A kind of silver or aluminum spectacle frame low-temperature welding method

A low-temperature welding and eyeglass frame technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high welding difficulty, poor welding quality, low welding strength, etc., to improve welding quality, reduce welding difficulty, welding low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

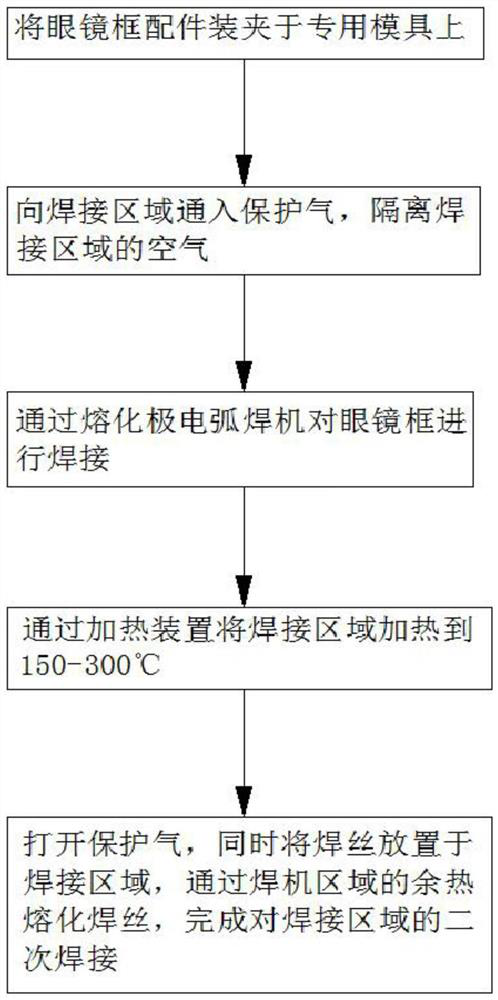

[0032] This embodiment is a basic embodiment of the present invention. The main material of the spectacle frame to be welded is silver. It discloses a low-temperature welding method for spectacle frames. It should be noted that the spectacle frame described in this embodiment uses silver as the main material. , which includes the following steps:

[0033] A. Clamp the spectacle accessories that have been processed in the early stage such as grinding and polishing to the corresponding position on the special mold, and adjust the position of the spectacle accessories so that the position between each spectacle accessory is in the best welding position;

[0034] B. Turn on the shielding gas delivery device and continuously feed pure argon gas into the welding area as shielding gas, so as to isolate the air in the welding area and form a protective layer for the welding area;

[0035] C. After 3 seconds of starting to deliver the shielding gas, send the silver welding wire with a ...

Embodiment 2

[0040] This embodiment, as another preferred embodiment of the present invention, discloses a low-temperature welding method for spectacle frames. It should be pointed out that the spectacle frame described in this embodiment is made of silver as the main material, and the welding method includes the following steps :

[0041] A. Clamp the spectacle accessories that have been processed in the early stage such as grinding and polishing to the corresponding position on the special mold, and adjust the position of the spectacle accessories so that the position between each spectacle accessory is in the best welding position;

[0042] B. Turn on the shielding gas delivery device and continuously feed pure helium gas into the welding area as shielding gas, so as to isolate the air in the welding area and form a protective layer for the welding area;

[0043] C. After 4 seconds of starting to deliver the shielding gas, the tin-based welding wire with a diameter of 0.5mm is delivered...

Embodiment 3

[0048] This embodiment, as another preferred embodiment of the present invention, discloses a low-temperature welding method for spectacle frames. It should be pointed out that the spectacle frame described in this embodiment is made of silver as the main material, and the welding method includes the following steps :

[0049] A. Clamp the spectacle accessories that have been processed in the early stage such as grinding and polishing to the corresponding position on the special mold, and adjust the position of the spectacle accessories so that the position between each spectacle accessory is in the best welding position;

[0050] B. Turn on the shielding gas delivery device and continuously feed the mixed gas of argon and hydrogen into the welding area as the shielding gas. According to the actual production conditions such as the activity of the welding wire and the main material, and the reaction temperature, it is determined that the argon gas accounts for 85% of the total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com