Low-viscosity thermosetting polyimide resin and preparation method and application thereof

A polyimide resin, thermosetting technology, applied in the field of low viscosity thermosetting polyimide resin and its preparation, can solve the problems of poor solubility, limit polyimide processing and application, high melt viscosity, etc., and achieve low melting Viscosity, easy proportioning of reaction raw materials, and the effect of reducing melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

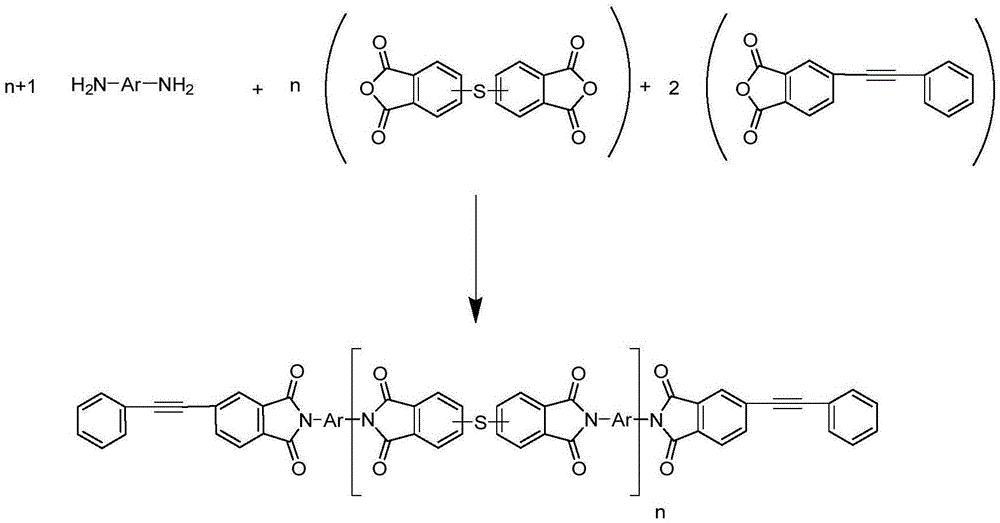

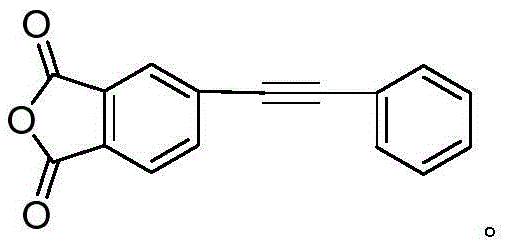

Method used

Image

Examples

Embodiment 1

[0047] In this example, the mixed thioether dianhydride contains three structures of 3,3'-TDPA, 3,4'-TDPA and 4,4'-TDPA. Wherein the molar ratio is n(3,3'-TDPA):n(3,4'-TDPA):n(4,4'-TDPA)=17:58:25.

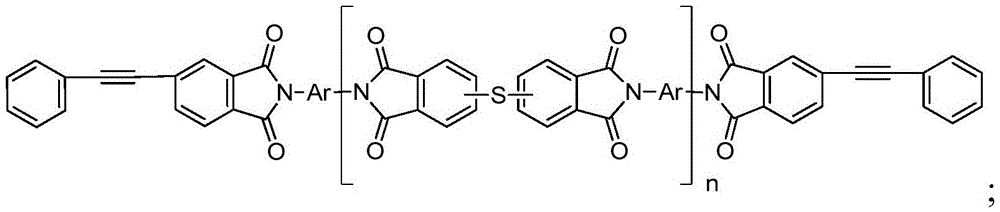

[0048] In this embodiment, the polyimide resin has the following structural formula:

[0049]

[0050] Add 4.0048g (0.02mol) 4,4′-diaminodiphenyl ether into a dry and clean 100mL three-necked flask, add N-methylpyrrolidone as a solvent, protect it with nitrogen, stir at room temperature, and add 3.2628g (0.01mol) ) mixed thioether dianhydride, reacted for 5 hours and then added 4.9648 g (0.02 mol) of end-capping agent 4-phenylacetylene phthalic anhydride, added N-methylpyrrolidone until the solid content of the solution was 30%, and continued to react for 10 hours. Add 10ml of toluene to the solution and raise the temperature to 180°C. Reflux with water for 2h. Release the toluene in the water separator, and when the toluene condensed in the water separator reaches about 10ml...

Embodiment 2

[0054] In this example, the mixed thioether dianhydride contains three structures of 3,3'-TDPA, 3,4'-TDPA and 4,4'-TDPA. Wherein the molar ratio is n(3,3'-TDPA):n(3,4'-TDPA):n(4,4'-TDPA)=15:61:24.

[0055] In this embodiment, the polyimide resin has the following structural formula:

[0056]

[0057] Add 4.8058g (0.024mol) 4,4'-diaminodiphenyl ether into a dry and clean 100mL three-necked flask, add N-methylpyrrolidone as a solvent, protect it with nitrogen, stir at room temperature, and add 6.5256g (0.02mol) ) mixed thioether dianhydride, reacted for 4 hours and then added 1.9859 g (0.008 mol) of end-capping agent 4-phenylacetylene phthalic anhydride, added N-methylpyrrolidone until the solid content of the solution was 30%, and continued to react for 12 hours. Add 10ml of toluene to the solution, raise the temperature to 180°C, and reflux with water for 3h. Release the toluene in the water separator, and when the toluene condensed in the water separator reaches about 10...

Embodiment 3

[0061] In this example, the mixed thioether dianhydride contains three structures of 3,3'-TDPA, 3,4'-TDPA and 4,4'-TDPA. Wherein the molar ratio is n(3,3'-TDPA):n(3,4'-TDPA):n(4,4'-TDPA)=19:54:27.

[0062] In this embodiment, the polyimide resin has the following structural formula:

[0063]

[0064] Add 6.4077g (0.032mol) 4,4'-diaminodiphenyl ether into a dry and clean 100mL three-necked flask, add N-methylpyrrolidone as a solvent, protect it with nitrogen, stir at room temperature, and add 9.1358g (0.028mol) ) mixed with thioether dianhydride, after 5 hours of reaction, 1.9857 g (0.008 mol) of 4-phenylacetylene phthalic anhydride was added, and N-methylpyrrolidone was added until the solid content of the solution was 30%, and the reaction was continued for 10 hours. Add 10ml of toluene to the solution and raise the temperature to 180°C. Reflux with water for 2h. Release the toluene in the water separator, and when the toluene condensed in the water separator reaches ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com