A kind of alcoholysis-resistant PPA composite material and processing method thereof for automobile

A composite material and alcoholysis-resistant technology, which is applied in the field of alcoholysis-resistant PPA composite materials for automobiles and its processing, and achieves the effects of no change in the surface of the sample, high heat resistance, and good surface of the sample

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

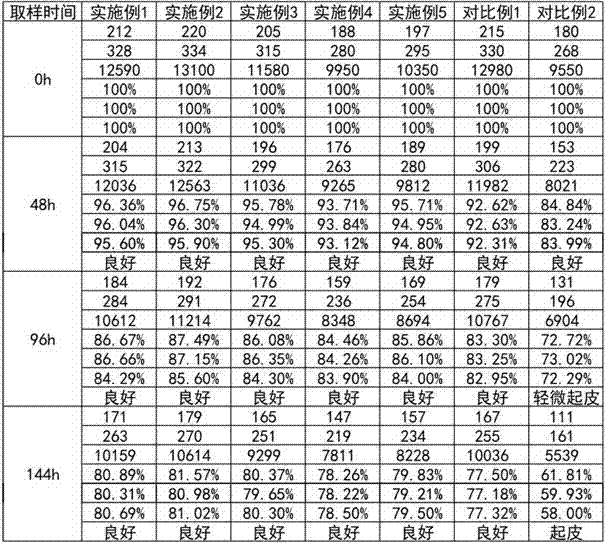

Examples

Embodiment 1

[0028] An alcoholysis-resistant PPA composite material for automobiles is composed of the following components by weight percentage: 58% of PPA, 40% of pretreated glass fiber, 0.5% of nucleating agent, 1.1% of auxiliary agent, and 0.4% of heat stabilizer.

[0029] The processing method of described automobile with alcoholysis resistant PPA composite material, comprises the steps:

[0030] (1) Glass fiber is pretreated, including the following steps:

[0031] a. First, mix the silane coupling agent, water and ethanol to prepare a mixed solution. The volume ratio of ethanol, water and silane coupling agent is ethanol: water: silane coupling agent = 30:8:0.8, in which silane coupling agent The joint agent is 3-aminopropyltriethoxysilane;

[0032] b. Immerse the ordinary continuous glass fiber in the mixed solution, ultrasonically treat it for 20 minutes, the frequency is 70KHz, and let it stand for 50 minutes; then mechanically vibrate for 40 minutes, the frequency is 600Hz and ...

Embodiment 2

[0040] An alcoholysis-resistant PPA composite material for automobiles is composed of the following components by weight percentage: 58.1% of PPA, 40% of pretreated glass fiber, 0.4% of nucleating agent, 1% of auxiliary agent, and 0.5% of heat stabilizer.

[0041] The processing method of described automobile with alcoholysis resistant PPA composite material, comprises the steps:

[0042] (1) Glass fiber is pretreated, including the following steps:

[0043] a. First, mix silane coupling agent, water and ethanol to prepare a mixed solution. The volume ratio of ethanol, water and silane coupling agent is ethanol: water: silane coupling agent = 35: 10: 0.5, of which silane coupling agent The joint agent is N-2-aminoethyl-3-aminopropyltrimethoxysilane;

[0044]b. Immerse the ordinary continuous glass fiber in the mixed solution, ultrasonically treat it for 18 minutes, the frequency is 75KHz, and let it stand for 60 minutes; then mechanically vibrate for 50 minutes, the frequency...

Embodiment 3

[0052] An alcoholysis-resistant PPA composite material for automobiles consists of the following components by weight percentage: 58% PPA, 40% pretreated glass fiber, 0.6% nucleating agent, 1% auxiliary agent, and 0.4% heat stabilizer.

[0053] The processing method of described automobile with alcoholysis resistant PPA composite material, comprises the steps:

[0054] (1) Glass fiber is pretreated, including the following steps:

[0055] a. First mix the silane coupling agent, water and ethanol to prepare a mixed solution. The volume ratio of ethanol, water and silane coupling agent is ethanol: water: silane coupling agent = 40:5:1, in which silane coupling agent The coupling agent is diethylenetriaminopropyltrimethoxysilane;

[0056] b. Immerse the ordinary continuous glass fiber in the mixed solution, ultrasonically treat it for 15min, the frequency is 80KHz, and let it stand for 55min; then mechanically vibrate for 60min, the frequency is 550Hz and the amplitude is 1mm; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com