Water-based antirust agent and preparation method thereof

A water-based anti-rust agent and technology of anti-rust agent, applied in the field of metal anti-rust, can solve the problems of short anti-rust period, environmental pollution, poor anti-rust effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

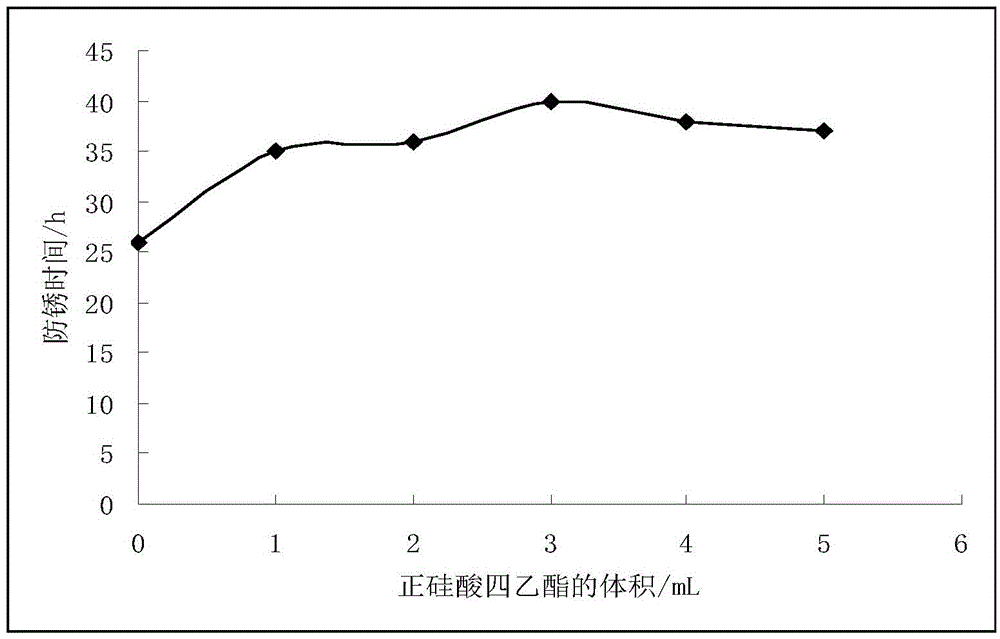

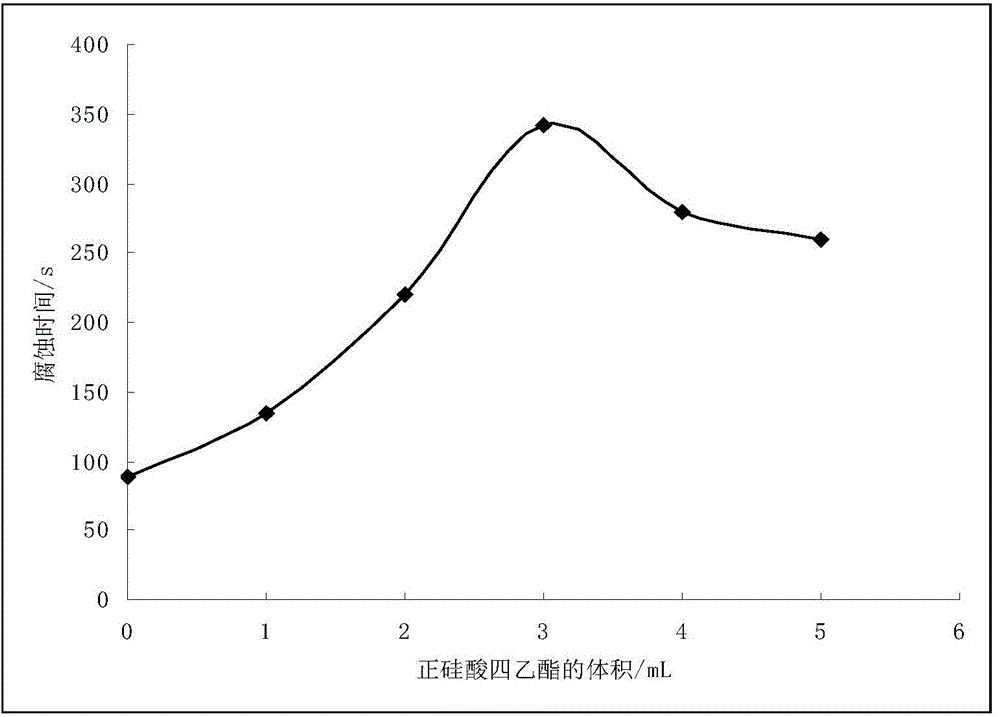

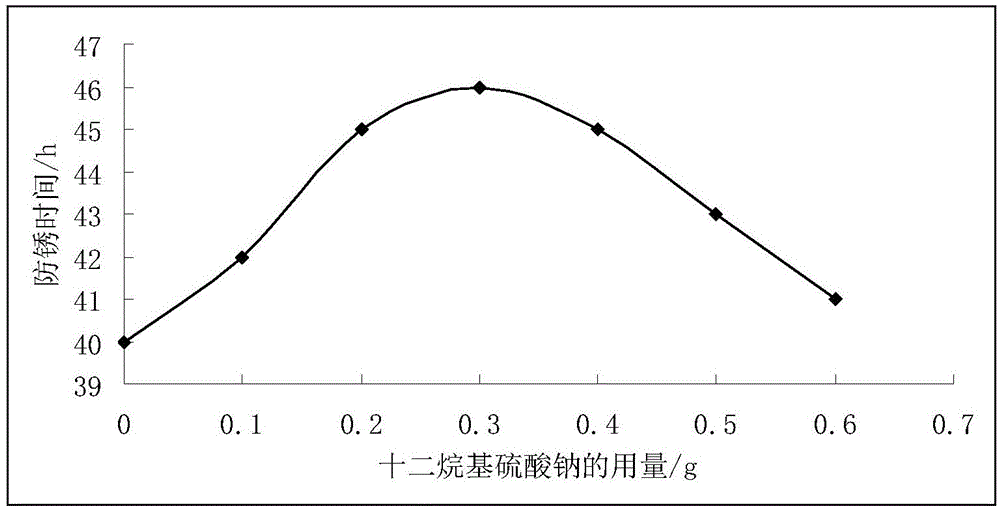

[0064] (1) Add 50mL of water, 0.1mL of triethanolamine, 0.05g of boric acid, 0.08g of ethylenediaminetetraacetic acid, and 0.40g of sodium tungstate to a 50mL sodium silicate solution (600g / L). Stir in a constant temperature water bath;

[0065] (2) Add 1 mL of tetraethyl orthosilicate to the preparation system, then add 0.1 g of sodium lauryl sulfate, and stir at constant temperature for 30 min.

[0066] The anti-rust time of the prepared sample was 35 hours, and the anti-corrosion time of copper sulfate was 135 s.

Embodiment 2

[0068] (1) Add 50mL of water, 0.1mL of diethanolamine, 0.08g of boric acid, 0.06g of ethylenediaminetetraacetic acid, and 40g of sodium tungstate to 50mL of sodium silicate solution (600g / L) in a beaker, at a constant temperature of 80°C stirring in a water bath;

[0069] (2) Add 2 mL of tetraethyl orthosilicate to the preparation system, then add 0.1 g of sodium dodecylsulfonate, and stir at constant temperature for 30 min.

[0070] The anti-rust time of the prepared sample was 36 hours, and the anti-corrosion time of copper sulfate was 220 s.

Embodiment 3

[0072] (1) Add 50mL water, 0.1mL triethylamine, 0.8g boric acid, 1.5g ethylenediaminetetraacetic acid, 0.8g sodium tungstate to 50mL sodium silicate solution (400g / L) Stirring in a constant temperature water bath;

[0073] (2) Add 3 mL of tetraethyl orthosilicate to the preparation system, then add 0.1 g of sodium lauryl sulfate, and stir at constant temperature for 30 min.

[0074] The anti-rust time of the prepared sample is 40h, and the anti-corrosion time of copper sulfate is 342s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com