Al2O3 modified multiwalled carbon nanotube/epoxy resin composite material and preparation method thereof

A technology of multi-wall carbon nanotubes and epoxy resin, which is applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor performance of composite materials, difficulty in uniform dispersion, and poor resin adhesion, etc., to achieve Improvement of comprehensive performance, increase of wear resistance, and improvement of impedance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] a kind of Al 2 o 3 The preparation method of modified multi-walled carbon nanotube / epoxy resin composite material comprises the following steps:

[0031] (1) Preparation of acidified multi-walled carbon nanotubes

[0032] Weigh multi-walled carbon nanotubes into a beaker, then add concentrated sulfuric acid and concentrated nitric acid mixed acid with a volume ratio of 3:1, ultrasonically oscillate for 1 hour, then transfer to a three-necked flask, stir at 40°C and 200r / min for 12 hours, then use deionized water Dilute, filter with suction, wash with 0.1mol / L sodium hydroxide solution until neutral, and dry at 80°C to obtain acidified multi-walled carbon nanotubes; wherein the weight ratio of multi-walled carbon nanotubes to mixed acid is 1:40; concentrated sulfuric acid The concentration of concentrated nitric acid is 98%, and the concentration of concentrated nitric acid is 95%;

[0033] (2)Al 2 o 3 - Preparation of MWCNTs hybrid materials

[0034] Weigh the aci...

Embodiment 2

[0040] A preparation method of MWCNTs / epoxy composite coating, comprising the following steps:

[0041] (1) Preparation of acidified multi-walled carbon nanotubes

[0042] Weigh multi-walled carbon nanotubes into a beaker, then add concentrated sulfuric acid and concentrated nitric acid mixed acid with a volume ratio of 3:1, ultrasonically oscillate for 1 hour, then transfer to a three-necked flask, stir at 40°C and 200r / min for 12 hours, then use deionized water Dilute, filter with suction, wash with 0.1mol / L sodium hydroxide solution until neutral, and dry at 80°C to obtain acidified multi-walled carbon nanotubes; wherein the weight ratio of multi-walled carbon nanotubes to mixed acid is 1:10; concentrated sulfuric acid The concentration of concentrated nitric acid is 98%, and the concentration of concentrated nitric acid is 95%;

[0043] (2) Preparation of modified MWCNTs

[0044] Weigh the acidified multi-walled carbon nanotubes in a beaker, then add anhydrous ethanol / wa...

experiment example

[0048] The surface morphology of the coating was observed by a scanning electron microscope (SEM), the flexibility of the coating was measured by a material testing machine (MTS), and the electrical properties of the coating were tested by EIS.

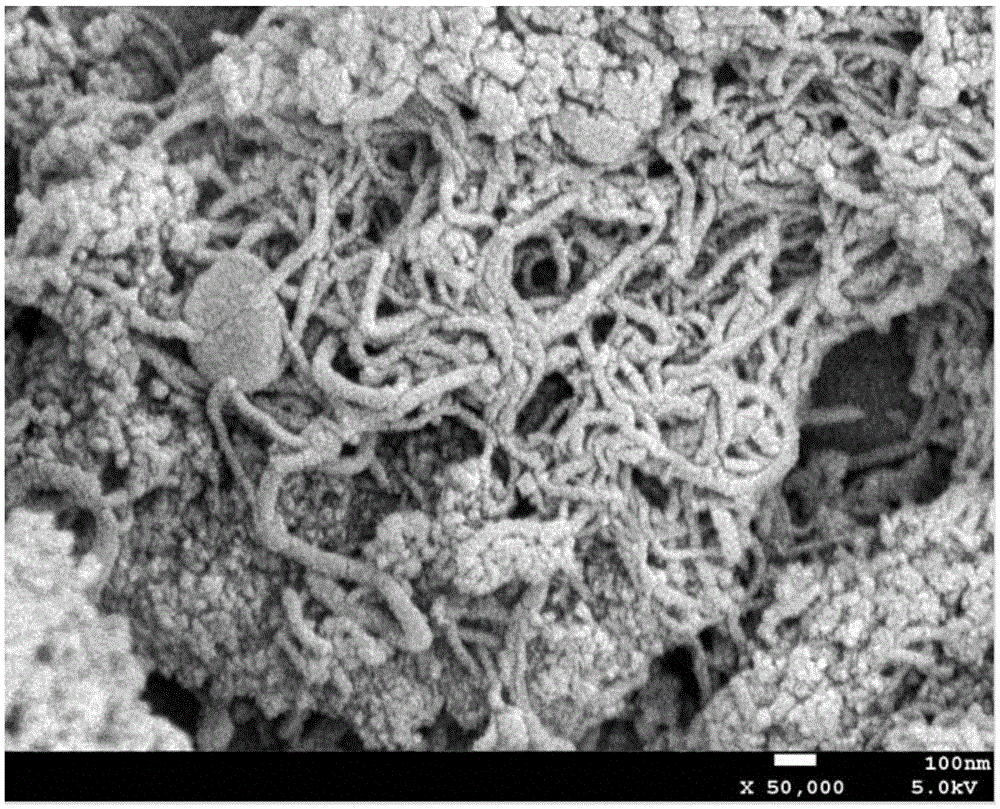

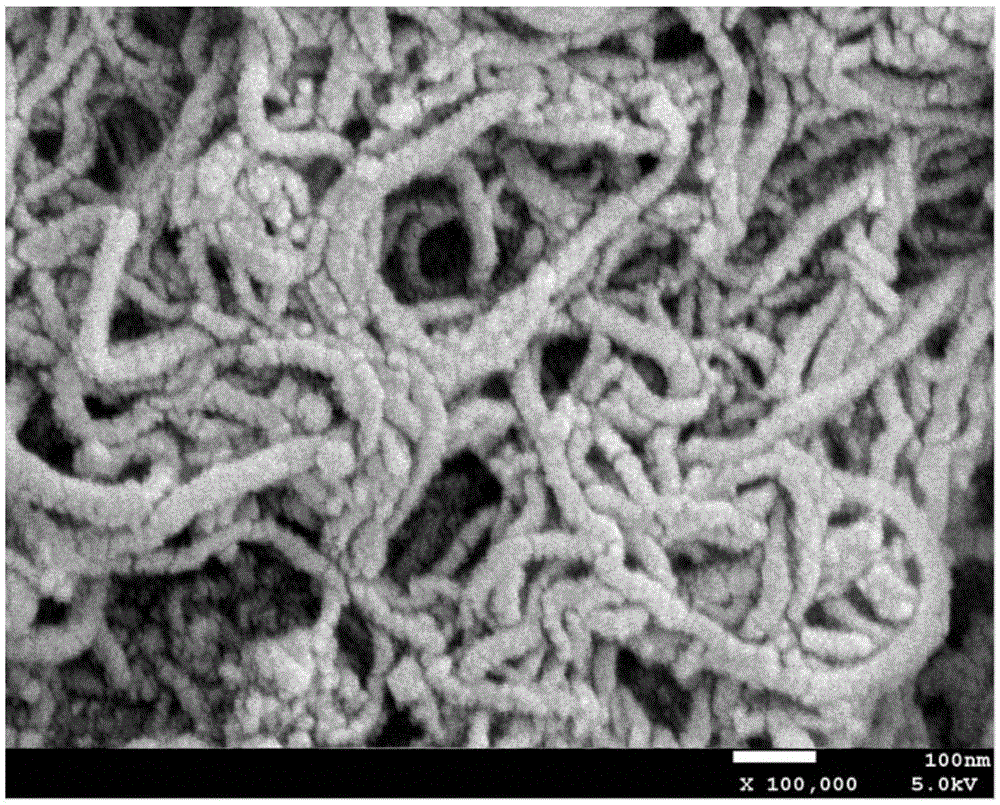

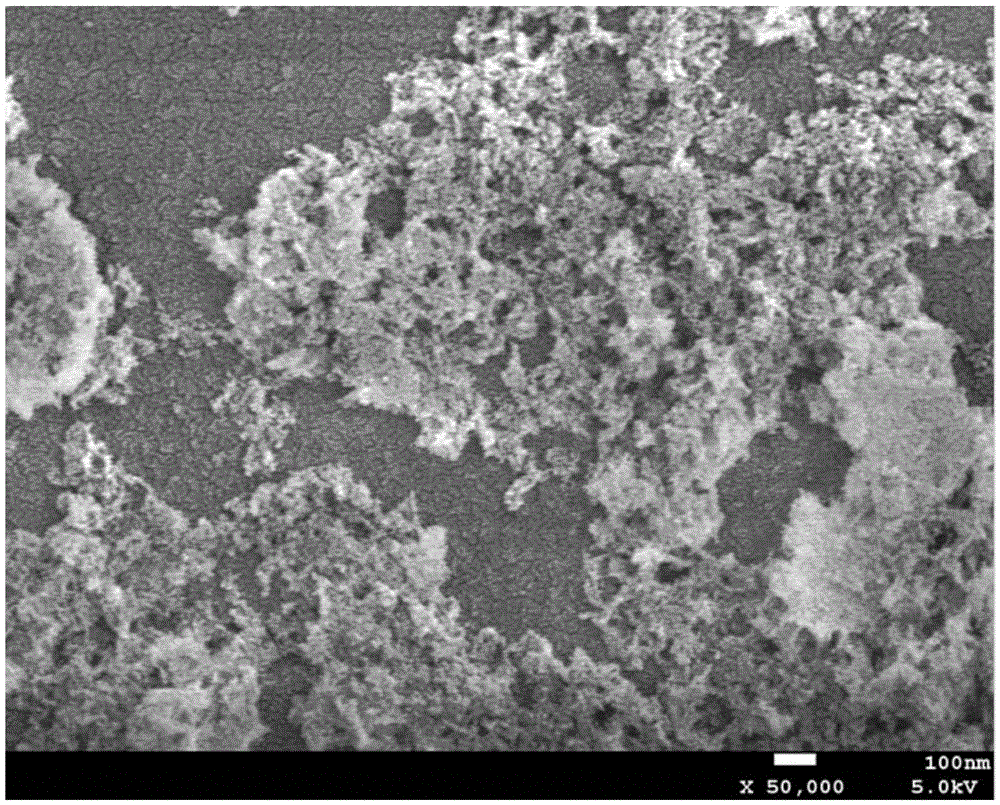

[0049] (1) MWCNTs and Al 2 o 3 -Surface morphology of MWCNTs hybrid materials:

[0050] Depend on Figure 1-4 It can be seen that Al 2 o 3 Before coating, the multi-walled carbon nanotubes had a perfect tubular structure. After alumina coating, the surface of the multi-walled carbon nanotubes had sheet-like structures, but the shape of the tubular structure remained, indicating that the coating process did not destroy the tubular structure of the nanotubes. structure, the difference is that at this time it can be clearly seen that a layer of material is covered on the surface of the nanotube. In addition, it can also be seen from the figure that Al 2 o 3 -The agglomeration of MWCNTs hybrid materials is also reduced a lot, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com