Special slurry for printing wallpaper having 3D stereo transparent streamer effect and preparation method for special slurry

A slurry and three-dimensional technology, applied in the direction of coating, etc., can solve the problems of opacity, cover the pattern below, limit the three-dimensional aesthetics of wallpaper pattern, affect the color of wallpaper and environmental protection performance, etc., to achieve strong water solubility and water retention , Improve the transfer effect, improve the fluidity and adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

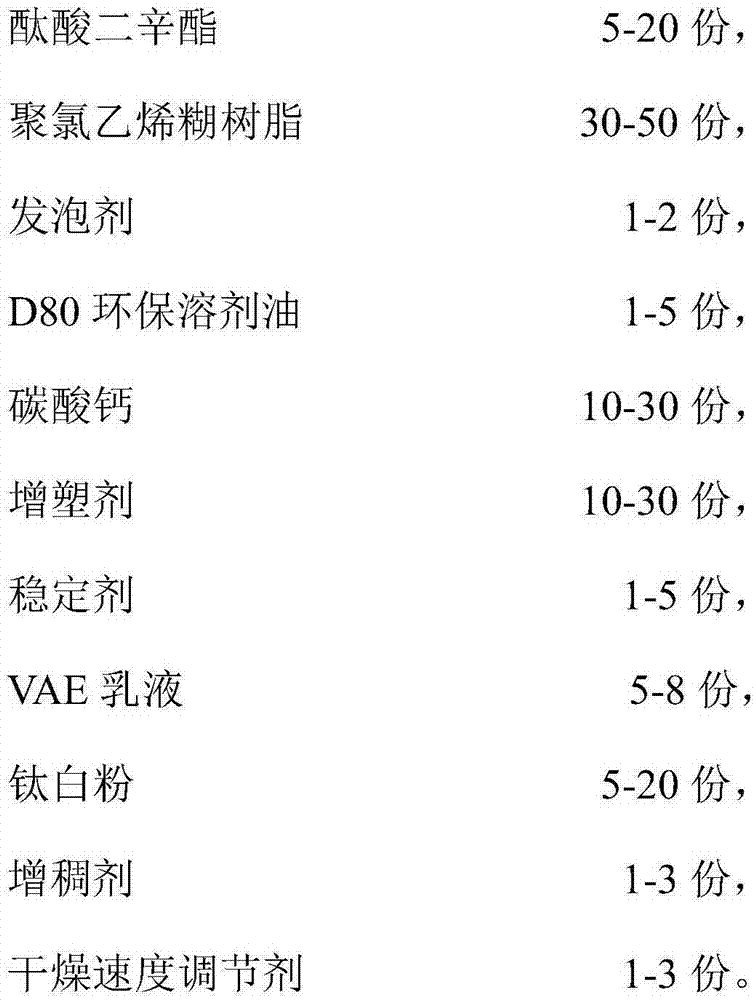

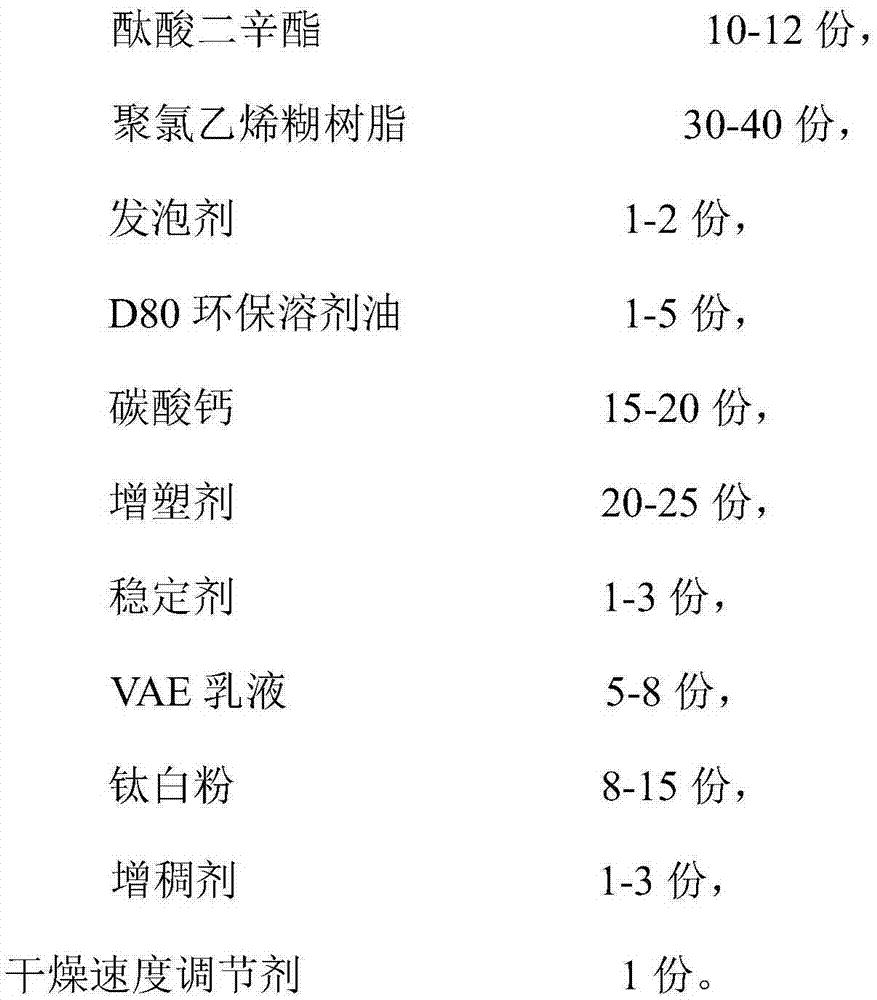

Method used

Image

Examples

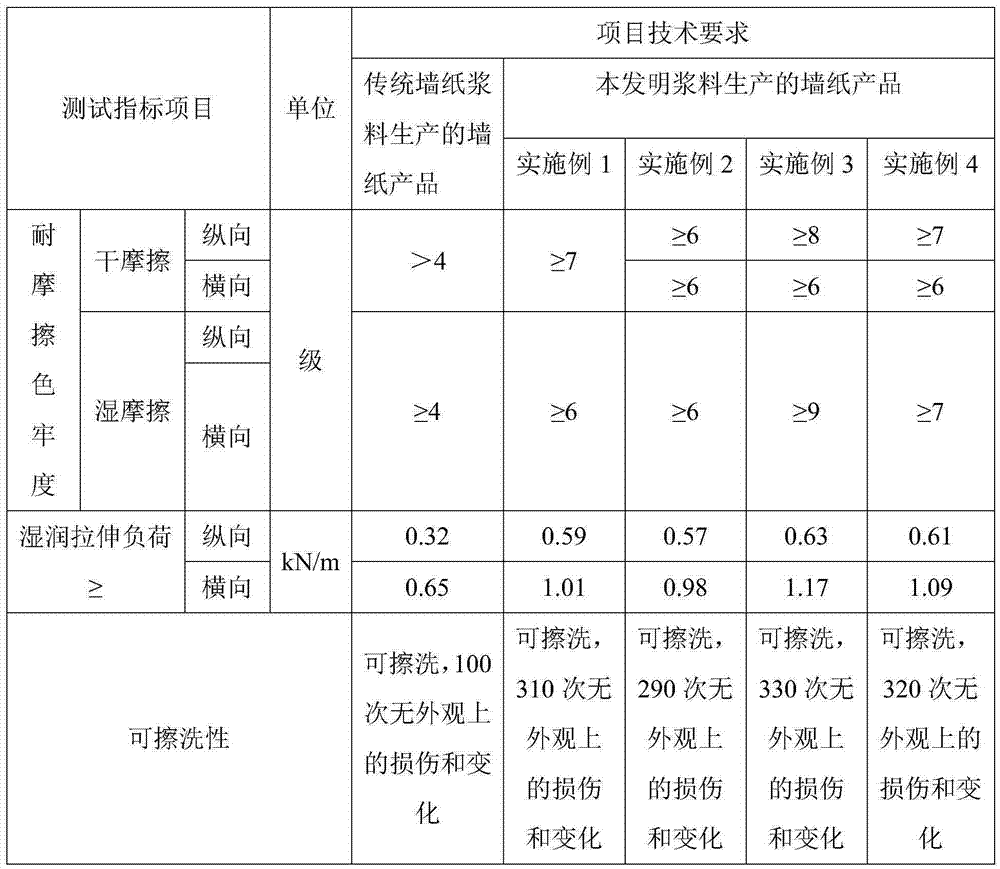

Embodiment 1

[0029] A preparation method of wallpaper printing special slurry with 3D three-dimensional transparent water flow pattern effect, comprising the following preparation steps in sequence:

[0030] Step A: Add 10 parts of dioctyl phthalate into the mixing tank, then add 40 parts of polyvinyl chloride paste resin and stir evenly;

[0031] Step B: 2 parts of AC-410, 3 parts of D80 environmentally friendly solvent oil, 20 parts of calcium carbonate, 20 parts of epoxy soybean oil, 2 parts of potassium zinc composite stabilizer, 8 parts of VAE emulsion, 10 parts Add one portion of titanium dioxide into the mixing tank, keep the rotation speed above 2000-2500r / min, and stir evenly;

[0032] Step C: Add 1 part of lithium magnesium silicate and 1 part of n-butanol into the mixing tank and stir evenly; among them, the manufacturer of magnesium lithium silicate is Guangzhou Bofeng Chemical Technology Co., Ltd., and the manufacturer of n-butanol is Guangzhou Juhui Chemical Co., Ltd.;

[0...

Embodiment 2

[0035] Step A: Add 10 parts of dioctyl phthalate into the mixing tank, then add 30 parts of polyvinyl chloride paste resin and stir evenly;

[0036] Step B: sequentially mix 1 part of AC-410, 1 part of D80 environmentally friendly solvent oil, 15 parts of calcium carbonate, 20 parts of epoxy soybean oil, 1 part of potassium zinc composite stabilizer, 5 parts of VAE emulsion and 8 parts Add one portion of titanium dioxide into the mixing tank, keep the speed at 2000-2500r / min, and stir evenly;

[0037] Step C: Add 2 parts of lithium magnesium silicate and 1 part of propylene glycol into the mixing tank, and stir evenly to obtain a slurry product; wherein, the manufacturer of propylene glycol is Guangzhou Juhui Chemical Co., Ltd.;

[0038] Step D: Finally, 28% gold powder (based on the total weight of the slurry product as 100%) is added to the slurry, and stirred evenly to obtain the product;

[0039] Step E: Adjust the temperature of the oven to 200°C, apply the evenly stirre...

Embodiment 3

[0041] Step A: Add 10 parts of dioctyl phthalate into the mixing tank, then add 35 parts of polyvinyl chloride paste resin and stir evenly;

[0042]Step B: 1 part of AC-410, 3 parts of D80 environmentally friendly solvent oil, 15 parts of calcium carbonate, 25 parts of epoxy soybean oil, 3 parts of potassium zinc composite stabilizer, 6 parts of VAE emulsion, 15 parts Add one portion of titanium dioxide into the mixing tank, keep the speed at 2000-2500r / min, and stir evenly;

[0043] Step C: Add 3 parts of magnesium aluminum silicate and 1 part of propylene glycol into the mixing tank, and stir evenly to obtain a slurry product; wherein, the manufacturer of magnesium aluminum silicate is Guangzhou Bofeng Chemical Technology Co., Ltd.;

[0044] Step D: Finally, 25% silver powder (based on the total weight of the slurry product as 100%) is added into the slurry and stirred evenly.

[0045] Step E: Adjust the temperature of the oven to 200°C, apply the evenly stirred slurry on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com