Method for measuring PBB (polybrominated biphenyl) and PBDE (polybrominated diphenyl ether) fire retardants in textile with ultra-high performance liquid chromatography

An ultra-high-efficiency liquid phase and polybrominated biphenyl technology, which is applied in the field of textile detection, can solve the problems of few relevant literatures, few research institutions, and no detection standards for liquid phase method detection, so as to increase export income, reduce enterprise costs, and reduce green The effect of trade barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

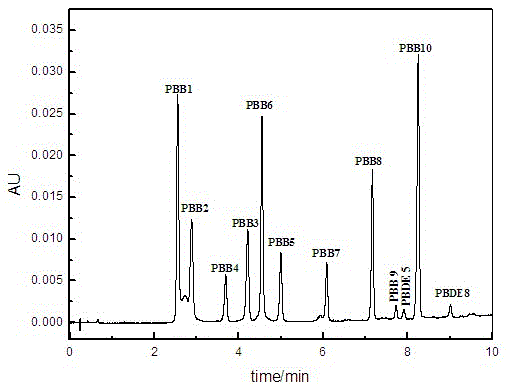

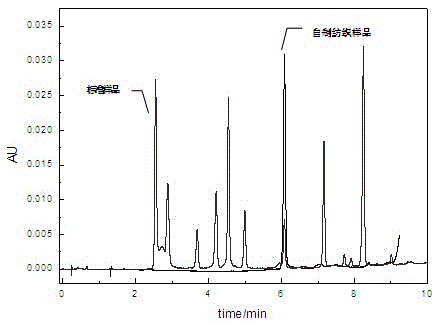

[0023] Below in conjunction with accompanying drawing, the present invention will be further described

[0024] Take the self-made heptabromobiphenyl (PBB7) positive textile sample, cut it into small pieces with a size not exceeding 5mm×5mm, mix well, weigh 1.00g (accurate to 0.01g) of the textile sample, and place it in 50mL Add 20mL of n-hexane-acetone (7+3) to the Erlenmeyer flask with a stopper, extract in an ultrasonic generator for 20min, filter the extract, and extract the residue with 5mL of n-hexane-acetone (7+3) for 20min, and combine The filtrate was collected in a 100mL concentrator bottle, concentrated to near dryness in a water bath rotary evaporator at 40°C, and fixed to 2.0mL with n-hexane-acetone (7+3) solution, and 0.22μm polytetrafluoroethylene organic phase microporous membrane Filter, and filter the extract into a small sample bottle for testing.

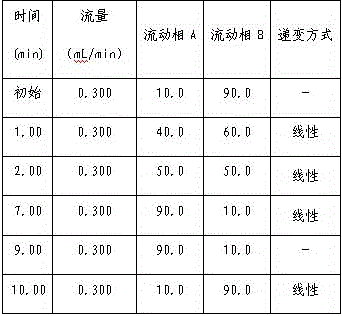

[0025] The sample solution to be tested was determined by high performance liquid chromatography. Chromatog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com