Manganese ore slag foamed rare earth ceramic profile and preparation method thereof

A technology of manganese slag and ceramic type, applied in the field of manganese slag foamed rare earth ceramic profiles and its preparation, to achieve the effect of hard strength, no secondary pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

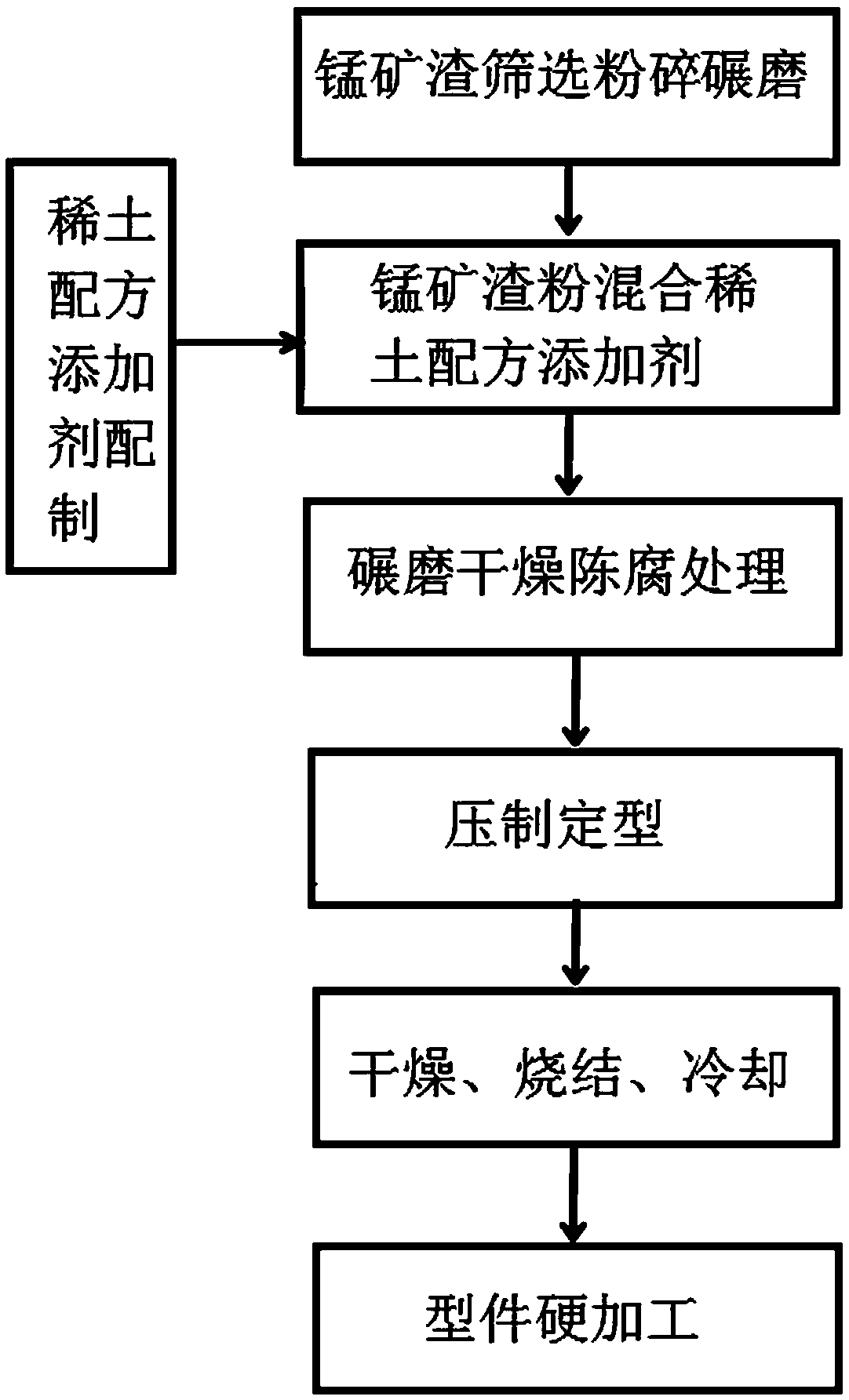

Method used

Image

Examples

Embodiment 1

[0029]The composition weight ratio of each raw material of the manganese slag foamed rare earth ceramic profile in this embodiment is: manganese slag powder: rare earth formula additive = 30:35; the composition weight ratio of the rare earth formula additive is: solid waste material powder: rare earth powder = 50 : 60; The composition weight ratio of the solid waste material powder is: CaCo 3 : SiO 2 : NaCO 3 :B 2 o 3 :K 2 O=20:30:19:5:3; the composition weight ratio of the rare earth powder is: Y 2 o 3 : La 2 o 3 : Sm 2 o 3 : Yb 2 o 3 : Fe 2 o 3 =50:40:15:3:30.

[0030] The preparation method of the manganese slag foamed rare earth ceramic profiles in this embodiment is as follows: firstly select the manganese slag and then remove superficial debris or floating soil to obtain relatively clean manganese slag, and then screen out stones or other debris; The manganese slag is pulverized twice and enters a ball mill to be ground into manganese slag powder, the mang...

Embodiment 2

[0032] The composition weight ratio of each raw material of the manganese slag foamed rare earth ceramic profile in this embodiment is: manganese slag powder: rare earth formula additive = 85: 15; the composition weight ratio of the rare earth formula additive is: solid waste material powder: rare earth powder = 90 : 10; The composition weight ratio of the solid waste material powder is: CaCo 3 : SiO 2 : NaCO 3 :B 2 o 3 :K 2 O=40:60:6:15:10; the composition weight ratio of the rare earth powder is: Y 2 o 3 : La 2 o 3 : Sm 2 o 3 : Yb 2 o 3 : Fe 2 o 3 =30:60:5:10:15.

[0033] The preparation method of the manganese slag foamed rare earth ceramic profile in this embodiment is as follows: firstly select the manganese slag and then remove superficial debris or floating soil to obtain relatively clean manganese slag, and then screen out stones or other debris; After the manganese slag is pulverized for 4 times, enter the ball mill to grind into manganese slag powder, ...

Embodiment 3

[0035] The composition weight ratio of each raw material of the manganese slag foamed rare earth ceramic profile in this embodiment is: manganese slag powder: rare earth formula additive = 57:25; the composition weight ratio of the rare earth formula additive is: solid waste material powder: rare earth powder = 70 : 35; The composition weight ratio of the solid waste material powder is: CaCo 3 : SiO 2 : NaCO 3 :B 2 o 3 :K 2 O=30:45:12:10:6; the composition weight ratio of the rare earth powder is: Y 2 o 3 : La 2 o 3 : Sm 2 o 3 : Yb 2 o 3 : Fe 2 o 3 =40:50:10:6:22.

[0036] The preparation method of the manganese slag foamed rare earth ceramic profile in this embodiment is as follows: firstly select the manganese slag and then remove superficial debris or floating soil to obtain relatively clean manganese slag, and then screen out stones or other debris; After the manganese slag is pulverized for 3 times, enter the ball mill to grind into manganese slag powder, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com