Natural-fiber-reinforced polypropylene composite material with mildewproof and antimicrobial properties and preparation method thereof

A natural fiber and composite material technology, applied in the field of fiber composite materials, can solve the problems of material mechanical performance degradation, affecting the service life of materials, and unhealthy contacts, so as to reduce hygroscopicity, prolong service life, and improve anti-mildew and antibacterial performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

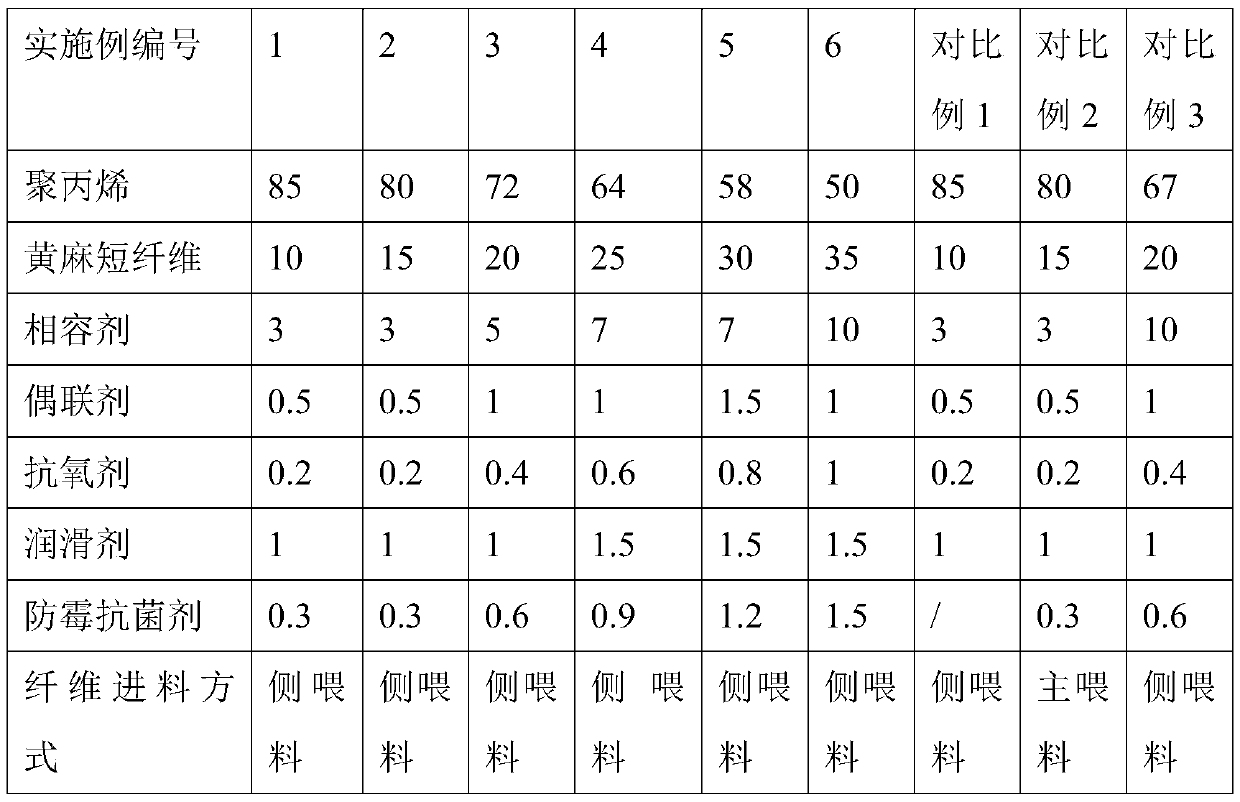

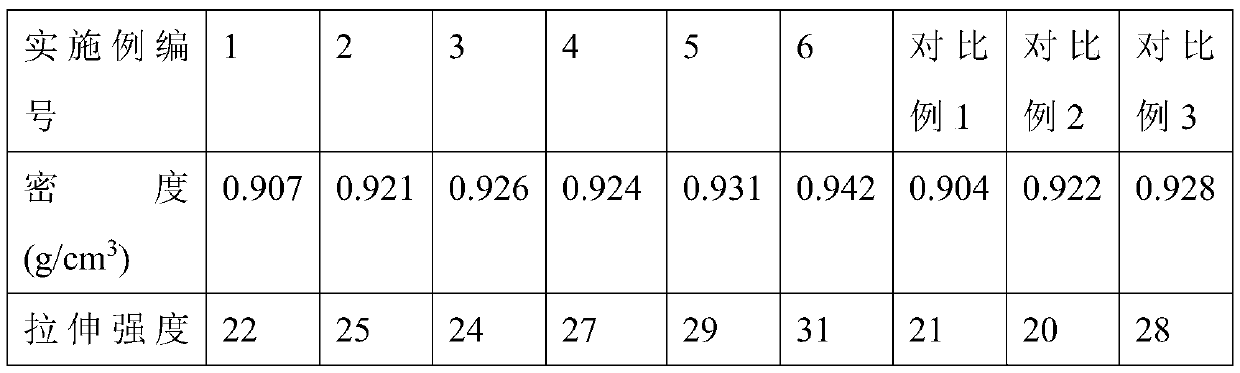

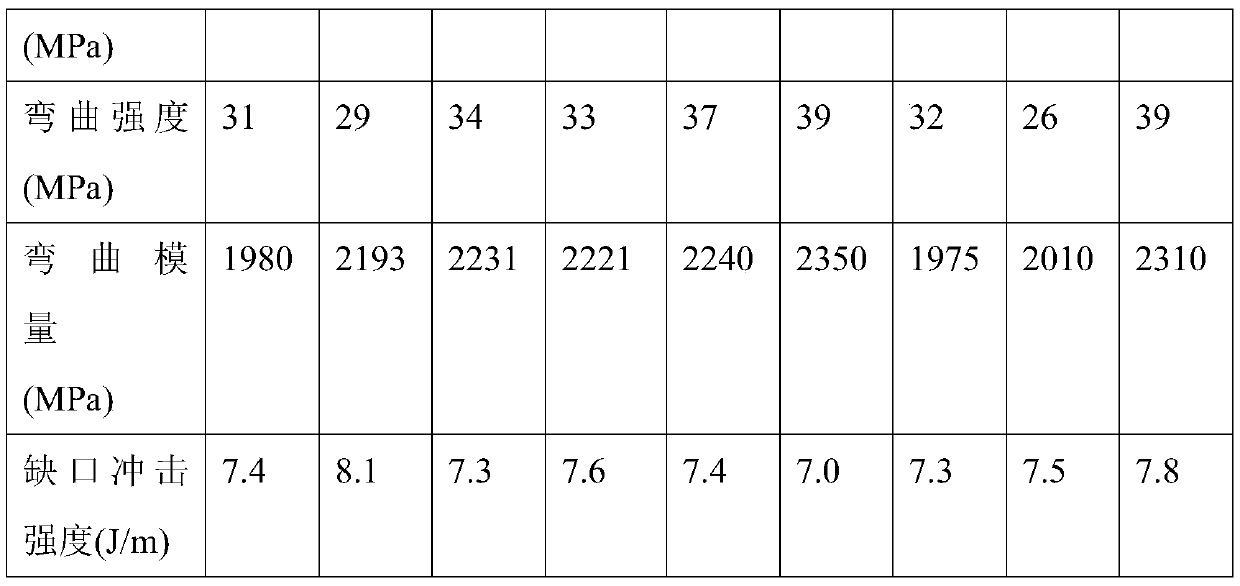

Embodiment 1

[0039] 85 parts of polypropylene; 10 parts of jute fiber; 3 parts of compatibilizer; 0.5 part of coupling agent; 0.2 part of antioxidant; 1 part of lubricant; After the treatment with the compatibilizer and the compatibilizer, the side feed enters the twin-screw extruder and is extruded and pelletized by the extruder with a processing temperature of 160-190°C.

[0040] The polypropylene described in the above example is selected with a melt index of about 15g / 10min; the jute fiber is 3-5mm chopped fiber; the compatibilizer is polypropylene grafted maleic anhydride; the coupling agent is KH550; Oxygen 1010 and antioxidant 168 are compound antioxidants in a mass ratio of 1:2; the lubricant is calcium stearate; the anti-mildew and antibacterial agent is nano-copper oxide. Among them, the extrusion process of each zone of the twin-screw extruder is as follows: the first zone is 160°C, the second zone is 170°C, the third zone is 180-190°C, and the fourth zone is 170°C.

Embodiment 2

[0042] 80 parts of polypropylene; 15 parts of jute fiber; 3 parts of compatibilizer; 0.5 part of coupling agent; 0.2 part of antioxidant; 1 part of lubricant; After the treatment with the compatibilizer and the compatibilizer, the side feed enters the twin-screw extruder and is extruded and pelletized by the extruder with a processing temperature of 160-190°C.

[0043] The polypropylene described in the above example is selected with a melt index of about 15g / 10min; the jute fiber is 3-5mm chopped fiber; the compatibilizer is polypropylene grafted maleic anhydride; the coupling agent is KH550; Oxygen 1010 and antioxidant 168 are compound antioxidants in a mass ratio of 1:2; the lubricant is calcium stearate; the anti-mildew and antibacterial agent is nano-copper oxide. Among them, the extrusion process of each zone of the twin-screw extruder is as follows: the first zone is 160°C, the second zone is 170°C, the third zone is 180-190°C, and the fourth zone is 170°C.

Embodiment 3

[0045] 72 parts of polypropylene; 20 parts of jute fiber; 5 parts of compatibilizer; 1 part of coupling agent; 0.4 part of antioxidant; 1 part of lubricant; 0.6 part of anti-mildew and antibacterial agent; After the treatment with the compatibilizer and the compatibilizer, the side feed enters the twin-screw extruder and is extruded and pelletized by the extruder with a processing temperature of 160-190°C.

[0046] The polypropylene described in the above example is selected with a melt index of about 15g / 10min; the jute fiber is 3-5mm chopped fiber; the compatibilizer is polypropylene grafted maleic anhydride; the coupling agent is KH550; Oxygen 1010 and antioxidant 168 are compound antioxidants in a mass ratio of 1:2; the lubricant is calcium stearate; the anti-mildew and antibacterial agent is nano-copper oxide. Among them, the extrusion process of each zone of the twin-screw extruder is as follows: the first zone is 160°C, the second zone is 170°C, the third zone is 180-190°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com