Aluminum alloy cylinder body inner surface ceramic layer and technique thereof

A process method, aluminum alloy technology, applied in the direction of anodic oxidation, etc., can solve the problems of excessive size expansion, difficulty in practical use, large difference in thermal expansion coefficient, etc., and achieve good wear resistance and thermal conductivity, and are not easy to peel and peel off , Improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

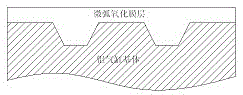

[0015] Embodiment 1: 1P52QMI motorcycle aluminum alloy cylinder inner surface ceramic layer and its process method:

[0016] ①Machining a threaded spiral groove on the inner surface of the aluminum alloy cylinder by machining method, the pitch of the spiral groove is 0.1mm~0.7mm, the cross-sectional shape is trapezoidal, the opening width of the spiral groove is 0.16mm, and the aspect ratio is 1:1.40;

[0017] ② Remove oil from the aluminum alloy cylinder, seal the outer surface and put it into a micro-arc oxidation tank. The oxidation process uses a pulse oxidation power supply. The aluminum alloy cylinder is used as the anode, and the stainless steel is used as the cathode. The area ratio of the anode and the cathode is 1:0.8. The temperature of the oxidizing solution is 10-30°C, and it is in a stirring state. The micro-arc oxidizing solution is an electrolytic solution of a low-alkaline sodium silicate system;

[0018] ③Start the pulse oxidation power supply, the pulse freq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com