Catalyst-free method for preparing polysiloxane perfluoropolyether

A polysiloxane and perfluoropolyether technology, which is applied in the field of chemical materials and surface treatment of substrates, can solve the problems of low yield of hydrosilylation, easy to form gel, easy to be wiped off, etc., so as to save consumption , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A catalyst-free preparation method for polysiloxane perfluoropolyether, the steps of the method are as follows:

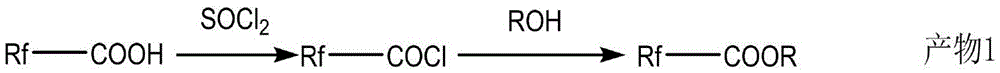

[0027] ⑴Preparation of perfluoropolyether acrylate

[0028] Add excess thionyl chloride dropwise to perfluoropolyether carboxylic acid in a three-necked flask, then add a certain amount of solvent, and react with magnetic stirring at 60-80°C for 4-7 hours. After washing, excess thionyl chloride is distilled off under reduced pressure to obtain perfluoropolyether acid chloride. According to the molar ratio of 1:1-1.5, add perfluoropolyether acid chloride and hydroxyl-containing acrylate compound into a three-necked flask, and react at room temperature for several hours under the protection of nitrogen. Washing, and distilling off excess acrylate compound under reduced pressure to obtain product 1, perfluoropolyether acrylate. The reaction equation is as follows:

[0029]

[0030] Rf is perfluoropolyether: CF 3 CF 2 CF 2 O(CF(CF 3 ) CF 2 O) n , n=1...

example 1

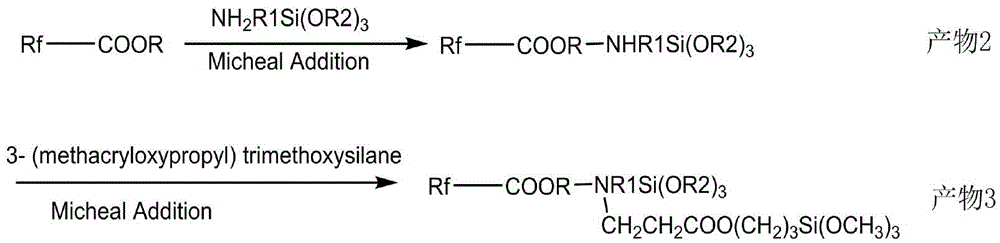

[0046] Synthesis 1. Rf-COOCH 2 C(CH 2 OCOCH 2 CH 2 NH(CH 2 ) 3 Si(OCH 3 ) 3 ) 3

[0047] Under nitrogen protection, PFPE-PETA (3 g, 0.000920 mol) and 3-aminopropyltrimethoxysilane (0.165, 0.000920 mol) were added to a 100 ml three-neck flask equipped with a magnetic stirring rotor, a nitrogen inlet and a reflux condenser. Stir at room temperature for 20 min, then stir at 55°C for 16 h, wash and distill under reduced pressure to obtain a yellow-brown viscous oil (PFPE-PETA-APS-3000).

example 2

[0049] Synthesis 2.

[0050] Rf-COOCH 2 C(CH 2 OCOCH 2 CH 2 N(CH 2 C(CH 3 )COO(CH 2 ) 3 Si(OCH 3 ) 3 )(CH 2 ) 3 Si(OCH 3 ) 3 ) 3

[0051] PFPE-PETA-APS-3000 (1.5 g, 0.000436 mol) was added to a 100 ml three-neck flask equipped with a magnetic stirring rotor, a nitrogen inlet and a reflux condenser under nitrogen protection. Gamma-(methacryloyloxy)propyltrimethoxysilane (0.1083 g, 0.000436 mol) was added dropwise to the flask over 20 min. Stir at room temperature for 30 min, then at 50 °C for 10 h. The peak associated with the secondary amine group was confirmed in FTIR analysis (~1546cm -1 ) to stop the reaction. After washing and reducing pressure, a yellow viscous oil (PFPE-PETA-APS-S3000) was obtained.

PUM

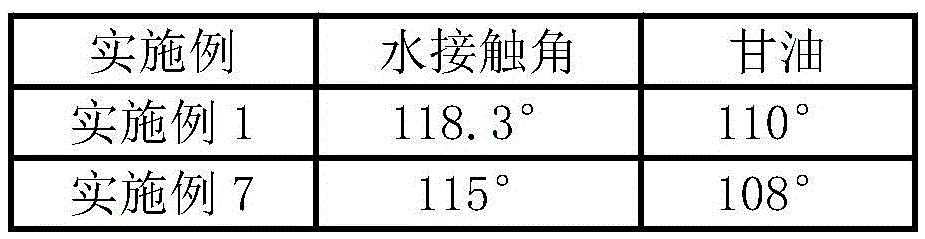

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com