Preparation method of bio-based bisphenol or polycarbonate material

A polycarbonate, bio-based technology, applied in the field of synthesis of bio-based polycarbonate materials, can solve the problems affecting the synthesis of polycarbonate, and achieve the effect of good low toxicity and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

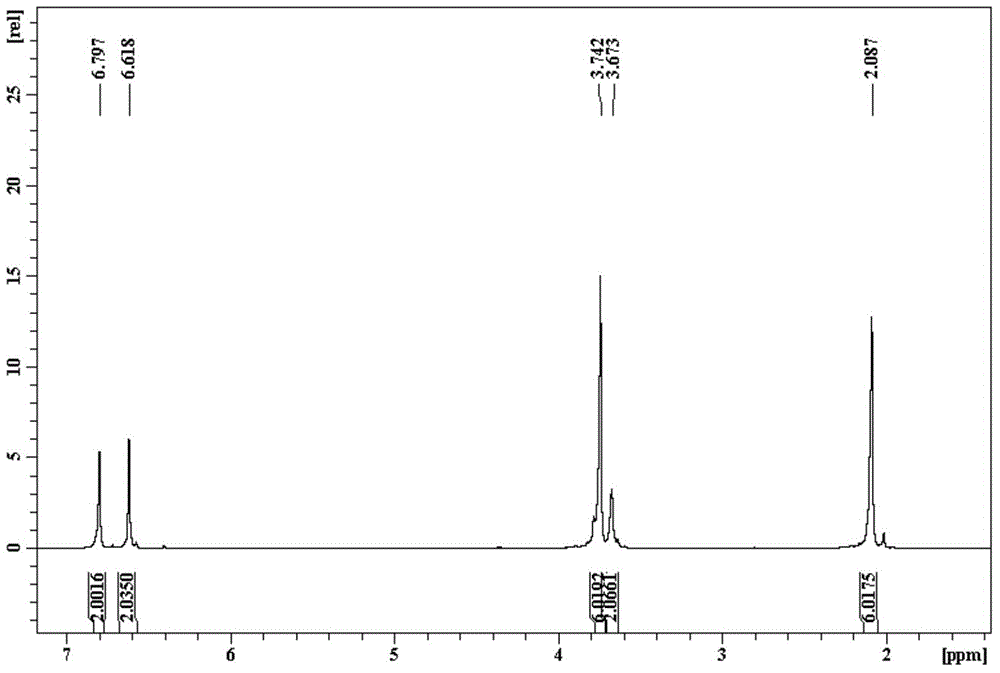

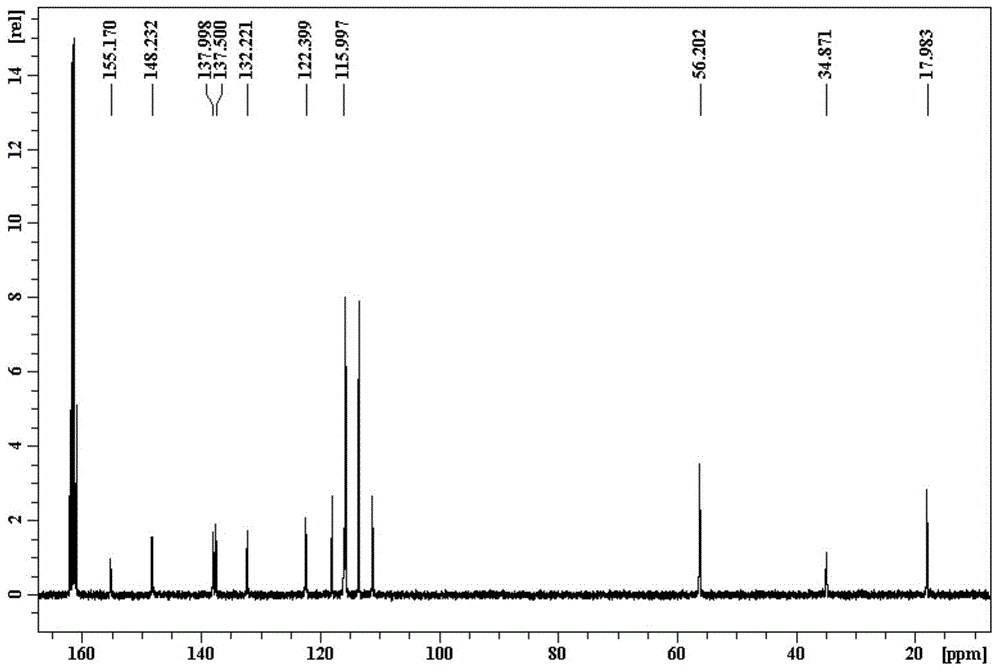

Embodiment 1

[0041] Add methylguaiacol (2 mmol), formaldehyde (1 mmol) and 2 ml of water into a single-necked flask, add ligninsulfonic acid (0.4 mmol), and place in an oil bath at 100°C under nitrogen protection to reflux 6h, centrifuge after the reaction, wash the precipitate with 95% ethanol, use petroleum ether and ethyl acetate (volume ratio 3:1) as the eluent, and separate through the column to obtain bio-based bisphenol, 5-5'- Methylenebis(2-methoxy-4-methylphenol), yield 48.9%, melting point 135-138°C, 1 HNMR (500MHzDMSO-d 6 ), δ=8.54(s,2H),6.73(s,2H),6.30(s,2H),3.72(s,6H),3.57(s,2H),2.09(s,6H). 13 CNMR (125MHzDMSO-d 6 ), δ=145.5, 144.2, 130.8, 126.0, 116.6, 114.4, 55.7, 34.6, 18.6.FT-IR(KBr)νmax(cm- 1 ) 1078, 1196 (C-O); 1446, 1511, 1595 (aromatic); 2956, 3458, 3528 (O-H).HRMScalcdforC 17 h 20 o 4 Na[M+Na] + :311.1259,found311.1252.

[0042] The type of catalyst has an important influence on the synthesis of bio-based bisphenol monomers, which we illustrate through the fol...

Embodiment 2

[0044] Add methylguaiacol (2 mmol), formaldehyde (1 mmol) and 2 ml of water into a single-necked flask, add Bronsted acid catalyst (0.2 mmol), and place in an oil bath at 100°C under nitrogen protection Reflux for 3 hours, centrifuge after the reaction, wash the precipitate with ethanol with a mass concentration of 95%, use petroleum ether and ethyl acetate (volume ratio 3:1) as the eluent, and separate through the column to obtain bio-based bisphenol, 5-5' -Methylene bis(2-methoxy-4-methylphenol), the specific results are as follows:

[0045]

[0046] The amount of catalyst used and the reaction time have an important impact on the synthesis of bio-based bisphenol monomers, which we illustrate through the following comparative examples.

Embodiment 3

[0048] Add methylguaiacol (2 mmoles), formaldehyde (1 mmoles) and 2 milliliters of water into the single-necked flask, add Bronsted acid catalyst (add relative to the molar number of methyl guaiacols), set Reflux under nitrogen protection in an oil bath at 100°C for 3 hours, centrifuge and filter after the reaction, wash the precipitate with ethanol with a mass concentration of 95%, use petroleum ether and ethyl acetate (volume ratio 3:1) as eluent, and separate through a column to obtain Bio-based bisphenol, 5-5'-methylene bis(2-methoxy-4-methylphenol), the specific results are as follows:

[0049]

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com