Catalytic synthesis method of N-substituted ethanol amine compound

A technology for amine compounds and ethanolamines, which is applied in the field of catalytic synthesis of N-substituted ethanolamine compounds, can solve the problems of unfavorable purification, product separation, and high preparation costs, and achieves easy industrial scale-up production, mild reaction conditions, and specific surface area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

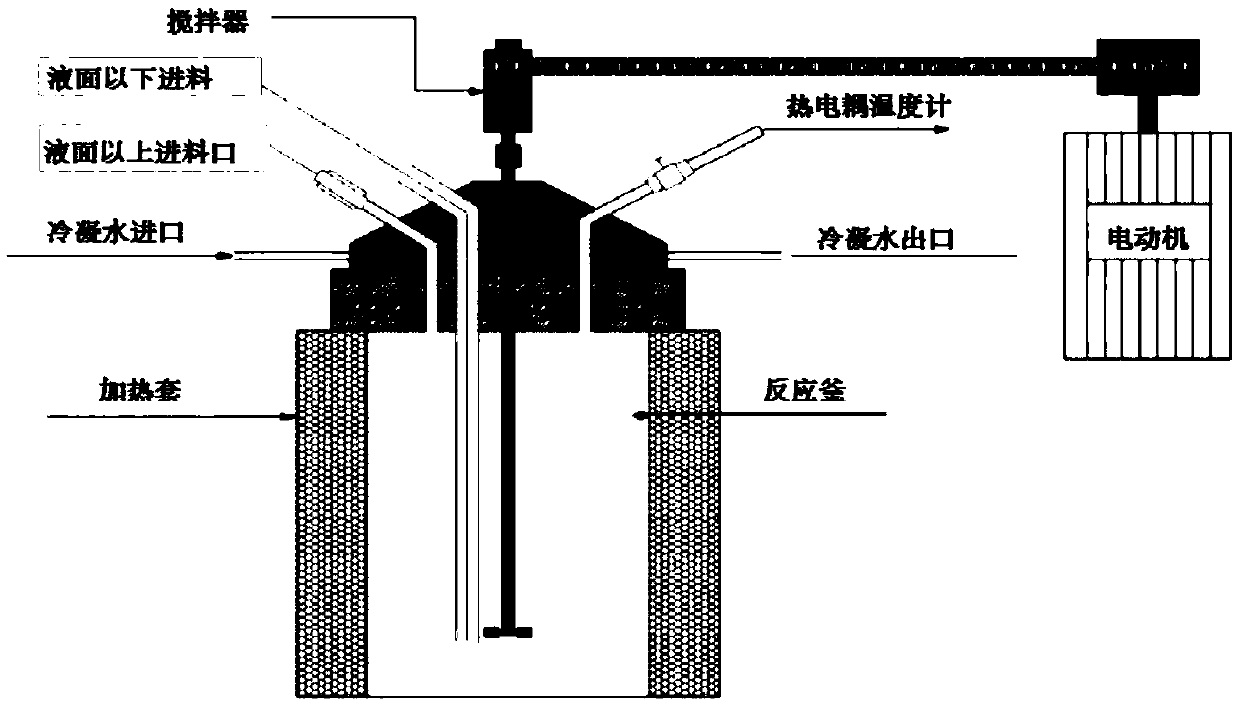

Method used

Image

Examples

Embodiment 1

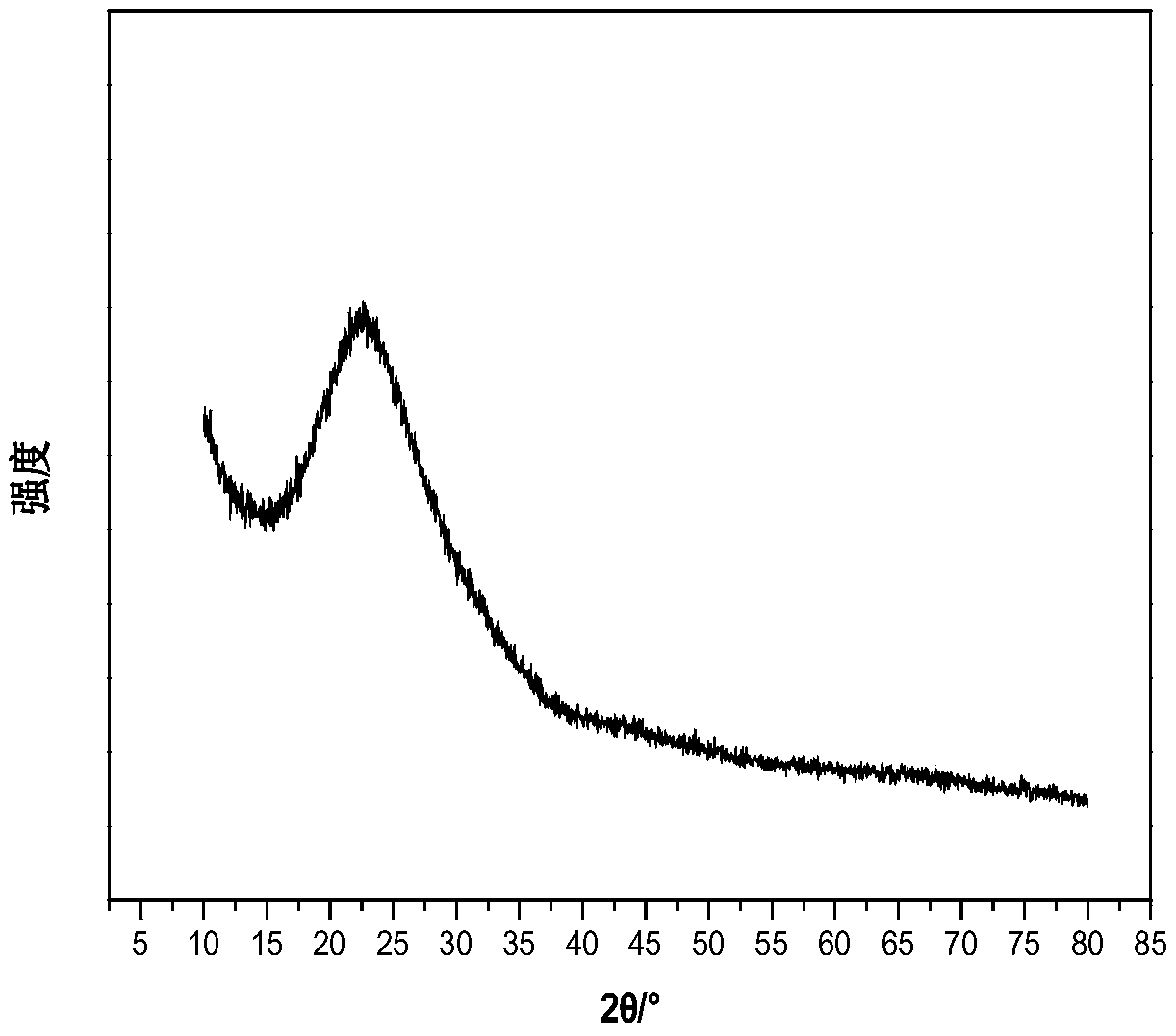

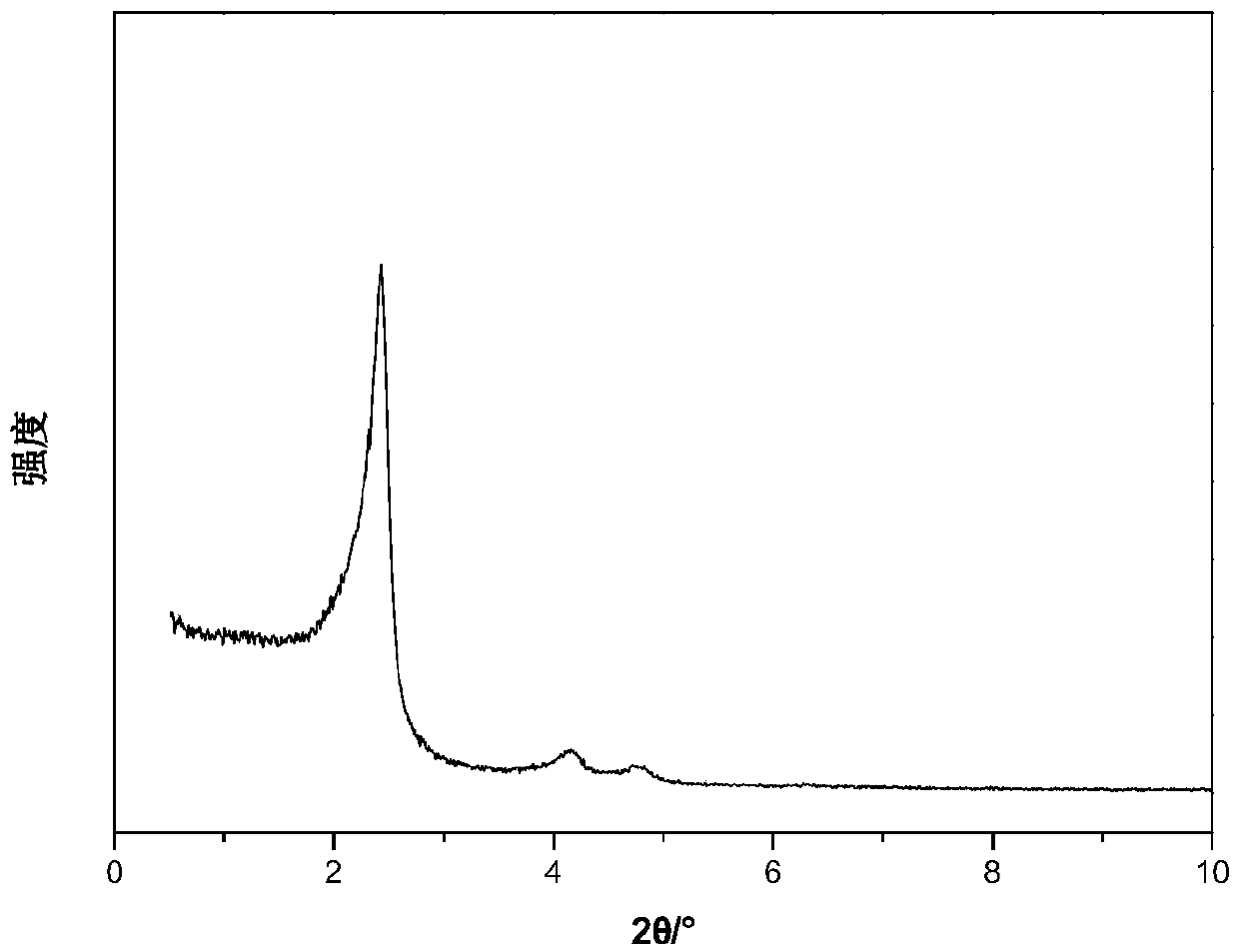

[0031] Preparation of Ti-MCM-41 molecular sieve:

[0032] Weigh 2.67g of sodium hydroxide and 5.94g of cetyltrimethylammonium bromide (CTAB) into 147g of deionized water, and stir vigorously to obtain a colorless transparent solution. Then weigh 14.45 g of tetraethyl silicate (TEOS) and add it dropwise into the above solution, stirring while adding dropwise. After stirring vigorously for 5 hours, use 1.0 mol / L sulfuric acid to adjust the pH of the solution to 9.0. At this time, a large amount of white precipitates are produced in the reaction solution; then weigh 0.657 g of isopropyl titanate and add 15 mL of water to form a solution, Add it dropwise to the above reaction solution, and stir vigorously for 5 hours at a temperature of 20°C to obtain a gel, then transfer the obtained gel to a stainless steel hydrothermal reaction kettle, crystallize at 100°C for 48 hours, and then Filtered, washed with deionized water, and dried at 80°C. After drying, grind the blocky white sol...

Embodiment 2

[0036] Preparation of Ti-MCM-41 molecular sieve:

[0037]The amount of isopropyl titanate in Example 1 was changed to 0.9865g, the sulfuric acid concentration was changed to 0.8mol / l, the crystallization time was changed to 24h, the heating rate was changed to 10°C / min, and the calcination temperature was changed to 600°C. The calcination time was changed to 5h. Others are the same as embodiment 1. 2.2g of Ti-MCM-41 molecular sieve catalyst was prepared, which has a mesoporous structure as detected by XRD, in which the molar ratio of Si:Ti is 1:0.05, and the specific surface area is 869.03m2 as detected by nitrogen adsorption and desorption. 2 / g.

[0038] Ti-MCM-41 molecular sieve catalyst catalyzes the reaction of dimethylamine and ethylene oxide:

[0039] The reaction adopts a high-pressure reactor reactor, and dimethylamine (78.89g, 1.75mol) is mixed with ethylene oxide (22.03g, 0.5mol), and the catalyst 1.0g prepared above is mixed at a reaction temperature of 140°C an...

Embodiment 3

[0041] Preparation of Ti-MCM-41 molecular sieve:

[0042] Change the mass of isopropyl titanate in Example 1 to 1.973g, the sulfuric acid concentration to 0.6mol / l, the crystallization time to 36h, the heating rate to 12°C / min, and the calcination temperature to 650°C, The calcination time was changed to 7h. Others are the same as in Example 1, and 2.1 g of Ti-MCM-41 molecular sieve catalysts are obtained, which has a mesoporous structure as detected by XRD, wherein, the molar ratio of Si:Ti is 1:0.1, and the specific surface area is 681.95 m by nitrogen adsorption and desorption detection. 2 / g.

[0043] Ti-MCM-41 molecular sieve catalyst catalyzes the reaction of aniline and phenyloxirane:

[0044] The reaction adopts a high-pressure reactor reactor, aniline (162.98g, 1.75molmol) is mixed with phenyloxirane (60.08g, 0.5mol), and the catalyst 0.2g prepared above is mixed at a reaction temperature of 160°C and a reaction pressure of The reaction was carried out under the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com