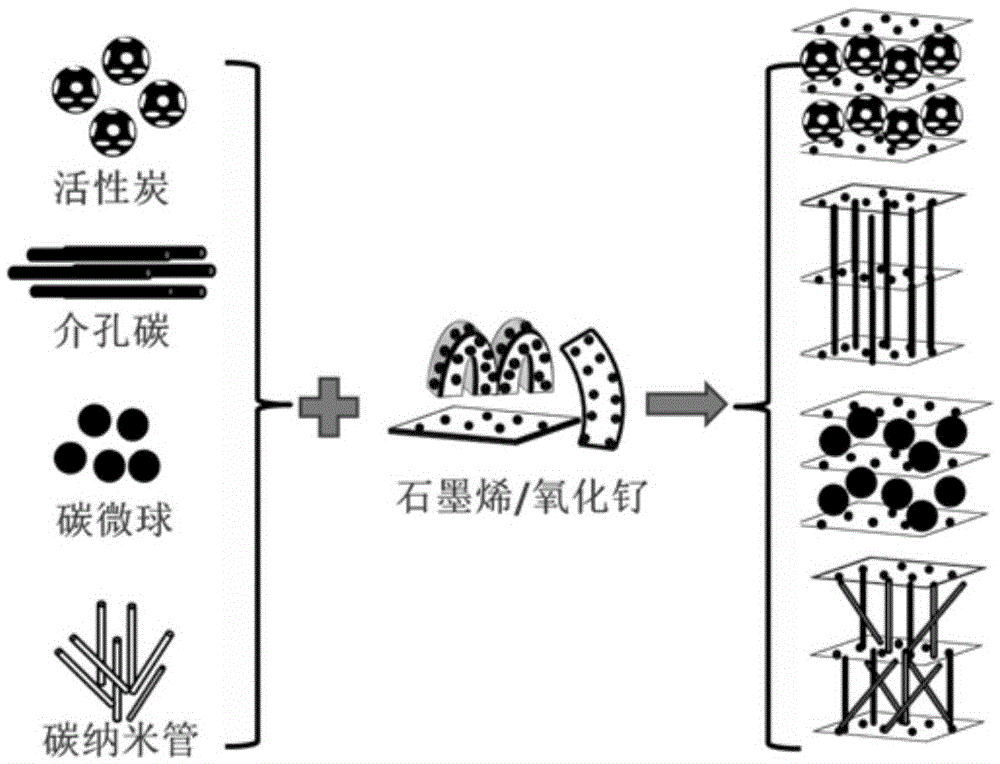

Preparation method and application of chemically-modified carbon material/graphene/RuO2 ternary composite material

A technology of chemical modification and composite materials, which is applied in the field of preparation of chemically modified carbon materials/graphene/RuO2 ternary composite materials, which can solve problems such as the collapse of ruthenium oxide crystal structure, the reduction of electrochemical performance, and the pulverization of materials. Achieve excellent stability, improve electrochemical performance, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Put carbon dioxide nanotubes, graphite oxide, and ruthenium chloride into the hydrothermal reaction kettle according to a certain mass ratio (1:3:36), place them in an electric blast drying oven at 200°C for 15 hours, pour off the supernatant, and centrifuge repeatedly , washed with water to obtain the corresponding composite material powder, and annealed at 190 ° C for 3 hours.

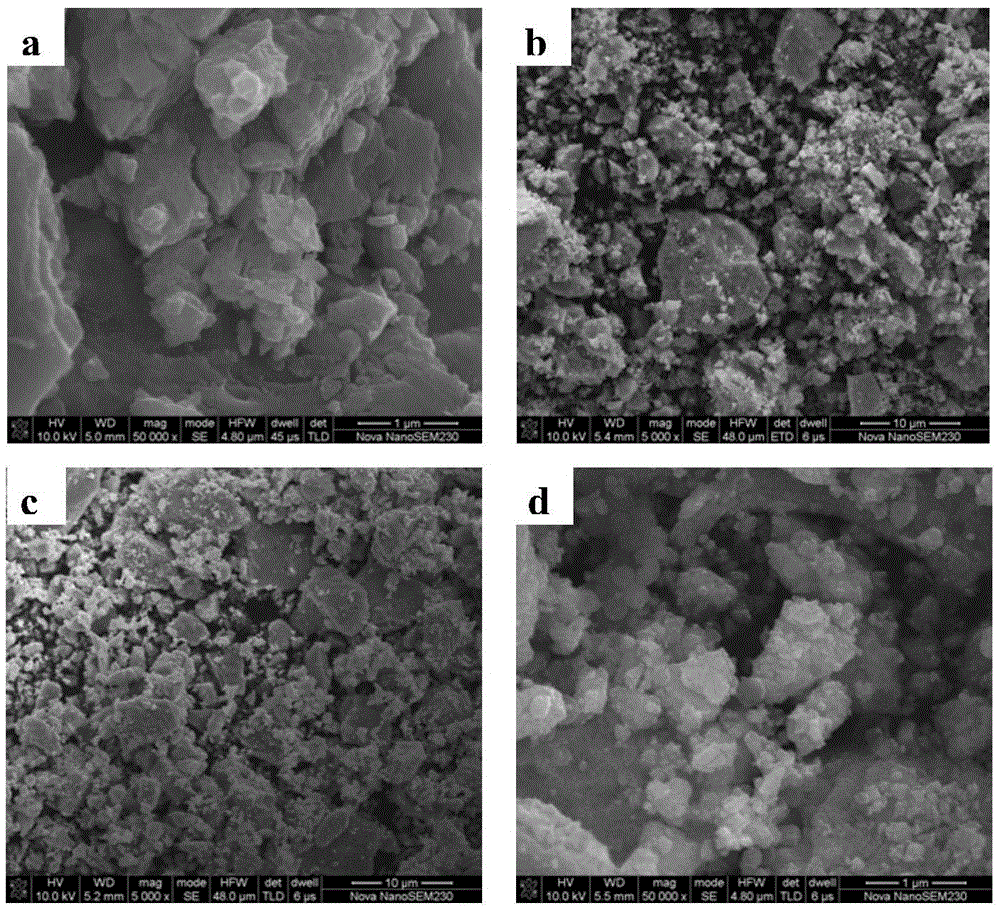

[0050] figure 2 a is the carbon nanotube / reduced graphene oxide / RuO that embodiment 1 makes 2 SEM photographs of composite materials. From this figure, it can be seen that the addition of reduced graphene oxide introduces a multilayer wrinkled surface structure, and the RuO 2 The uniform dispersion on the larger substrate surface it provides.

Embodiment 2

[0052] Put oxidized activated carbon, graphite oxide, and ruthenium chloride into the hydrothermal reaction kettle according to a certain mass ratio (1:4:36), place it in an electric blast drying oven at 200°C for 15 hours, pour it to remove the supernatant, and repeat centrifugation and water washing The corresponding composite material powder was obtained and annealed at 190°C for 3h.

[0053] figure 2 B is activated carbon / reduced graphene oxide / RuO that embodiment 2 makes 2 SEM photographs of composite materials. It can be seen from the figure that there are many cracks and pores on the overall surface of the composite material, showing a loose state.

Embodiment 3

[0055] Put mesoporous carbon oxide, graphite oxide, and ruthenium chloride in a certain mass ratio (1:3:40) into the hydrothermal reactor, place it in an electric blast drying oven at 200°C for 15 hours, pour it to remove the supernatant, and centrifuge repeatedly , washed with water to obtain the corresponding composite material powder, and annealed at 200 ° C for 3 hours.

[0056] figure 2 C is the mesoporous carbon / reduced graphene oxide / RuO that embodiment 3 makes 2 SEM photographs of composite materials. It can be seen from the figure that oxygen-containing carbon materials and RuO 2 The combination is very tight, showing a tendency of uniform mixing and dispersion, RuO 2 In situ, it forms a honeycomb film on the surface of the carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com