Extrusion die

An extrusion die and die technology, applied in metal extrusion die and other directions, can solve the problems of poor heat dissipation effect and poor durability of the die, and achieve the effect of good protection effect, improved protection effect and improved product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

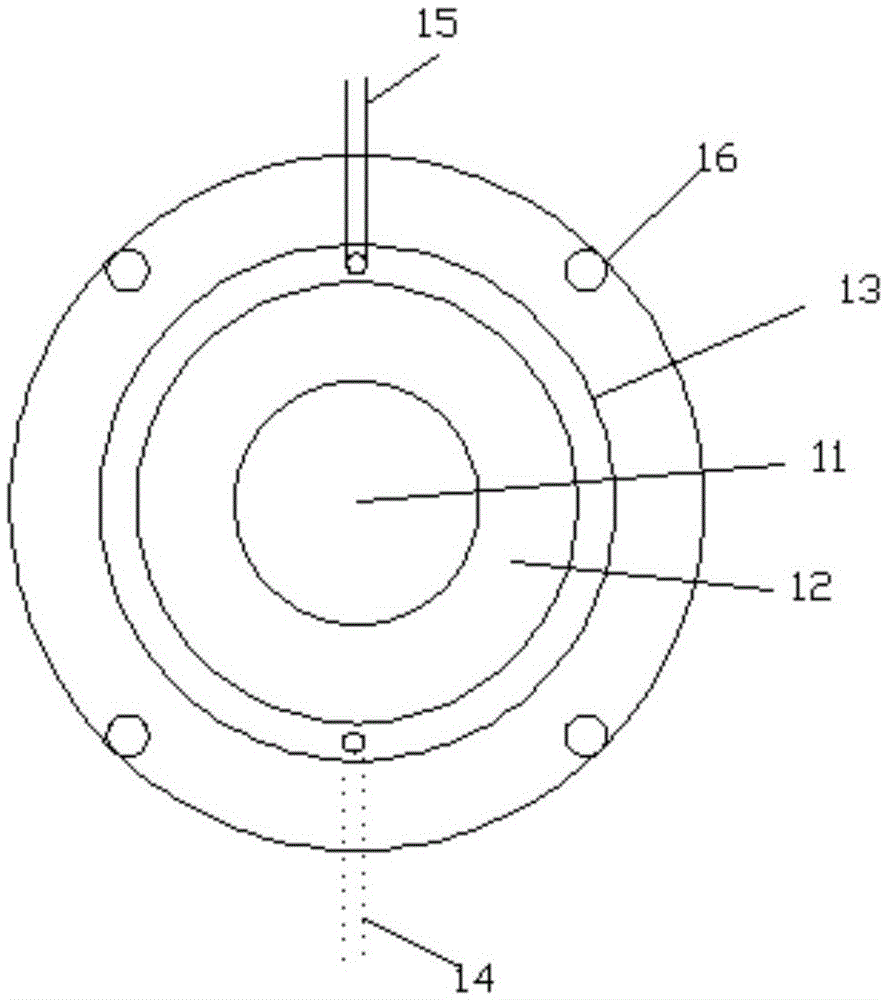

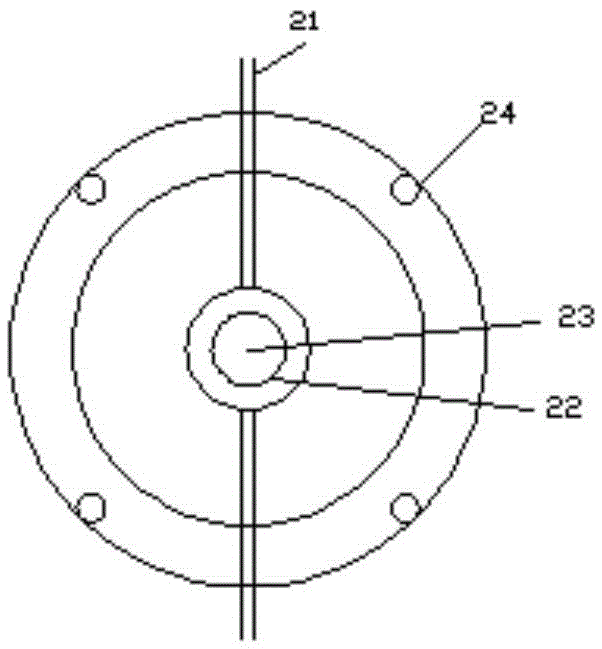

[0027] Below in conjunction with accompanying drawing, this technical scheme is further described as follows:

[0028] Such as Figure 1-5 As shown, the present invention discloses an extrusion die, an extrusion die, comprising a die face 2 and a die pad 1, characterized in that the die pad 1 includes a die hole 11, a die hole effect layer 12 and a cooling interlayer 13. The mold surface 2 is provided with a mold working belt 23, an air guide groove 22 and an air inlet 21; the inert gas enters from the air inlet 21 of the mold surface 2 and flows into the mold through the air guide groove 22 to work Belt 23; the mold working belt 23 and the die hole 11 are circular holes; the cooling interlayer 13 is provided with an inlet pipe 14 and an outlet pipe 15; the inlet pipe 14 is located at the bottom of the mold pad 1, and the outlet pipe 15 is located at the mold pad 1 Top; the water inlet pipe 14 and the water outlet pipe 15 are arranged in parallel and opposite directions; the ...

Embodiment 2

[0030] Select a commercially available similar extrusion die, and conduct a comparative test with the extrusion die in Example 1 of the present invention and the extrusion die in the implementation of CN201510191067.

[0031] 1. Durability test: 500 molds were taken for comparison for 1000 hours.

[0032]

[0033] 2. Product yield test: take 20 molds each, and compare the production of 1000 products

[0034]

[0035] It can be seen that the extrusion die of the present invention can effectively avoid the production of alumina particles, improve the product yield and reduce die loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com