Spot welding electrode

A spot welding electrode and tungsten alloy technology, applied in the direction of electrode characteristics, welding equipment, welding medium, etc., can solve the problems of welding electrode wear, cost increase, energy consumption increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

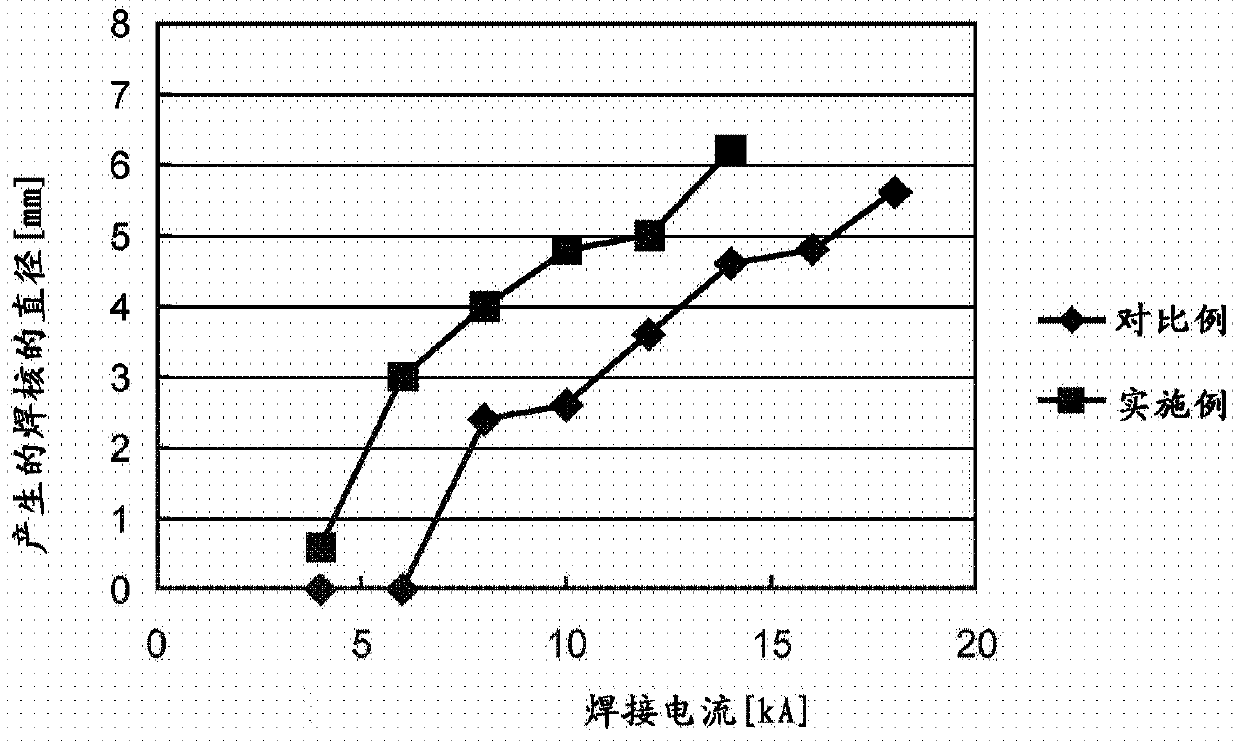

Examples

Embodiment Construction

[0016] Hereinafter, embodiments of the present invention will be described in detail.

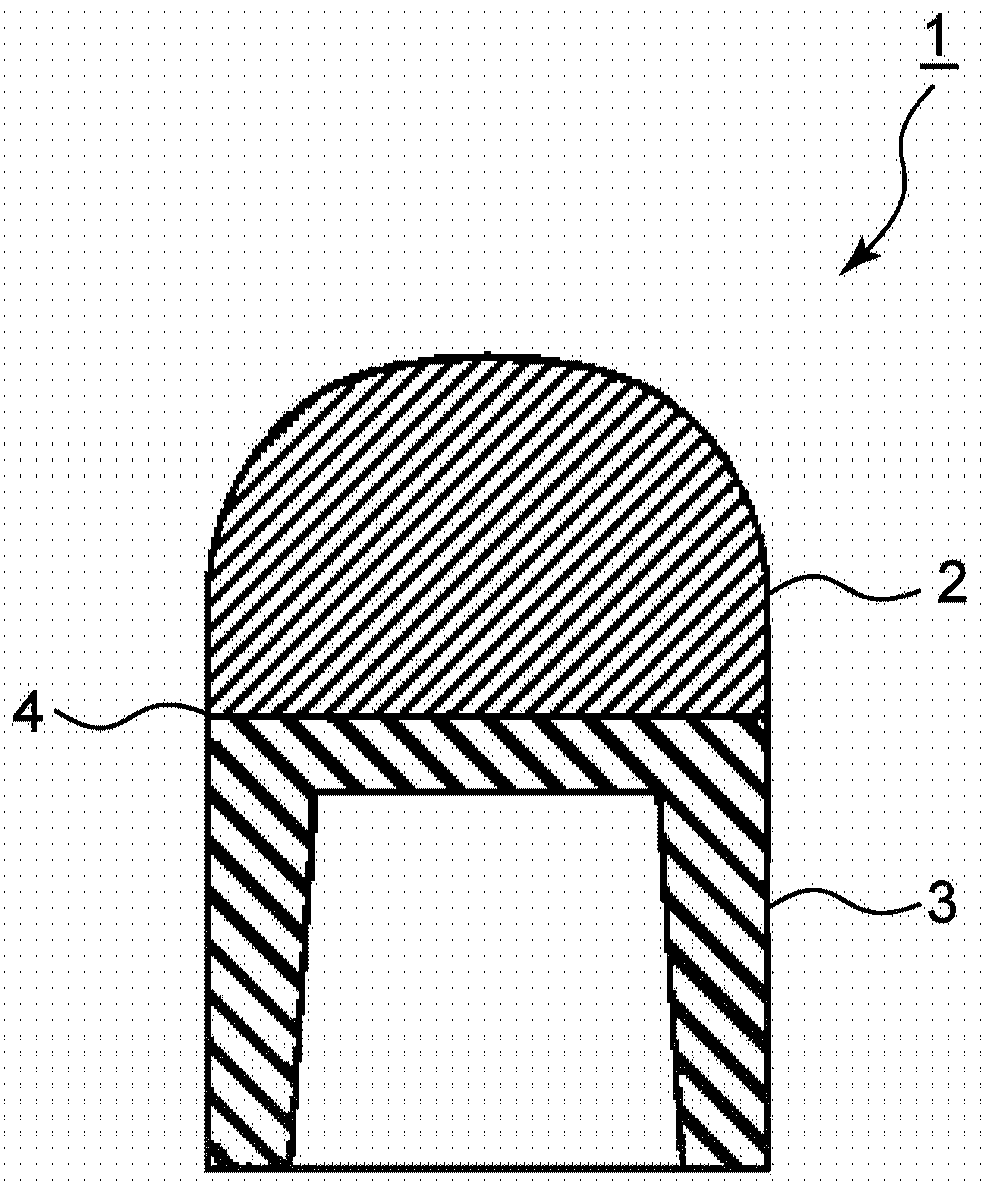

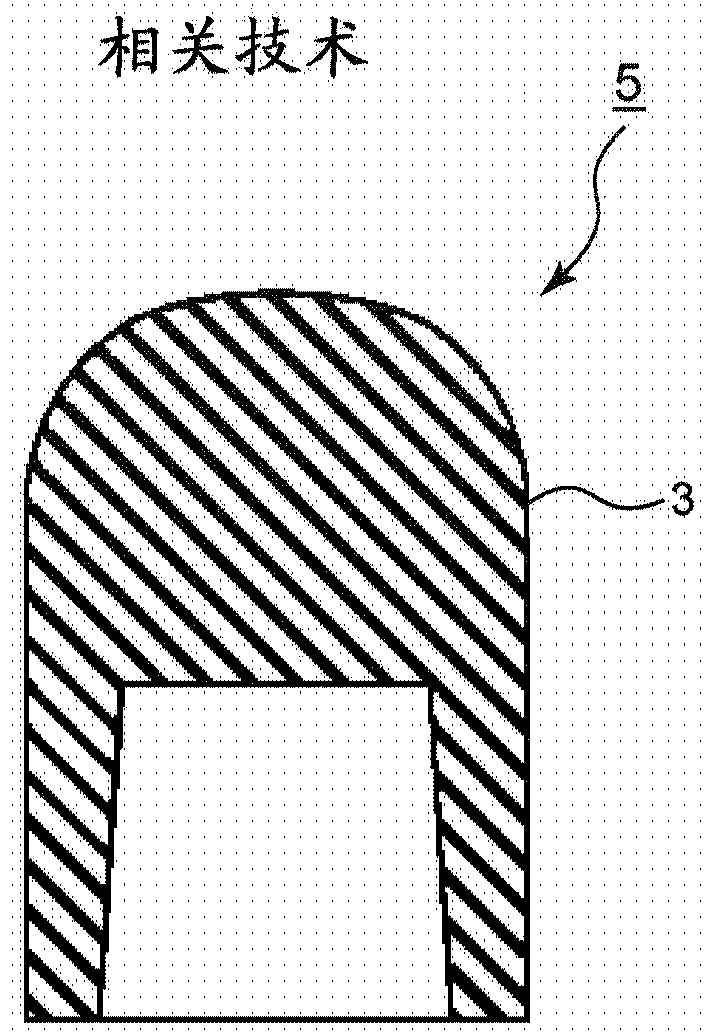

[0017] Embodiments of the present invention relate to a spot welding electrode comprising a copper alloy and a sintered tungsten alloy.

[0018] The copper alloy contained in the spot welding electrode of the embodiment of the present invention is an alloy containing copper (Cu) as a main metal. The elements other than copper contained in the copper alloy are not limited to specific elements. Examples of elements other than copper contained in the copper alloy include chromium (Cr), zirconium (Zr), nickel (Ni), silicon (Si), zinc (Zn), and beryllium (Be). From the viewpoint of preventing deformation of the electrode, the copper alloy preferably contains chromium and / or beryllium. The copper alloy may contain two or more of the above elements as elements other than copper.

[0019] The sintered tungsten alloy contained in the spot welding electrode of the embodiment of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com