90nm, 125 parts of modified fine kaolin, over Dicumyl oxide 4 parts, triallyl isocyanurate 2 parts, epoxidized soybean oil 17 parts, tributyl citrate 8.5 parts, microencapsulated red phosphorus 11 parts, melamine cyanurate 11 parts , 3.5 parts of Ca / Zn composite stabilizer, 1 part of vinyltriethoxysilane;

[0029] Wherein, the preparation method of modified calcium carbonate is: take mass fraction and be 23wt% calcium hydroxide aqueous solution, be warming u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com