All-solid-state battery and preparation method thereof

An all-solid-state battery and solid-state electrolyte technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low ionic conductivity of electrolytes, low battery power, etc. performance, the effect of increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]In addition, the preparation method of the above-mentioned all-solid-state battery proposed by the present invention includes:

[0036] Step 1: Mix the positive electrode powder material, acetylene black, graphite, imide, and solid electrolyte powder, and prepare the positive electrode sheet through coating, rolling, and drying;

[0037] Step 2: Thermally evaporate the mixture of carbon powder and lithium phosphate powder on the surface of the positive electrode under nitrogen plasma conditions to deposit a layer of lithium carbon phosphorus oxygen nitrogen solid electrolyte on the surface of the positive electrode, the lithium carbon phosphorus oxygen nitrogen solid electrolyte The chemical formula is Li x C y PO 4-z N z , where x>3,0<y<1,0<z<1; and

[0038] Step 3: Thermally evaporate a layer of metal lithium film on the surface of the lithium carbon phosphorus oxygen nitrogen solid electrolyte to form an all-solid lithium battery.

[0039] Wherein, the lithium ca...

Embodiment 1

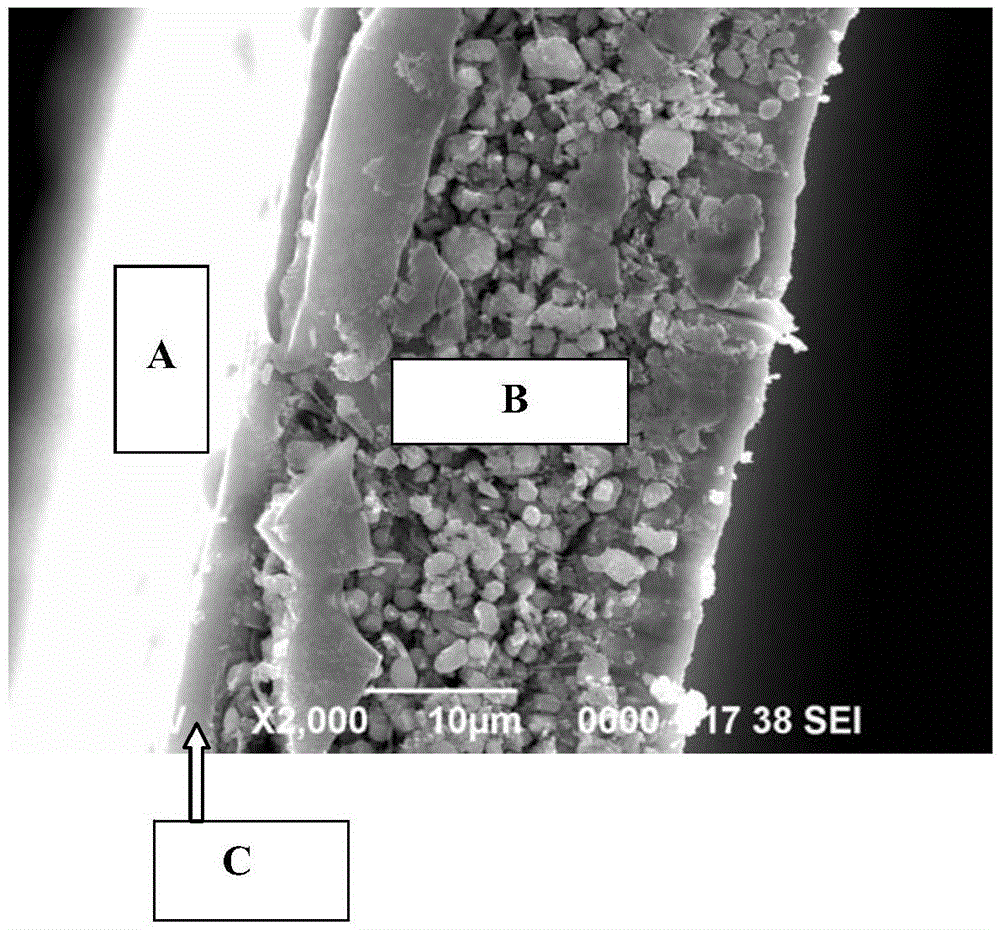

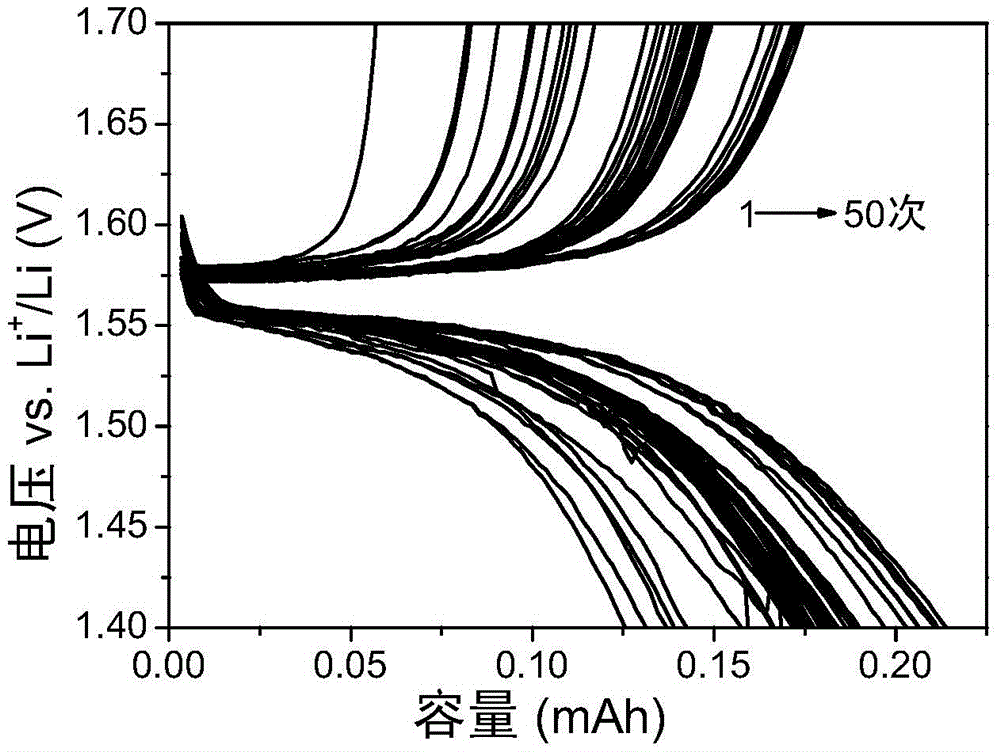

[0051] Commercial cathode powder materials such as Li 4 Ti 5 o 12 , acetylene black, graphite, imide (PAI), solid electrolyte powder (Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 Mix at a mass ratio of 50:3:2:5:40, use N-methylpyrrolidone (NMP) as a solvent, stir to form a uniform positive electrode slurry with a solid content of 50%, and coat the slurry on a 10 μm thick aluminum foil After being rolled and cut, it was dried in a vacuum oven at 120°C for 12 hours to obtain a 30 μm thick positive electrode sheet.

[0052] in Li 4 Ti 5 o 12 A 2 micron thick lithium carbon phosphorus oxygen nitrogen solid electrolyte is deposited on the surface of the positive electrode. The deposition of lithium carbon phosphorus oxygen nitrogen solid electrolyte is a combination of thermal evaporation and nitrogen plasma technology, and the coating is deposited under vacuum conditions, and the vacuum degree can reach 10 -4 Pa, the working gas N is controlled by a mass flow controller 2 The flow r...

Embodiment 2

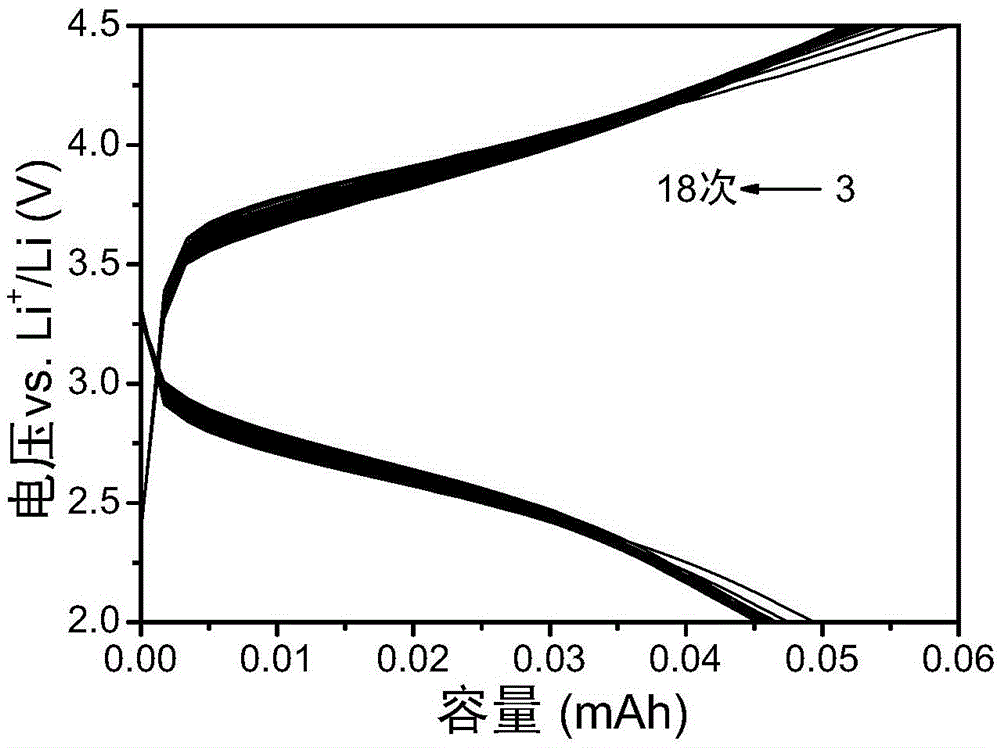

[0056] Commercial cathode powder materials such as LiFePO 4 , acetylene black, graphite, imide (PAI), solid electrolyte powder (Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 Mix at a mass ratio of 50:3:2:5:40, use N-methylpyrrolidone (NMP) as a solvent, stir to form a uniform positive electrode slurry with a solid content of 50%, and coat the slurry on a 10 μm thick aluminum foil After being rolled and cut, it was dried in a vacuum oven at 120 °C for 12 h to obtain a 4 μm thick positive electrode sheet.

[0057] In LiFePO 4 A 2 micron thick lithium carbon phosphorus oxygen nitrogen solid electrolyte is deposited on the surface of the positive electrode. in Li 4 Ti 5 o 12 A 2 micron thick lithium carbon phosphorus oxygen nitrogen solid electrolyte is deposited on the surface of the positive electrode. The deposition of lithium carbon phosphorus oxygen nitrogen solid electrolyte is a combination of thermal evaporation and nitrogen plasma technology, and the coating is deposited under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrochemical stability window | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com