A composite metal hydrogen separation membrane and its preparation method and application

A composite metal and separation membrane technology, which is applied in separation methods, hydrogen separation, semi-permeable membrane separation, etc., can solve the problems of weak bonding strength between porous stainless steel and metal membrane, and achieve good thermal cycle stability, long service life, and combination high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

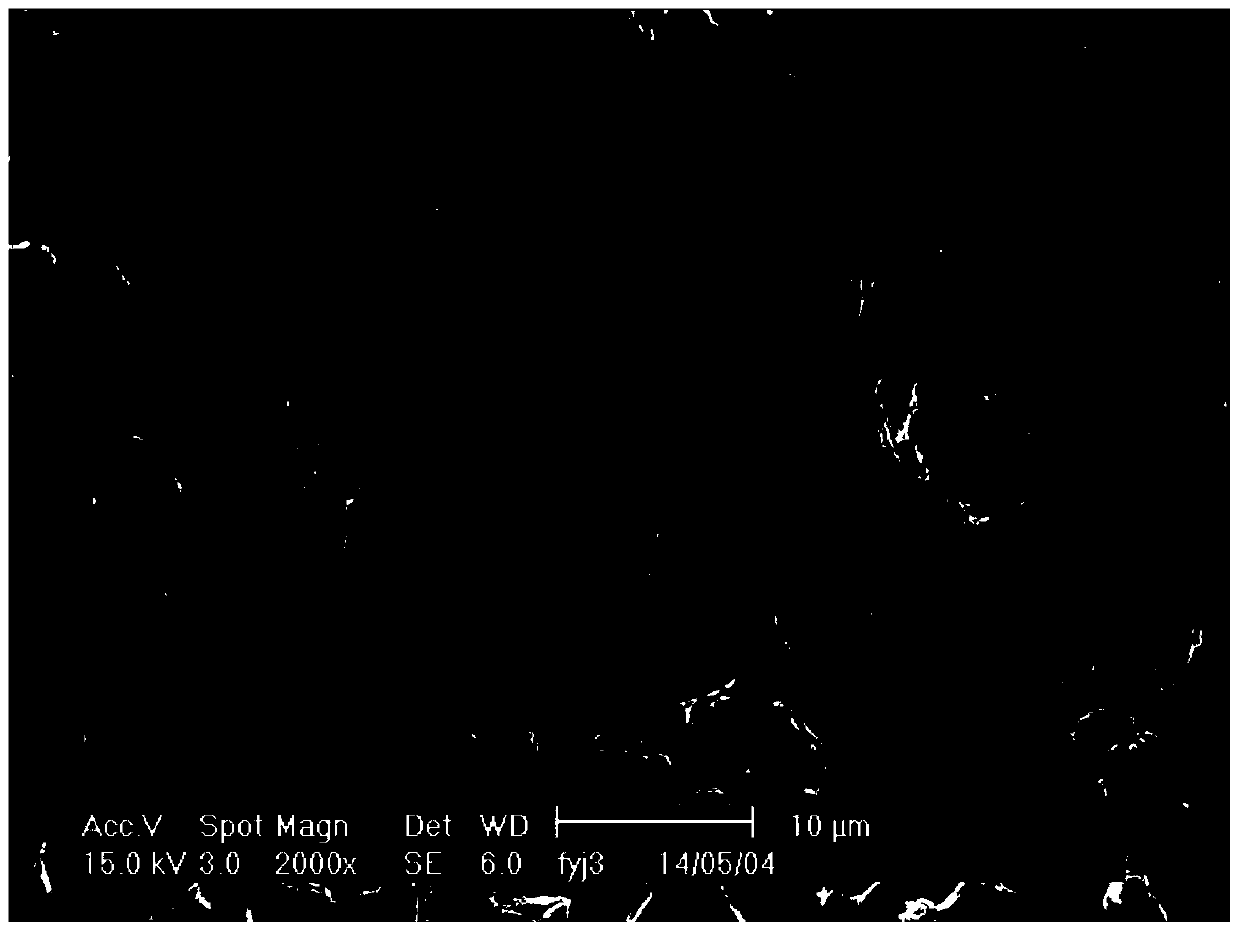

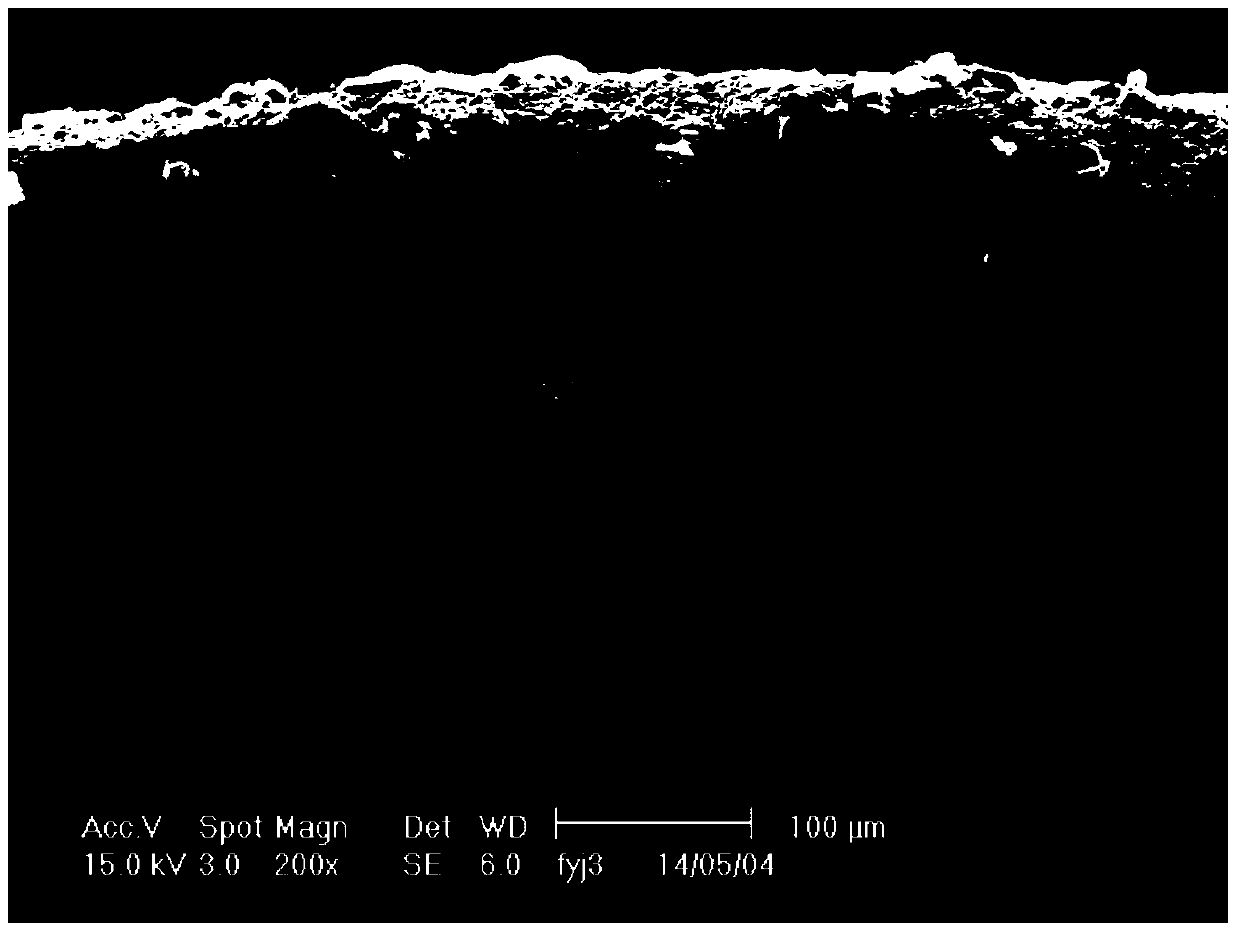

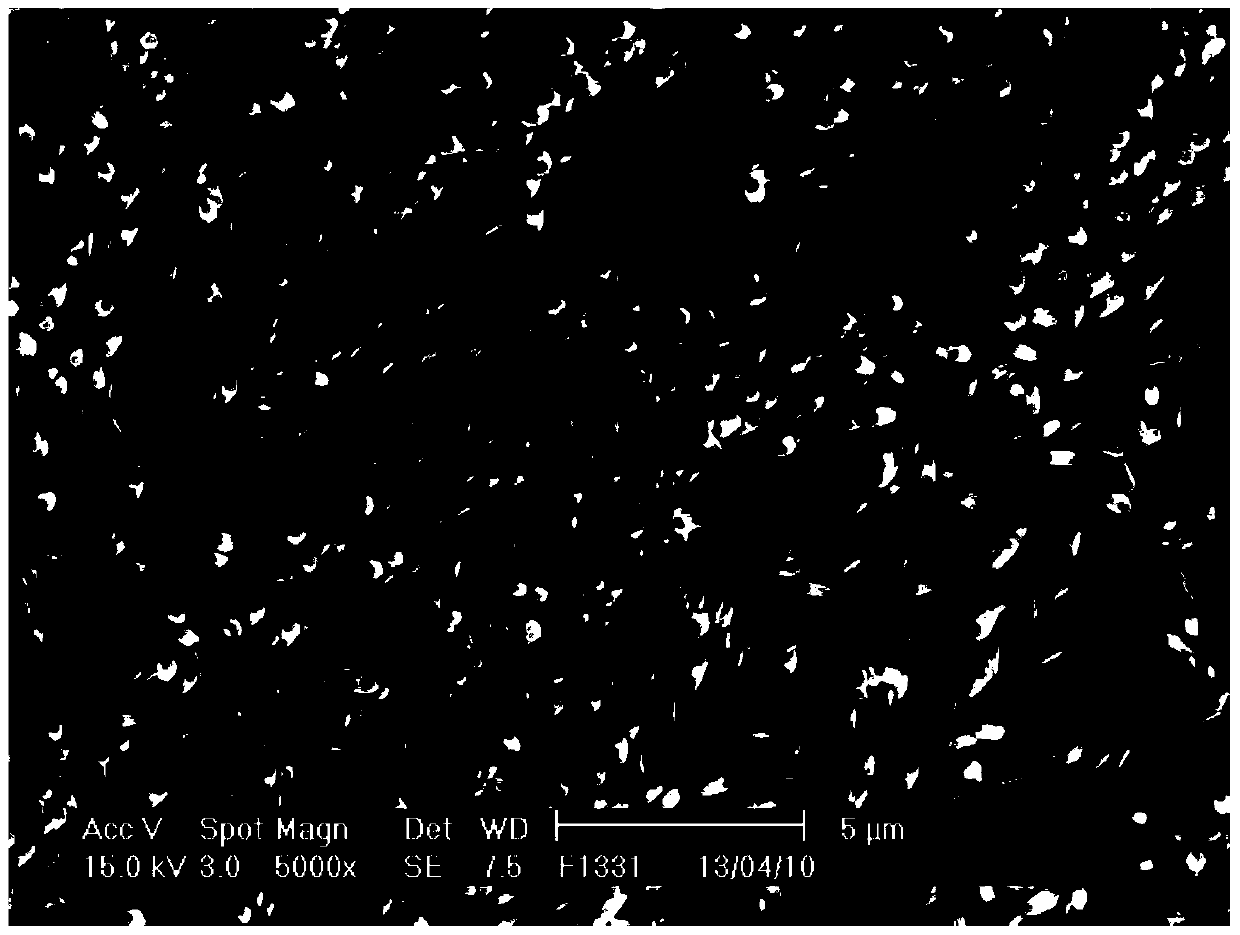

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing a composite metal hydrogen separation membrane, the method comprising the following steps:

[0041] (1) immersing the porous stainless steel in a mixed solution containing a water-soluble zinc salt and hexamethylenetetramine to carry out the first hydrothermal reaction to obtain a porous stainless steel attached with zinc oxide;

[0042](2) The second hydrothermal reaction is carried out by immersing the porous stainless steel with zinc oxide attached obtained in step (1) in an aqueous solution of a water-soluble palladium salt.

[0043] In the present invention, preferably, in the mixed solution, the molar concentration of the water-soluble zinc salt is 0.01-0.2mol / L, and the molar concentration of the hexamethylenetetramine is 0.01-0.2mol / L L.

[0044] In the present invention, the weight of the mixed solution is not particularly limited, as long as the porous stainless steel can be submerged into the mixed s...

Embodiment 1

[0057] In the present invention, the porous stainless steel is a 316L porous stainless steel tube with an average pore diameter of 1 micron, a thickness of 0.5 mm, a porosity of 30%, and an outer diameter of 1 mm.

[0058] Pretreatment of the porous stainless steel tube: the porous stainless steel tube is cleaned with 5% sodium hydroxide solution and 40% dilute nitric acid solution successively, then washed to neutral with deionized water, finally cleaned with absolute ethanol and heated at 100 Dry at ℃.

[0059] Preparation of composite metal hydrogen separation membrane:

[0060] (1) The above-mentioned processed porous stainless steel tube is immersed in a mixed solution containing water-soluble zinc salt (zinc nitrate 0.1mol / L) and hexamethylenetetramine (0.1mol / L) to carry out the first hydrothermal reaction to obtain A porous stainless steel tube with zinc oxide attached, the conditions of the first hydrothermal reaction include: the reaction temperature is 95°C, and th...

Embodiment 2

[0063] In the present invention, the porous stainless steel is a 316L porous stainless steel tube with an average pore diameter of 1.2 microns, a thickness of 1 mm, a porosity of 40%, and an outer diameter of 4 mm.

[0064] Pretreatment of the porous stainless steel tube: the porous stainless steel tube is cleaned with 5% sodium hydroxide solution and 30% dilute nitric acid solution successively, then washed to neutral with deionized water, finally cleaned with absolute ethanol and heated at 120 Dry at ℃.

[0065] Preparation of composite metal hydrogen separation membrane:

[0066] (1) The above-mentioned processed porous stainless steel tube is immersed in a mixed solution containing water-soluble zinc salt (zinc nitrate 0.1mol / L) and hexamethylenetetramine (0.1mol / L) to carry out the first hydrothermal reaction to obtain A porous stainless steel tube with zinc oxide attached, the conditions of the first hydrothermal reaction include: the reaction temperature is 85°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com