Novel polypropylene composite resin composition for automobile

A composite resin and polypropylene technology, which is applied in the field of automotive materials, can solve the problems of difficulty in balancing strength and impact properties, and difficulty in interchangeability of materials for different parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

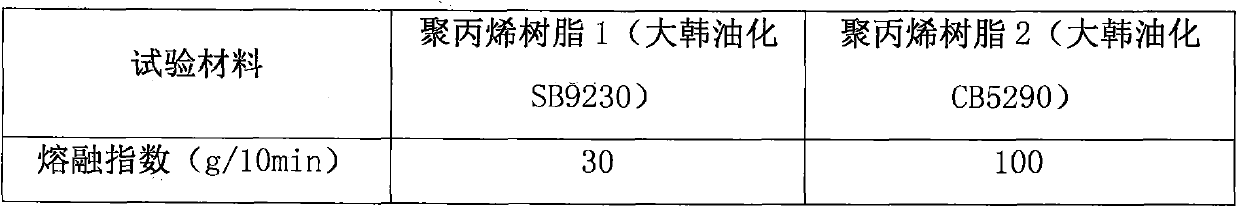

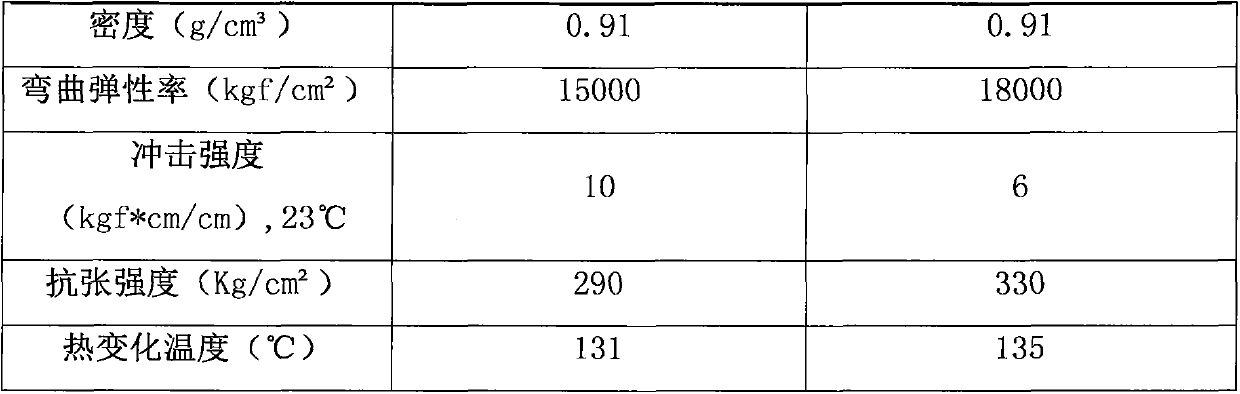

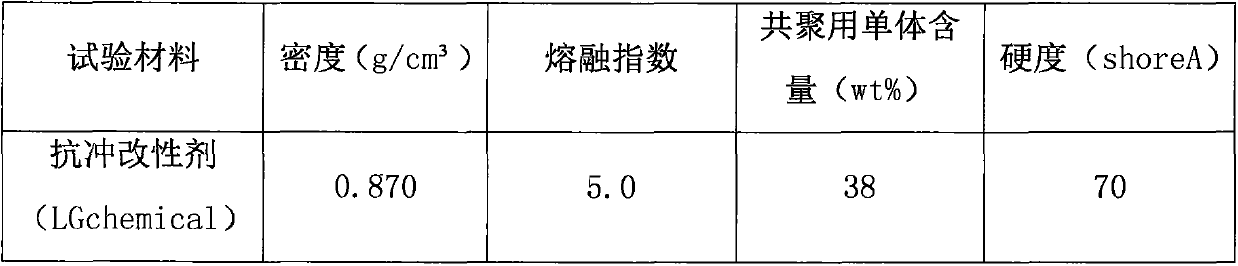

Method used

Image

Examples

example 1~3 and comparative example 1~3

[0051] Table five

[0052] composition

Example 1

Example 2

Example 3

Comparative example 1

Comparative example 2

Comparative example 3

65

30

65

65

65

65

35

whiskers

3

3

2

10

20

17

17

18

20

10

impact enhancer

15

15

15

15

15

15

[0053] Table six

[0054]

[0055] From the results of physical properties in Table 6 above, Example 1 using part of the whiskers has better flexural modulus and heat resistance than Comparative Example 1 using only talc. From Examples 1 to 3, it can be seen that in materials using highly crystalline polypropylene resin materials, the difference in shrinkage in the MD (flow direction / TD (vertical flow direction) direction can be minimized by adjusting the weight ratio of whiskers and talc, and Optimum b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com