Lithium titanate battery with high safety performance

A lithium titanate battery, safety performance technology, applied in the direction of secondary batteries, battery components, secondary battery gas removal, etc., can solve the problem of affecting battery cycle performance and rate performance, it is difficult to achieve complete coating, diaphragm Insufficient mechanical strength and other problems, to achieve the effect of not being flatulent, improving safety performance, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

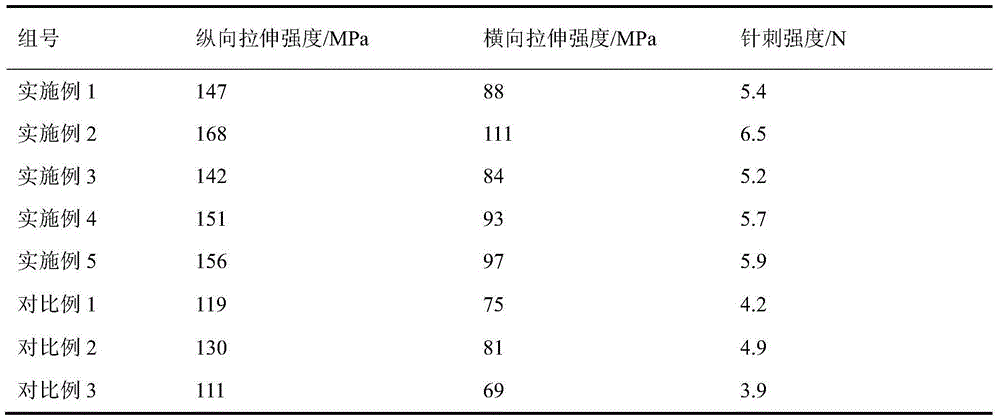

Examples

Embodiment 1

[0029] A lithium titanate battery with a capacity of 20Ah, including a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte, and an aluminum-plastic film outer packaging.

[0030] The active material on the positive electrode sheet is a ternary material, the active material on the negative electrode sheet is lithium titanate, the solvent of the electrolyte is organic carbonate, the electrolyte contains lithium salt, and the electrolyte also contains cyanide chains The mass fraction of the cyanided chain carbonate in the electrolyte is 1.5 wt%, and the mass fraction of the gas scavenger in the electrolyte is 0.75 wt%. The diaphragm has a thickness of 35 microns, a porosity of 45%, and an air permeability of 35 cm 3 / sec non-woven fabric, the diaphragm material is a composite material of polypropylene, halloysite particles, and carboxymethyl cellulose fibers, and the composition content is as follows:

[0031] Polypropylene 80wt%,

[0032] Carboxym...

Embodiment 2

[0042] A lithium titanate battery with a capacity of 20Ah, including a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte, and an aluminum-plastic film outer packaging.

[0043] The active material on the positive electrode sheet is a ternary material, the active material on the negative electrode sheet is lithium titanate, the solvent of the electrolyte is an organic carbonate, the electrolyte contains a lithium salt, and the electrolyte also contains a cyanide ring Like carbonate, the mass fraction of cyanide cyclic carbonate in the electrolytic solution is 2wt%, and the mass fraction of the gas eliminating agent in the electrolytic solution is 1wt%. The diaphragm has a thickness of 50 microns, a porosity of 30%, and an air permeability of 20 cm 3 / sec microporous film, the diaphragm material is a composite material of polyethylene, halloysite particles, and carboxymethyl cellulose fibers, and the composition content is as follows:

[0044] Po...

Embodiment 3

[0055]A lithium titanate battery with a capacity of 20Ah, including a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte, and an aluminum-plastic film outer packaging.

[0056] The active material on the positive electrode sheet is a ternary material, the active material on the negative electrode sheet is lithium titanate, the solvent of the electrolyte is an organic carbonate, the electrolyte contains a lithium salt, and the electrolyte also contains a cyanide ring Like carbonate, the mass fraction of cyanide cyclic carbonate in the electrolytic solution is 1 wt%, and the mass fraction of the gas eliminating agent in the electrolytic solution is 0.5 wt%. The diaphragm has a thickness of 20 microns, a porosity of 55%, and an air permeability of 50 cm 3 / sec non-woven fabric, the diaphragm material is a composite material of polypropylene, halloysite particles, and carboxymethyl cellulose fibers, and the composition content is as follows:

[0057...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com